Tengxian rice cake pressing device

A technology of rice cakes and installation blocks, which is applied in the field of pressing devices, can solve the problems of low efficiency, inconvenient collection of rice cakes, time-consuming and labor-intensive problems, and achieve the effect of improving efficiency and reducing manual operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

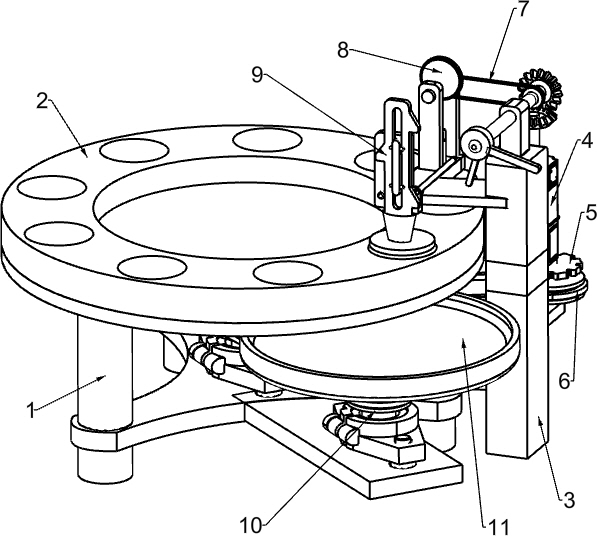

[0047] A kind of Fuji County rice cake pressing device, such as figure 1 As shown, it includes a base 1, a workbench 2, a support frame 3, a biaxial motor 4, an intermittent rotation mechanism 5, and a pressing mechanism 8. A circular groove, a support frame 3 is installed on the right front side of the base 1, a biaxial motor 4 is arranged on the upper part of the rear side of the support frame 3, an intermittent rotation mechanism 5 is arranged on the lower part of the rear side of the support frame 3 and the bottom of the base 1, and the intermittent rotation mechanism 5 and The workbench 2 and the biaxial motor 4 are all connected, and a pressing mechanism 8 is installed on the left upper part and the top of the support frame 3, and the pressing mechanism 8 is connected with the biaxial motor 4.

[0048] When rice cakes need to be pressed, the steamed glutinous rice and cake stuffing are manually placed in the circular groove on the workbench 2, and then the biaxial motor ...

