A method for repairing heavy metal polluted soil by pressure filtration and leaching

A technology for polluted soil and heavy metals, applied in the field of environmental remediation, can solve the problems of excessive heavy metal indexes and excessive heavy metal indexes of soil leaching toxicity, and achieve the effects of increasing the reaction concentration and reducing the amount of eluent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

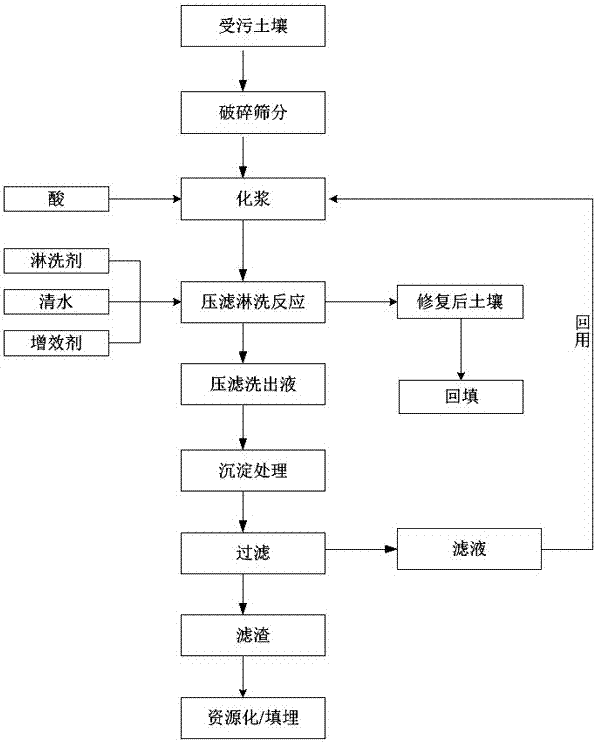

Image

Examples

Embodiment 1

[0029] A method for repairing heavy metal-contaminated soil by pressure filtration and leaching, comprising the following steps:

[0030] (1) Crushing and screening: Based on the soil of a Pb-contaminated waste site, the total Pb concentration is 3.075 mg / g, the contaminated soil is sent to the crusher for crushing, and then enters the screening system for two-stage screening. Separation of impurities and large-grained stones in the soil to obtain 300kg of sieved soil;

[0031] (2) Slurry reaction: Slurry the sieved soil at a solid-to-liquid ratio of 1:4, and stir and react with 0.7mol / L hydrochloric acid for 30 minutes to fully react the acid-soluble heavy metals in the soil;

[0032] (3) Press filter leaching: put the fully reacted slurry into the filter press reactor for filtration, then pump 350L of clear water into the filter press reactor, and let the clear water wash away the remaining residue in the capillary pores of the soil filter cake. The acid solution is replace...

Embodiment 2

[0036] A method for repairing heavy metal-contaminated soil by pressure filtration and leaching, comprising the following steps:

[0037] (1) Crushing and screening: Based on the soil of a Pb-contaminated waste site, the total Pb concentration is 3.075 mg / g, the contaminated soil is sent to the crusher for crushing, and then enters the screening system for two-stage screening. Separating the impurities and large-grained stones in the soil to obtain 250kg of sieved soil;

[0038](2) Slurry reaction: Slurry the sieved soil at a solid-to-liquid ratio of 1:3, and stir and react with 1mol / L hydrochloric acid for 30 minutes to fully react the acid-soluble heavy metals in the soil;

[0039] (3) Press filter leaching: put the fully reacted slurry into the filter press reactor for filtration, then pump 750L of clear water into the filter press reactor, and let the clear water wash away the remaining residue in the capillary pores of the soil filter cake. The acid solution is replaced ...

Embodiment 3

[0043] A method for repairing heavy metal-contaminated soil by pressure filtration and leaching, comprising the following steps:

[0044] (1) Crushing and screening: Based on the soil of a Pb-contaminated waste site, the total Pb concentration is 3.075 mg / g, the contaminated soil is sent to the crusher for crushing, and then enters the screening system for two-stage screening. Separation of impurities and large-grained stones in the soil to obtain 400kg of sieved soil;

[0045] (2) Slurry reaction: Slurry the sieved soil at a solid-to-liquid ratio of 1:5, and stir and react with 0.1mol / L hydrochloric acid for 30 minutes to fully react the acid-soluble heavy metals in the soil;

[0046] (3) Press filter leaching: put the fully reacted slurry into the filter press reactor for filtration, then pump 400L of clear water into the filter press reactor, and let the clear water wash away the remaining residue in the capillary pores of the soil filter cake. The acid solution is replace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com