Pressing equipment

A technology for lamination equipment and lamination boards, which is applied in the directions of lamination, lamination devices, and layered products, and can solve problems such as uneven lamination and sheet warpage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

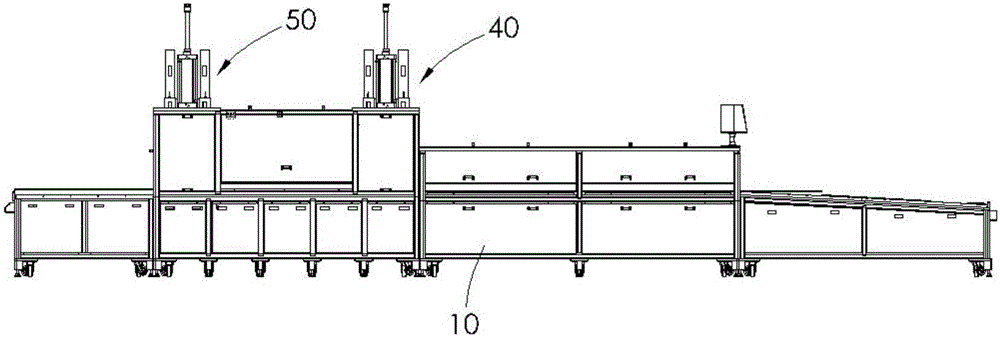

[0032] to combine figure 1 , figure 2 , a pressing equipment, including a frame 10, a roller conveyor track 20, a carrier 30, a front pressing station 40, and a rear pressing station 50.

[0033] to combine figure 1 , figure 2 , the roller conveyor track 20 is installed horizontally on the frame.

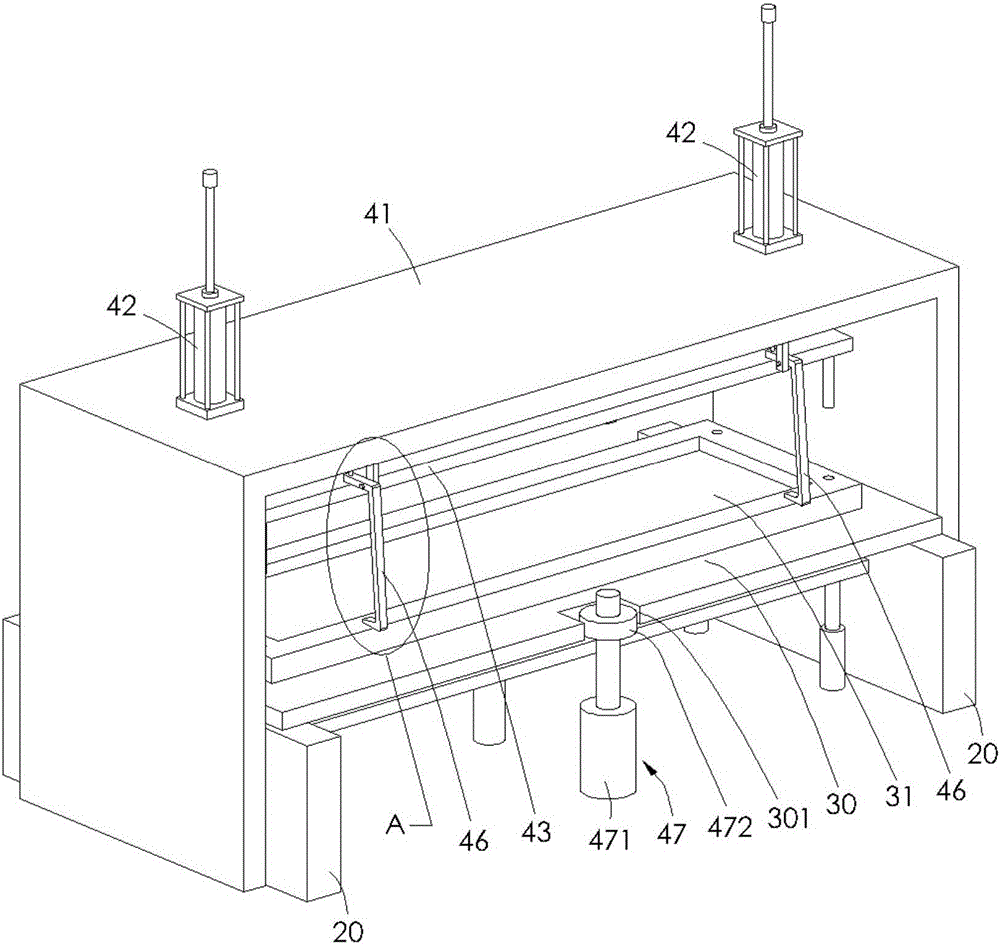

[0034] Such as image 3 , a square opening 301 is opened on the carrier 30 . Such as Figure 5 , four positioning holes 302 are defined at the four corners of the carrier 30 .

[0035] Such as image 3 , the carrier 30 includes a bearing groove 31 for carrying plates, and the carrier runs linearly on the roller conveying track.

[0036] to combine image 3 , Figure 4 , Figure 5, the front stage pressing station 40 includes a first bracket plate 41, a first pressing cylinder 42, a first pressing plate 43, a first lifting cylinder 44, a first lifting plate 45, four sets of first hook devices 46, a first Limiting device 47. The first support plate is arranged horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com