Underground coal mine coal seam drilling high-pressure gas fracturing and permeability increasing method and system

A technology of high-pressure gas and coal mines, which is applied in the field of high-pressure gas fracturing anti-permeability methods and systems for underground coal seam drilling in coal mines. It can solve the problems of small effective drilling range, sealing problems, and heavy workload, and achieve intrinsic safety. Resilience, Enhanced Fracture and Connectivity, Ease of Access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

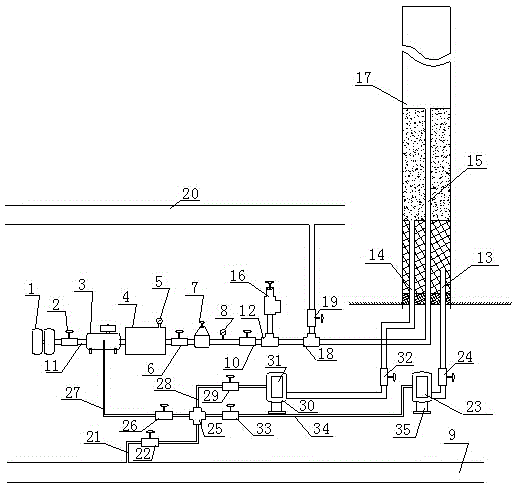

[0015] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] figure 1 As shown, it consists of gas injection system, liquid injection system, grouting system and compressed air system; the gas injection system consists of nitrogen generator 1, first valve 2, pneumatic booster pump 3, gas collection tank 4, first The pressure gauge 5, the second valve 6, the pressure reducing valve 7, the second pressure gauge 8, the third valve 10, the first three-way pipe 12, and the second three-way pipe 18 are sequentially connected through the gas injection pipeline 11 and connected with the fracturing pump. The extraction pipe 15 is connected; the fracturing extraction pipe 15 is passed into the coal seam borehole 17;

[0017] Wherein: a connecting end of the first three-way pipe 12 is connected to the back pressure valve 16 through a pipeline; the first pressure gauge 5 is installed on the gas collecting tank 4; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com