Annular uniform cross-section flow equalizing apparatus for cylinder wall-attached air supply

A technology with equal cross-section and circular shape, which is applied in the direction of pipeline layout, etc., can solve the problems of application limitations and inapplicability to large-space buildings, and achieve the effects of improving effectiveness, improving the uniformity of air outlet, and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

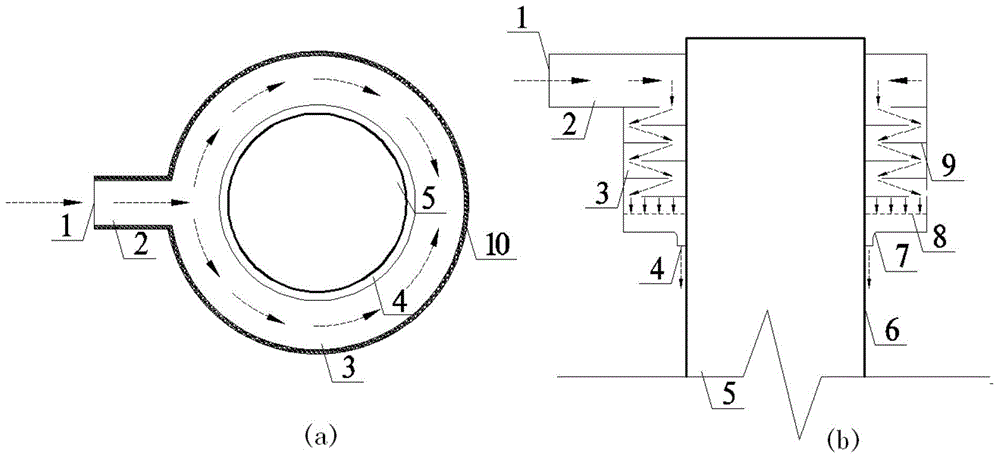

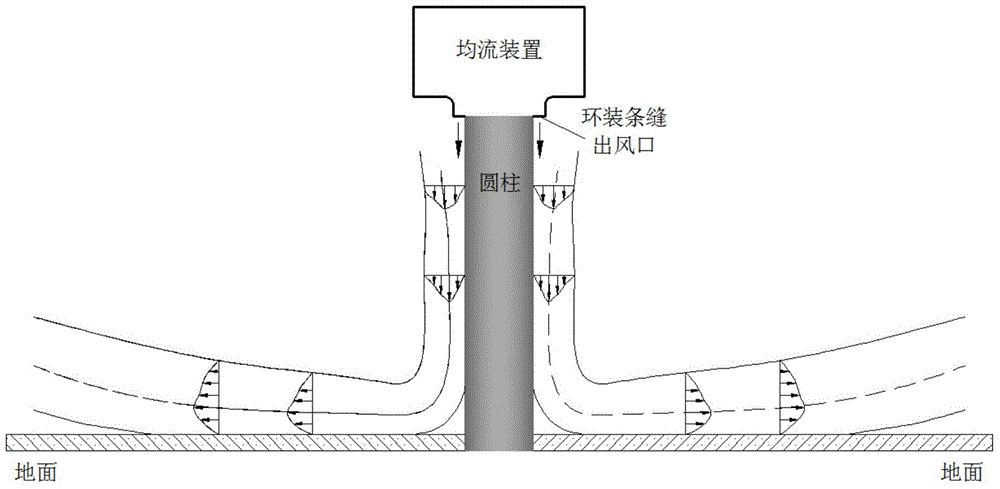

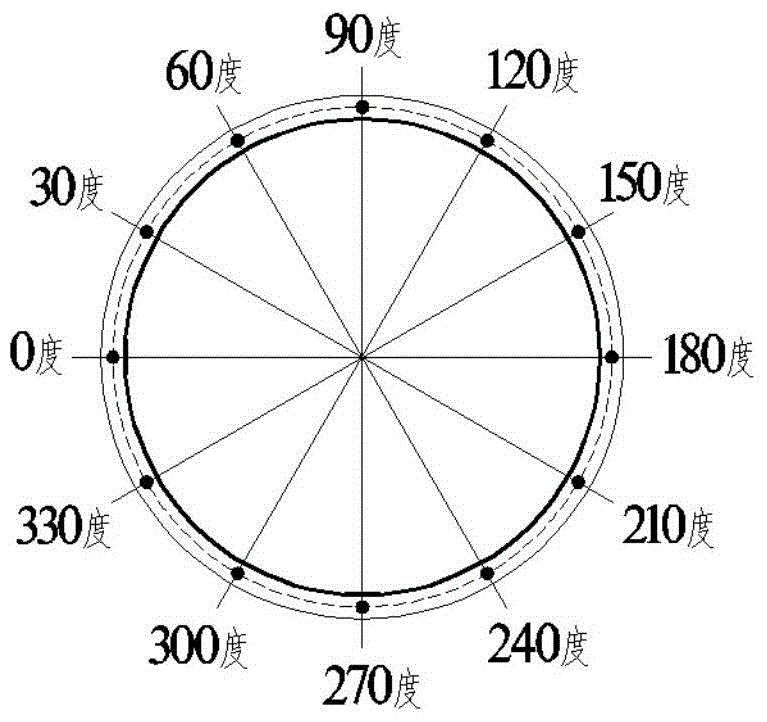

Embodiment 1

[0047] According to the actual use, the experimental model of the annular equal-section flow equalization device is established, and the cylinder with a diameter of 1000mm is used as the application object. The diameter of the shell 3 is 1700mm, and the total height is 1080mm (the height of the uppermost annular air duct is 300mm, and 6 annular partitions 9 The heights of the 5 separated flow areas are all 100mm, the height of the flow equalization area between the annular orifice plate 8 and the adjacent annular partition plate 9 is 100mm, the height of the air outlet area is 100mm, and the height of the diversion section is 80mm, a total of 1080mm); The width of the upper annular partition is 200mm, and it is installed horizontally along the bottom surface of the annular air duct of the flow equalization device. The width of the remaining five annular partitions 9 is 250mm, and they are installed horizontally at equal intervals of 100mm from the uppermost annular partition; th...

Embodiment 2

