A cross-beam two-dimensional micro-force measuring device based on psd

A measuring device and cross technology, applied in the direction of measuring device, measuring force, optical device, etc., can solve the problems that are not suitable for large-scale promotion, complex structure, high cost, etc., and achieve the reduction of external influence, good coherence, and collimation good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

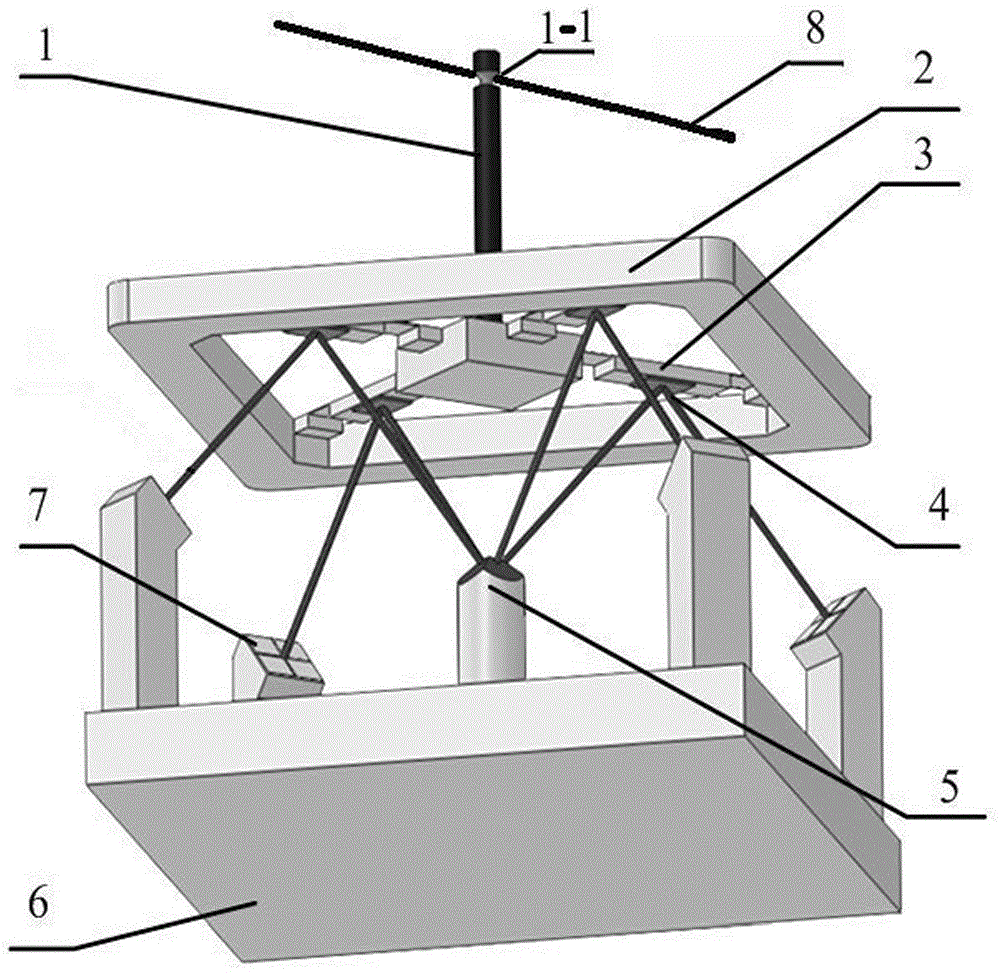

[0014] Specific implementation mode one: combine figure 1 As shown, it includes a measuring rod 1, a square measuring rod support 2, a cross beam 3, four mirrors 4, a quarter semiconductor laser 5, a base 6, and four two-dimensional PSD position sensors 7;

[0015] There is a ring groove 1-1 on the outer surface of the upper part of the measuring rod 1 for clamping with the measured hairspring 8; the lower end of the measuring rod 1 is vertically connected with the upper end surface of the center of the cross beam 3, and the cross beam 3 is arranged in a square frame for measuring Inside the rod support 2, the outer ends of the four beams of the cross beam 3 are respectively connected with the four corners of the square measuring rod support 2, and the four reflectors 4 are arranged under the four beams of the cross beam 3 respectively. On the end face, the reflective surfaces of the four reflective mirrors 4 are all facing downward; the quarter semiconductor laser 5 is arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com