Integral PSS etching tray fixture

An integral, tray technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as changes in equipment hardware structure, the cost and workload of transformation, and improve work efficiency, easy operation, and edge effects. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

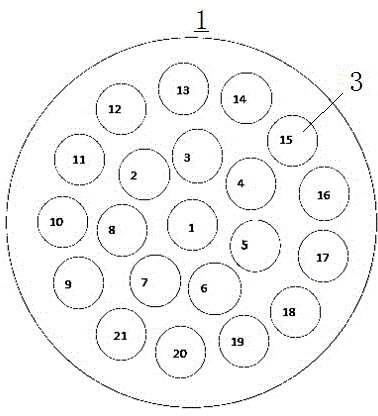

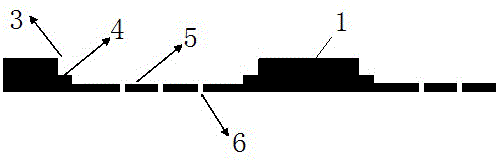

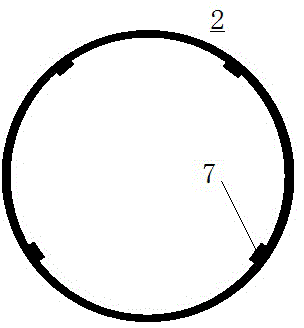

[0024] See attached figure 1 to attach Figure 4 as shown, figure 1 Described the front view of the integrated tray of the integrated PSS etching tray jig according to the present invention, figure 2 A partial cross-sectional view of the integral tray of the integral PSS etching tray jig according to the present invention is described, image 3 The front view of the pressure ring of the integrated PSS etching tray fixture according to the present invention is described, Figure 4 A partial cross-sectional view of the pressure ring of the integrated PSS etching tray jig according to the present invention is described.

[0025] The integrated PSS etching tray jig of the present invention comprises an integral tray 1 and a pressure ring 2 made of a metal material, and the material of the integral tray 1 is not limited (it can be quartz, metal, or ceramics), but the monolithic tray 1 must be a monolithic structure.

[0026] In order to ensure that wafers can be placed, it is...

Embodiment 2

[0031] See attached Figure 5 as shown, Figure 5 A front view of the pressure ring of the integral PSS etching tray jig in another embodiment is described. The pressure ring in this embodiment is generally similar to the structure of the pressure ring in Embodiment 1. The difference is that the actual wafer is often not absolutely circular, but has a positioning edge. Therefore, the corresponding slot 3 Both the pressure ring 2 and the pressure ring 2 need to design the positioning edge 8.

[0032] In addition, according to the design accuracy and the effect in actual use, the inner diameter of the slot 3 can be selected for placing the sealing ring, so as to enhance the sealing performance of the side part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com