Electronic monitor for content of fault gas in transformer gas relay

A gas relay and fault gas technology, applied in the field of transformers, can solve the problems of serious faults, wrong transmission, inability to realize computer communication, etc., and achieve the effects of strong anti-interference ability, convenient centralized monitoring and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

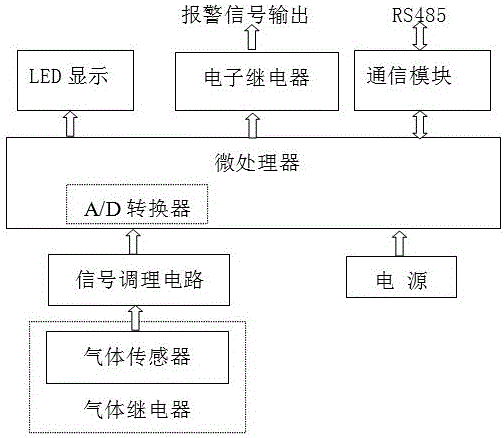

[0014] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a gas relay, a gas sensor is arranged inside the gas relay, the gas sensor is connected to a microprocessor, and the microprocessor is connected to a contact for outputting an alarm signal through an electronic relay. The microprocessor is connected to the RS485 communication interface through the communication system. The gas sensor is connected with the A / D converter of the microprocessor through a signal conditioning circuit. The microprocessor is connected with an LED display panel. The microprocessor is connected to power.

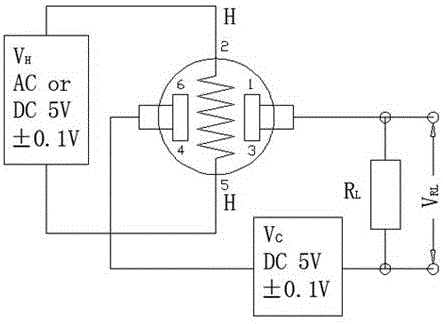

[0015] The electronic monitor for fault gas content in a transformer gas relay of the present invention adopts a carrier catalytic element as a gas detection element, that is, a gas sensor, to generate a weak analog voltage signal proportional to the transformer fault gas (gas) content, and after signal conditioning After the circuit is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com