Embodiment 2

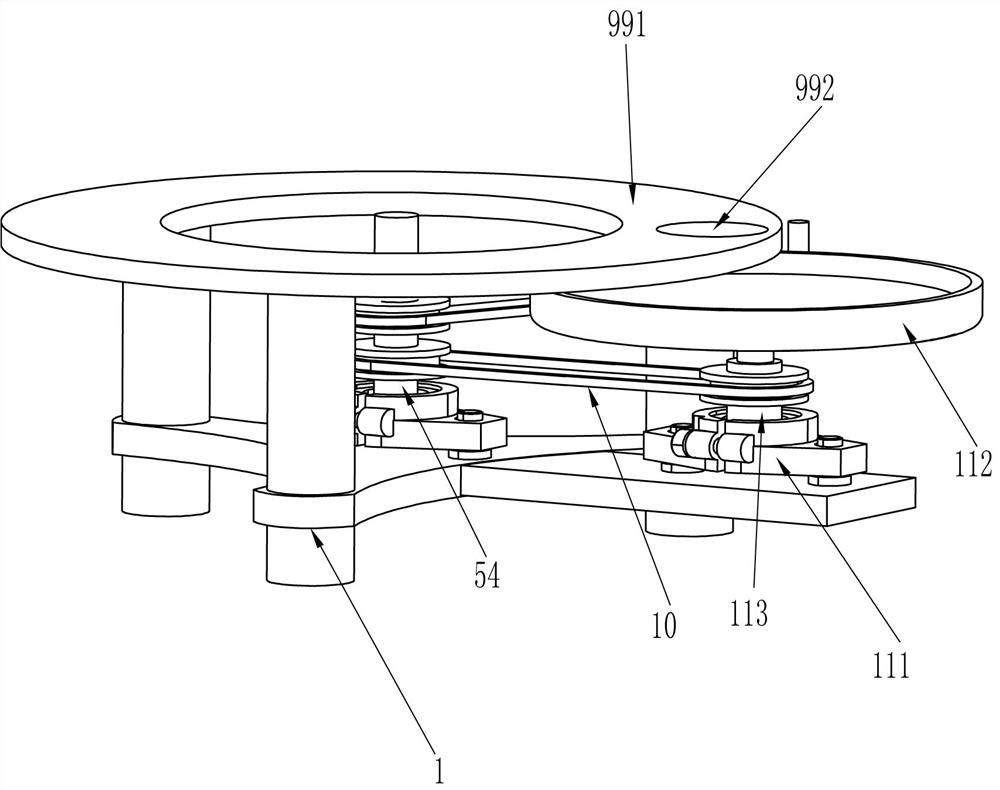

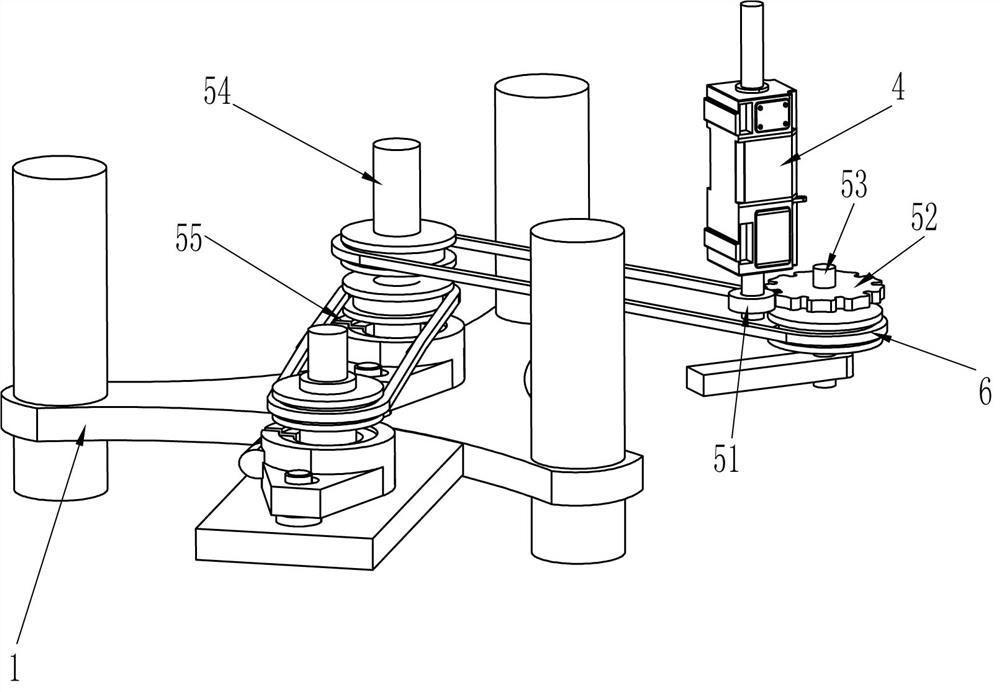

[0050] Specifically, such as Figure 1-3 and Figure 5-6 As shown, the intermittent rotation mechanism 5 includes a missing gear 51, a full gear 52, a first rotating shaft 53, a second rotating shaft 54, a first bearing seat 55 and a first belt transmission assembly 6, and the output shaft on the lower side of the biaxial motor 4 is provided with There is a missing gear 51, and the first rotating shaft 53 is installed in a rotating manner on the lower part of the rear side of the support frame 3. The first rotating shaft 53 is located below the biaxial motor 4. The first rotating shaft 53 top is provided with a full gear 52. The missing gear 51 can be combined with the full gear 52. meshing, the bottom center of the base 1 is provided with a first bearing seat 55, and a second rotating shaft 54 is installed in the first bearing seat 55, the top of the second rotating shaft 54 is connected with the bottom of the workbench 2, the middle part of the second rotating shaft 54 ...

Embodiment 3

[0055] according to figure 1 and Figure 4-5 As shown in the diagram, it also includes a poking mechanism 9, which includes a concentric circle 91, a long rod 92, a short rod 93, a fixed plate 94, a sliding sleeve 95, a poking plate 96, a fixed rod 97, a third installation Block 98, L-shaped rod 99, fixed block 990 and poking material platform 991, the third rotating shaft 82 front ends are equipped with concentric circles 91, the right side of concentric circles 91 is provided with long rods 92, the bottom of concentric circles 91 is connected with short rods 93 , the front side of the guide sleeve 84 is equipped with a fixed plate 94, the middle part of the front side of the fixed plate 94 is provided with a fixed rod 97, the fixed rod 97 is slidably provided with a sliding sleeve 95, the sliding sleeve 95 can be contacted with the long rod 92, and the fixed plate 94 is on the right The third mounting block 98 is installed on the lower part of the side, and the front side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com