Totally-changeable intake and exhaust mechanism of compressed air engine and method of mechanism

A technology for compressing air, intake and exhaust, applied to engine components, variable displacement engines, machines/engines, etc., can solve the problems of high cost and complex structure, and achieve the effect of low cost and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

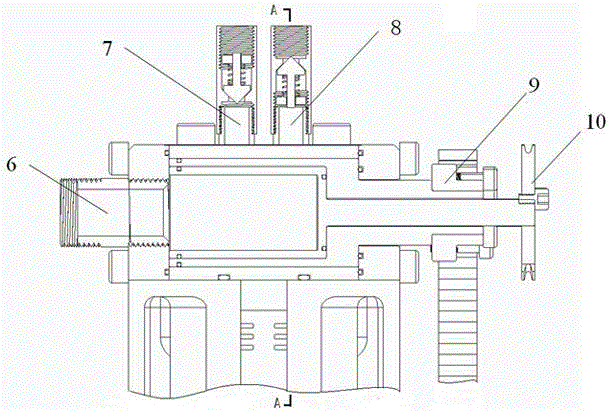

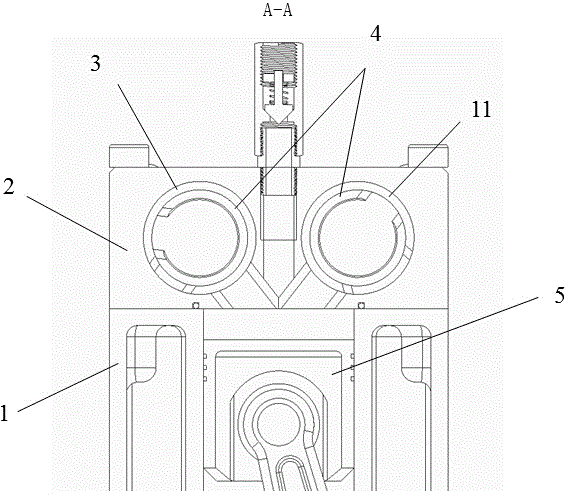

[0020] Combine below figure 1 and figure 2 This invention is introduced in detail.

[0021] A compressed air engine fully variable intake and exhaust mechanism, including cylinder wall 1, cylinder head 2, intake valve 3, exhaust valve 11, throttle valve 4, piston 5, intake and exhaust passage 6, compressed air one-way Valve 7, cylinder intake check valve 8, intake and exhaust valve power transmission mechanism 9 and throttle valve drive mechanism 10, cylinder wall 1 is provided with cylinder head 2, and cylinder head 2 is provided with intake valve 3 and exhaust valve 11. The intake valve 3 and the exhaust valve 11 are connected to the gas storage tank through the intake and exhaust passage 6. The inner layer of the intake valve 3 and the exhaust valve 11 is covered with a throttle valve 4, and the throttle valve 4 is controlled by the throttle valve. The drive mechanism 10 is driven, the intake valve 3 and the exhaust valve 11 are driven by the intake and exhaust valve pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com