Processing equipment and processing technology

A technology for handling and processing boards, used in wood processing appliances, manufacturing tools, special forming/shaping machines, etc., can solve the problems of poor processing effect and slow efficiency, reduce labor requirements, easy to use, and simplify the process. The effect of edge processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

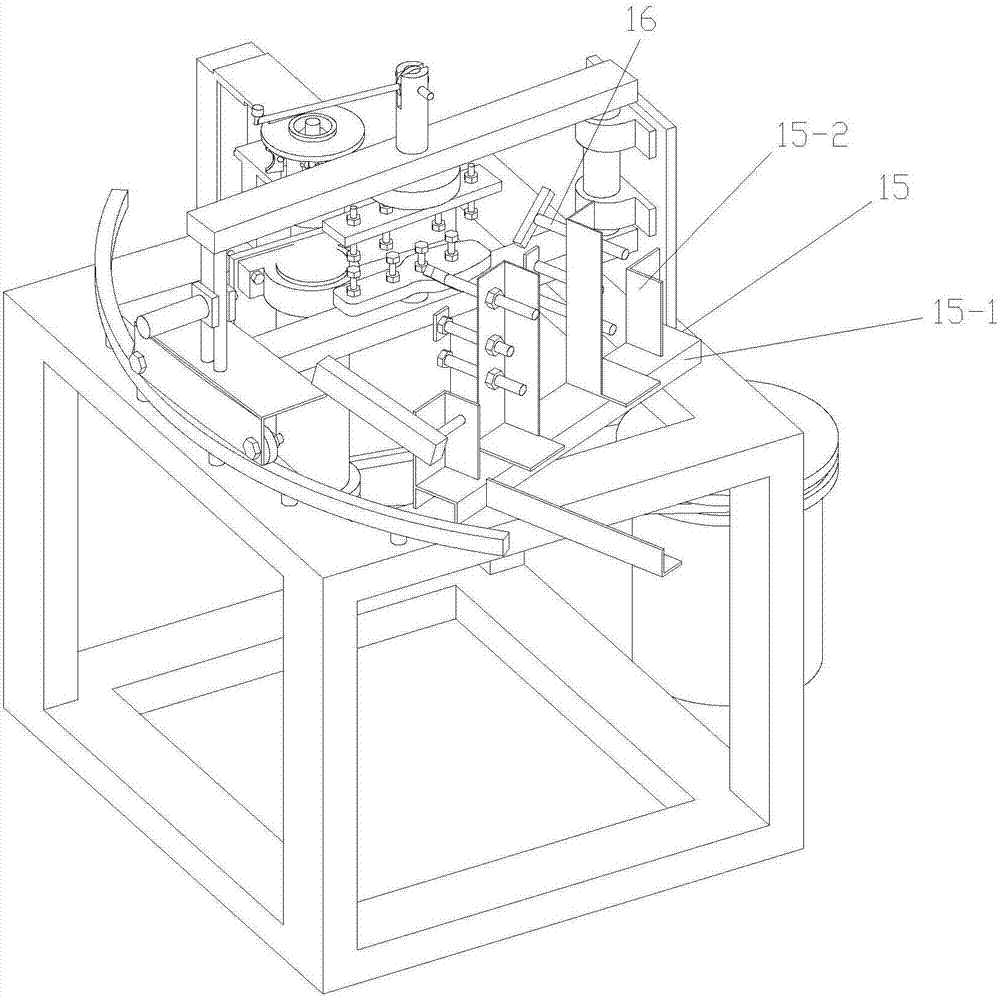

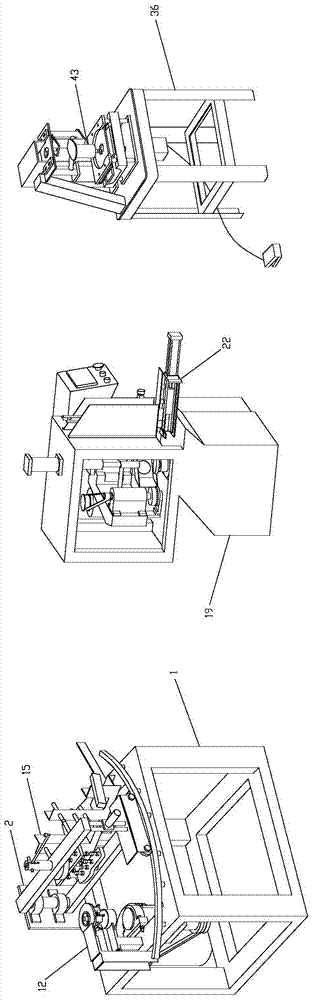

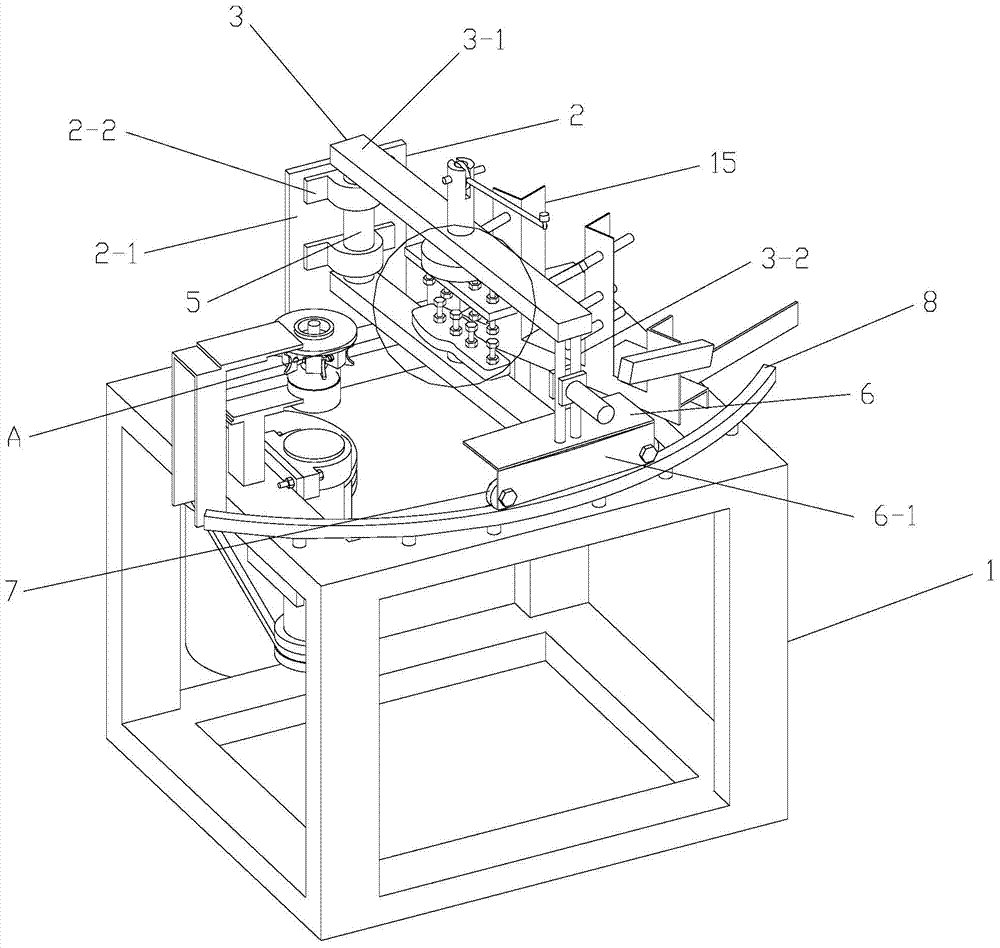

[0036] The present invention will be further described below in conjunction with accompanying drawing:

[0037] The steps of this processing method for the handle of the brush are as follows:

[0038] (1) Put the blank body to be processed into the edge removal machine, and fix it in by clamping;

[0039] (2) Start the edge removing machine, and remove the remaining edge of the blank body through the edge removing machine, so that the blank body is formed into a brush handle by processing;

[0040] (3) Put the trimmed part of the brush brush into the profiling machine, and fix it in by clamping;

[0041] (4) Start the profiling machine, and the processing tool on the profiling machine performs groove processing on the handle of the brush according to the preset movement track of the profiling machine.

[0042] (5) Manually install the bristle installation part and the bristles into the handle of the scrub brush to make it a complete scrub brush, and perform chip removal and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com