Vertical axis wind turbine

A wind energy, axis technology, applied in the field of vertical axis wind turbines, which can solve the problems of wind flow failure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

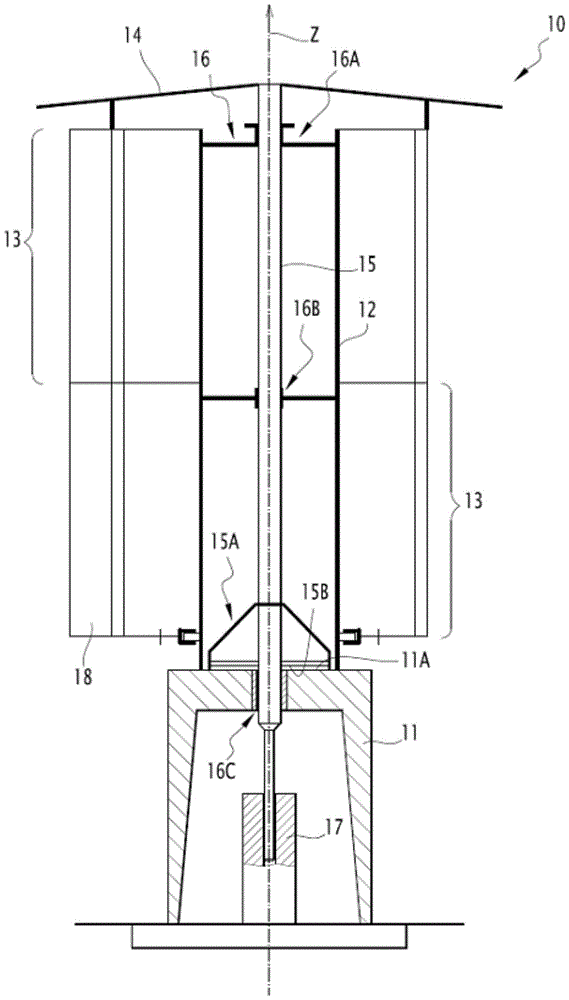

[0042] figure 1 A device 10 for converting wind energy into another type of energy is shown. In the example described, the other type of energy is electrical energy. Alternatively, however, another type of energy here may also be mechanical energy.

[0043] The energy conversion device 10 comprises a base 11 , and a hollow mast 12 mounted on the base 11 and extending along a substantially vertical axis Z.

[0044] According to the example described, a mast 12 is fastened to the structure 11 . The mast 12 is made, for example, of steel, and one or more parts thereof are then attached to the base 11 . Optionally, the mast 12 can be formed by pouring concrete directly on the base 11 using climbing formwork.

[0045] According to another alternative, the mast 12 can be mounted rotatably about a vertical axis Z relative to the base 11 , the reason for this will be explained later.

