A single-shaft double-slip ring mechanism

A slip ring and single shaft technology, applied in the field of single shaft double slip ring mechanism, can solve the problems that cannot meet the actual use requirements, interfere with the measured signal, etc., and achieve the goal of improving market competitiveness, improving transmission quality and prolonging service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

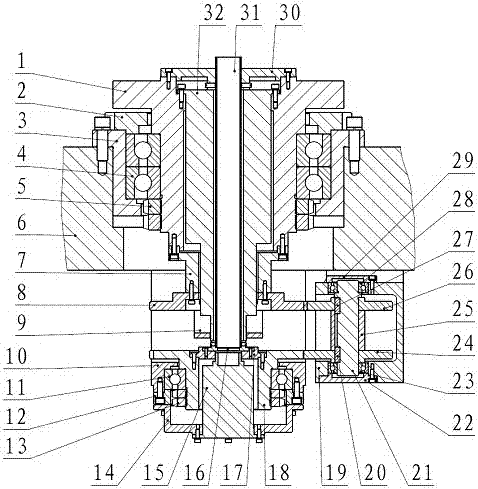

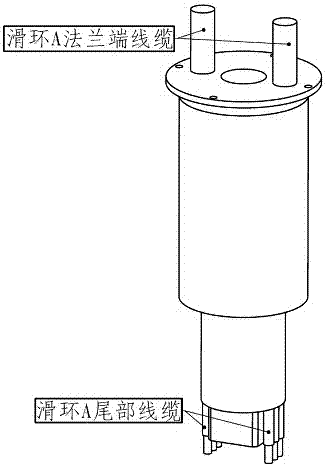

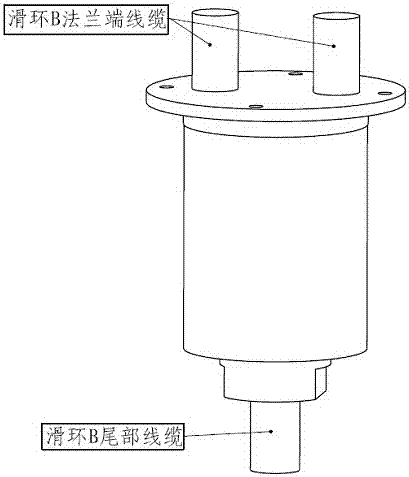

[0035] This embodiment is applicable to the mechanism for isolating strong and weak cables, including: main shaft 1, main bearing end cover 2, bearing seat 3, main shaft bearing 4, main lock nut 5, base body 6, encoder mounting shaft 7, active Gear 8, slip ring A fixed frame 9, adapter bracket 10, driven gear bearing 11, auxiliary bearing end cover 12, auxiliary lock nut 13, slip ring B bracket 14, slip ring B15, cable tube lower bracket 16, Slip ring B fixed frame 17, driven gear 18, gear box 19, flat key A20, reversing gear shaft 21, lower bearing end cover 22, gear bearing A 23, reversing gear A24, gear spacer 25, reversing gear B26, flat key B27, gear bearing B 28, upper bearing cover 29, cable tube upper bracket 30, cable tube 31, slip ring A32.

[0036] The main shaft 1 is a hollow structure, and forms the main shaft shaft system with the main bearing cover 2, the bearing seat 3, the main shaft bearing 4 and the main lock nut 5, and the bearing seat 3 is fixed on the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com