Compound motion deviation correcting device use for belt conveyor

A belt conveyor and compound motion technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of unstable swing of the swing roller frame, large rotation resistance at the middle hinge, and inflexible movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

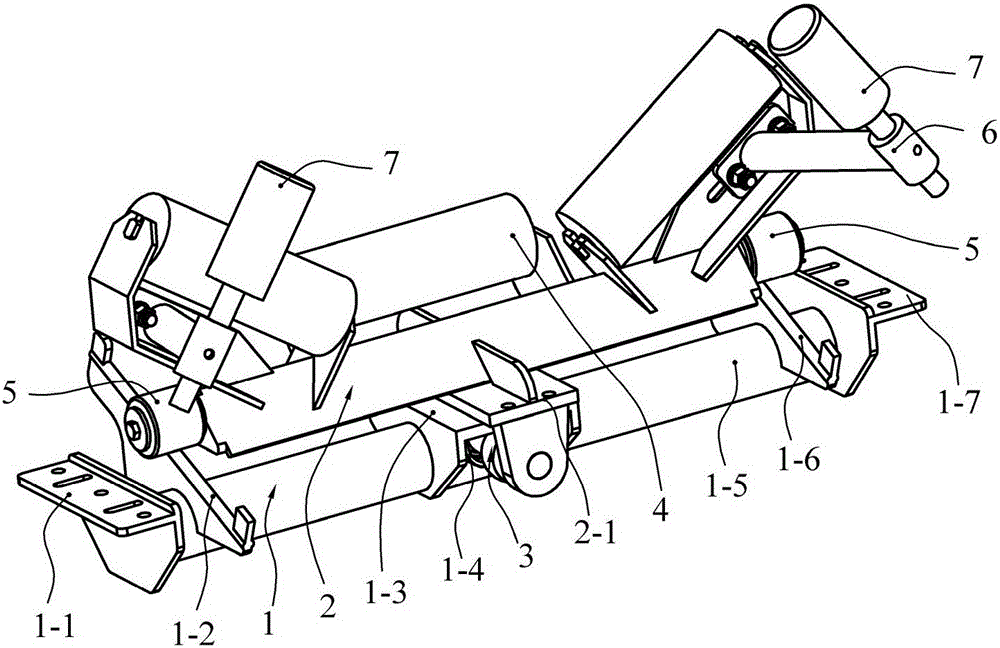

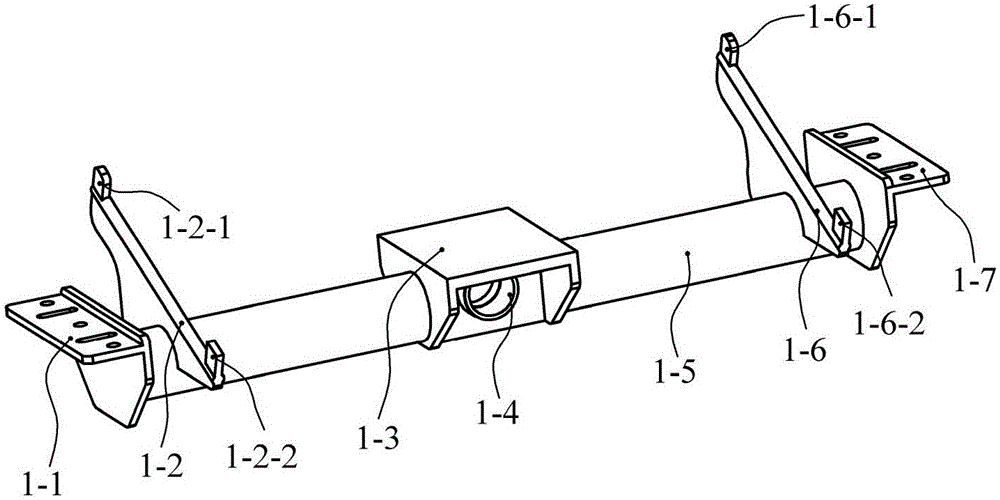

[0026] Refer to attached figure 1 , 2 , 3, 5, 6, 7

[0027] The technical solution adopted by the present invention to solve its technical problems is:

[0028] Such as figure 1 As shown, the first embodiment of the compound motion correction device for belt conveyors includes a bottom beam 1, a swing idler frame 2, an idler roller 4, a guide roller frame 6, and a guide roller 7, and the idler roller 4 is clamped on the swing idler roller On the frame 2, the guide rollers 7 are symmetrically installed on both ends of one side of the swing roller frame 2 through the guide roller frame 6. The bottom crossbeam 1 is a horizontally symmetrical structure, and the two ends of the bottom crossbeam 1 are symmetrically provided with longitudinal inclined guide rails one 1-2 and inclined guide rail two 1-6. In the first embodiment, inclined guide rail one 1-2 and inclined guide rail two 1 -6 is symmetrically arranged on the crossbeam 1-5, the middle part of the bottom crossbeam 1 is ...

Embodiment 2

[0040] Refer to attached Figure 4

[0041] The structure of the swing idler frame 2 in the second embodiment is the same as that in the first embodiment, and the horizontal support shaft assembly 3 is also connected with the bottom connection plate 2-1 of the swing idler frame 2 through the shaft end connector 3-1, and the characteristic is that : the middle part of the bottom beam 1 is provided with a spherical hinge seat 1-4 connected with the bottom beam 1 through a screw 3-10; Journal 1 3-7 and journal 2 3-13; the inner spherical outer ring 3-12 cooperates with the middle sphere 3-11 of the horizontal support shaft 3-2 to form a ball pair; the inner spherical outer ring 3-12 is placed on the ball joint In the seat 1-4, and in the ball hinge seat 1-4, it is axially positioned by the positioning notch 1-4-2 and the retaining ring 1-4-1 for the hole; the two side rollers 3-4 are provided with bearings 3-9, respectively worn on the journal one 3-7 and journal two 3-13 of th...

Embodiment 3

[0044] Refer to attached Figure 8 :

[0045] Figure 8 The third embodiment of the present invention is a compound motion correction device for the return conveyor belt of the belt conveyor. The structure of embodiment three and figure 1 The structure of the deviation correcting device for the carrier belt shown is similar, and the third embodiment is connected to the middle frame of the belt conveyor through the side mounting frame 10 .

[0046] Utilizing the present invention, both the deviation correcting device for the carrying conveyor belt of the belt conveyor and the deviation correcting device for the return conveyor belt can be designed. The present invention realizes the dual-motion combination of the horizontal swing and the swing in the vertical plane of the swing idler group, and utilizes the space swing within a certain range to rectify the conveyor belt of the belt conveyor, which can achieve a good rectification effect. It can be used in belt conveyors in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com