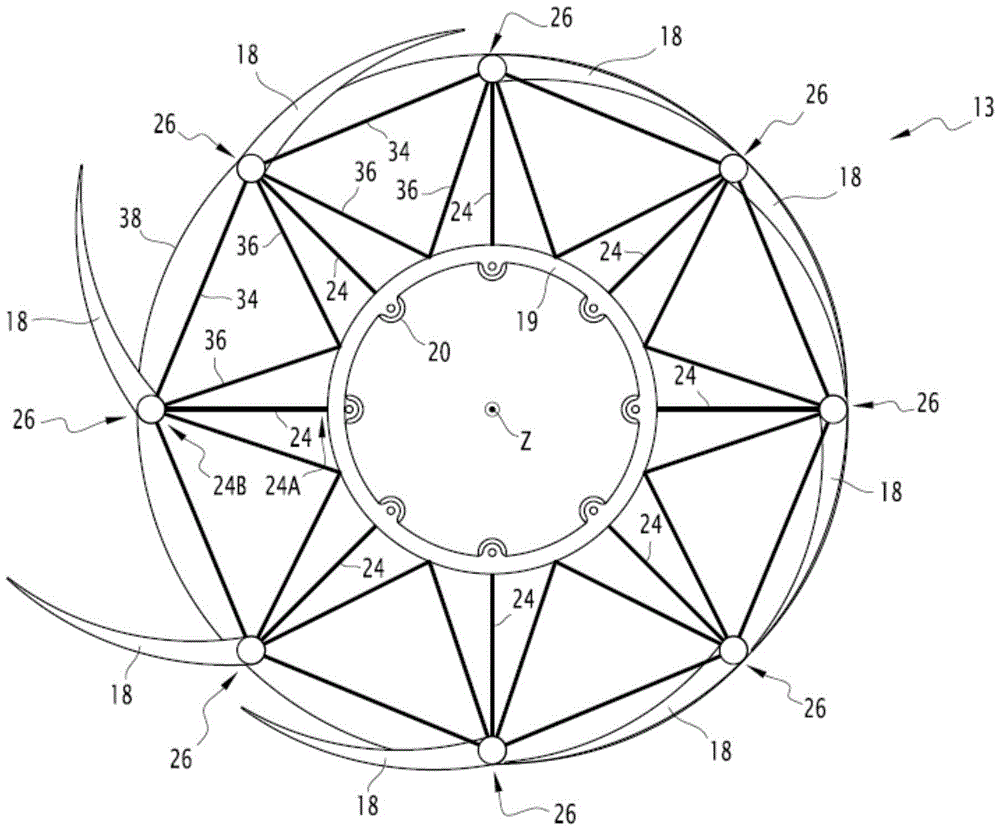

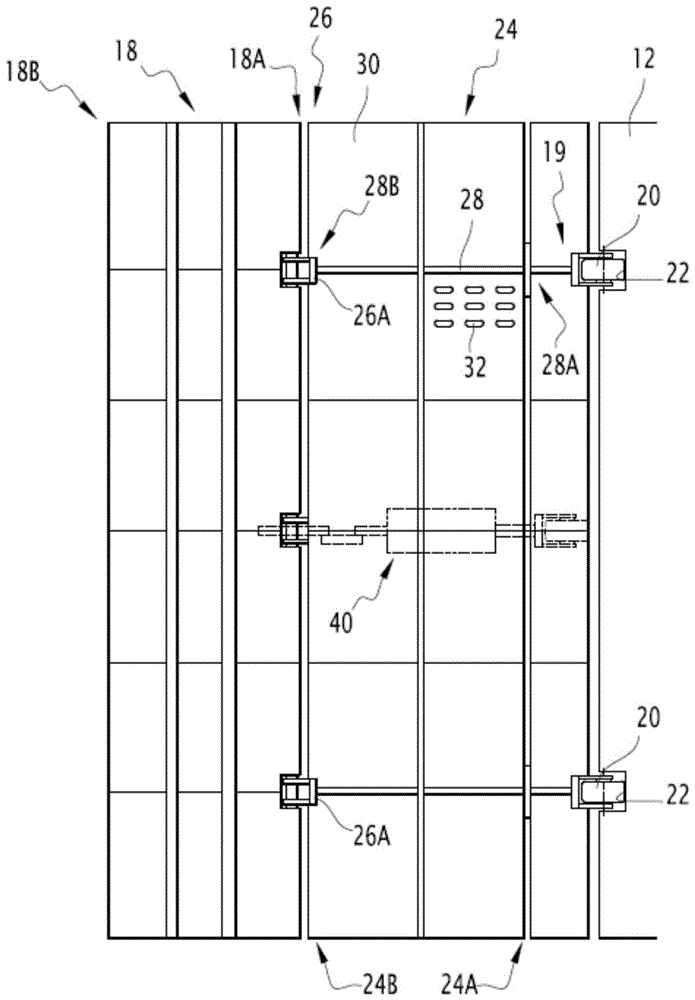

[0046] The energy conversion device 10 comprises at least one module 13 having a substantially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com