Automatic sizing trowel

A trowel and automatic technology, applied in construction, building construction, etc., can solve problems such as low labor efficiency, easy fatigue of the arms, and lumbar muscle strain, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

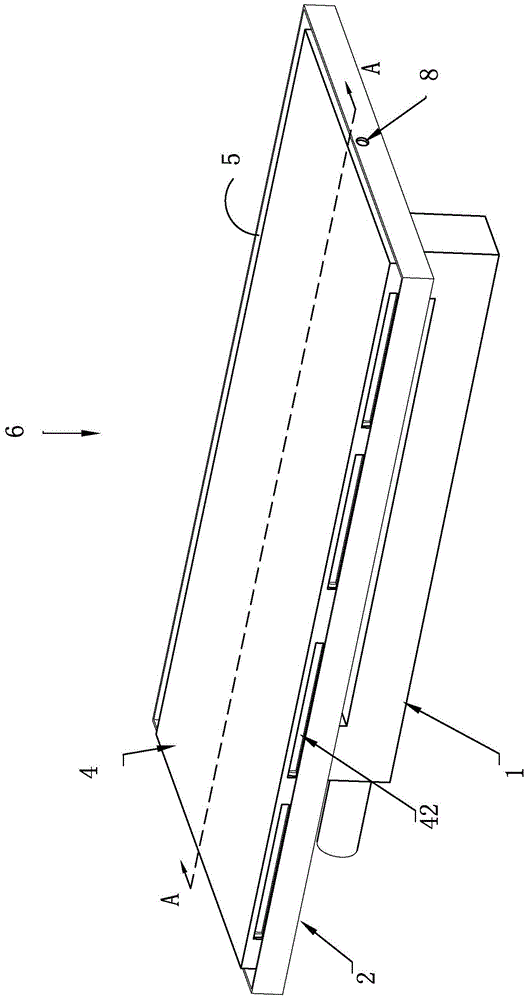

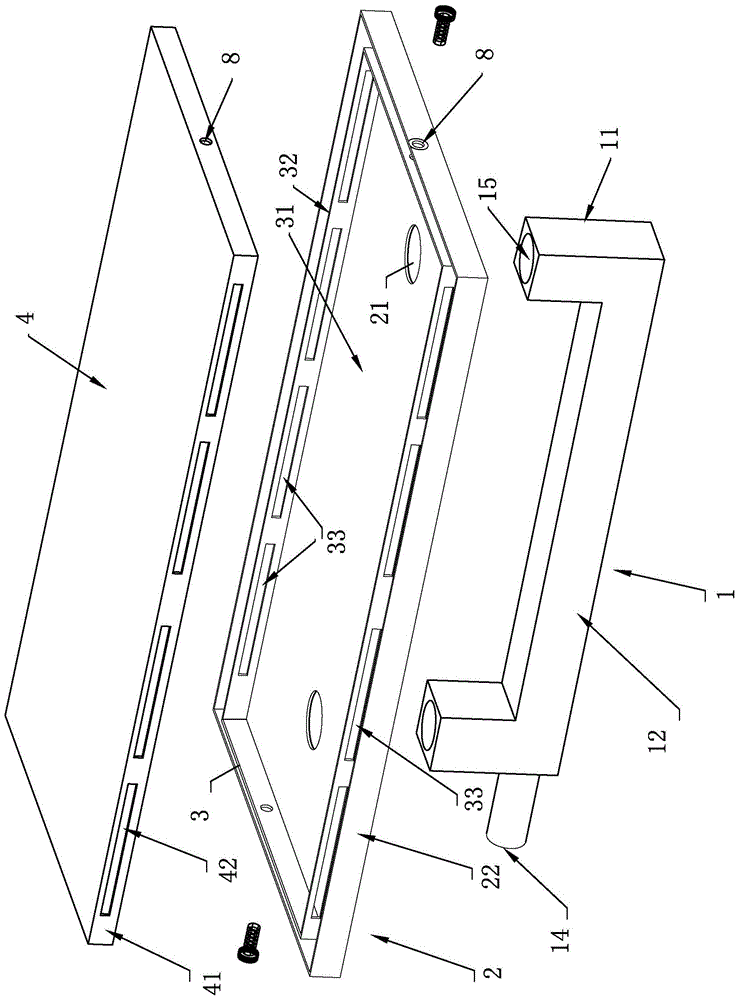

[0026] Such as figure 1 , 2 , Shown in 3, automatic sizing trowel 6 of the present invention is made of handle 1, trowel box assembly and wiper plate 4.

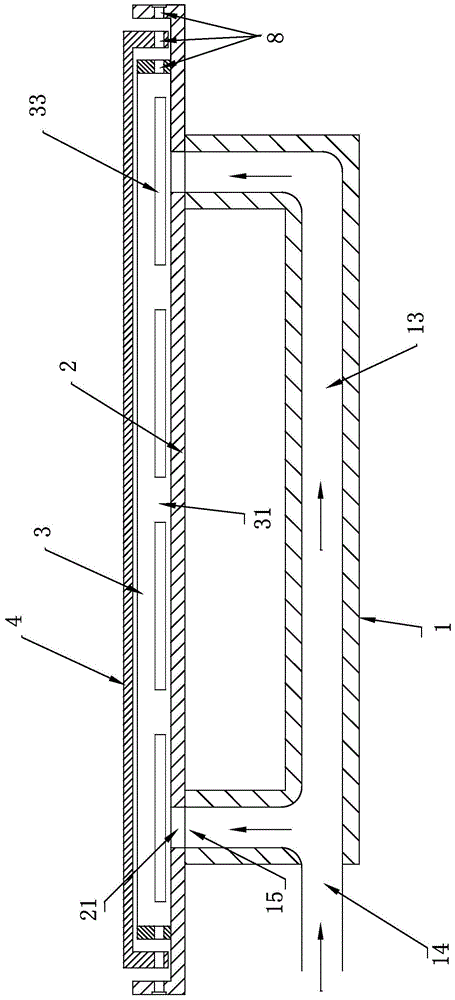

[0027] The handle 1 is composed of two handle posts 11 and a handle 12 connected between the two handle posts 11, and a slurry conveying channel passing through the handle post 11 and the handle 12 is built in the handle post 11 and the handle 12 13. The slurry inlet 14 of the slurry delivery channel 13 is set at the rear end of one of the columns 11 (the direction of the wiper 4 is the front, the direction of the handle 12 of the handle 1 is the rear, the same below), and the slurry inlet 14 passes through The delivery pipe provided outside is connected with the slurry feeding device 7 .

[0028] Two slurry outlets 15 of the slurry delivery channel 13 are respectively arranged on the front faces of the two handlebars 11 .

[0029] The handle 1 is fixed together with the box body 2 in the trowel box assembly in such a way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com