[0055] Others are the same as in Embodiment 1, and the number of annular partitions is 4 (corresponding to the total height of the housing of the flow equalizing device of 880 mm). When the design air supply speed is 1.0, 1.5 and 2.0m / s respectively, when using the flow equalization device of the present invention, the maximum difference between the speed of the 12 measuring points and the design value is 10.0%, 12.7% and 16.0%, respectively, and the average deviation is 5.4% respectively , 6.8% and 8.1%; when the traditional hollow shell static pressure box device is used, the maximum difference between the speed of the 12 measuring points and the design value is 29.3%, 27.4% and 43.9%, and the average deviation is 16.5%, 15.7% and 18.9% respectively %. Compared with the latter, the wind output accuracy of the former is increased by 205.6%, 130.9% and 133.3% respectively.

[0056] In terms of the uniformity of the air outlet 4 of the annular slit air outlet, the annular equa...

Embodiment 3

[0058]Others are the same as in Embodiment 1, and the number of annular partitions is 2 (corresponding to the total height of the housing of the flow equalizer 680mm). When the design air supply speed is 1.0, 1.5 and 2.0m / s respectively, when using the flow equalizing device of the present invention, the maximum difference between the speed of the 12 measuring points and the design value is 7.0%, 10.0% and 18.5%, respectively, and the average deviation is 4.2% respectively , 5.5% and 8.4%; when the traditional hollow shell static pressure box device is used, the maximum difference between the speed of the 12 measuring points and the design value is 44.0%, 62.7% and 79.1%, and the average deviation is 20.3%, 22.2% and 27.7% %. Compared with the latter, the wind output accuracy of the former is increased by 383.3%, 303.6% and 229.8% respectively.

[0059] Regarding the air outlet uniformity of the annular slit air outlet, the annular slit air outlet unevenness is 3.9% and 5.5% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com