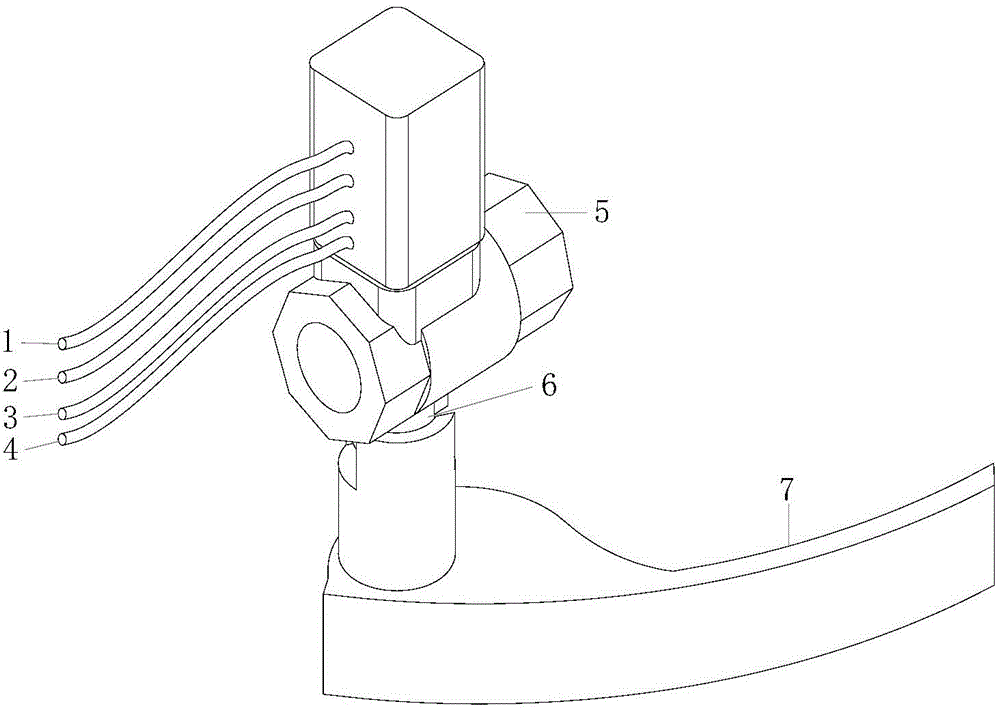

Air inlet and ignition integrated valve for commercial gas stove

A gas stove, commercial technology, used in household stoves/stoves, applications, valve details, etc., can solve problems such as inconvenient operation and hidden safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

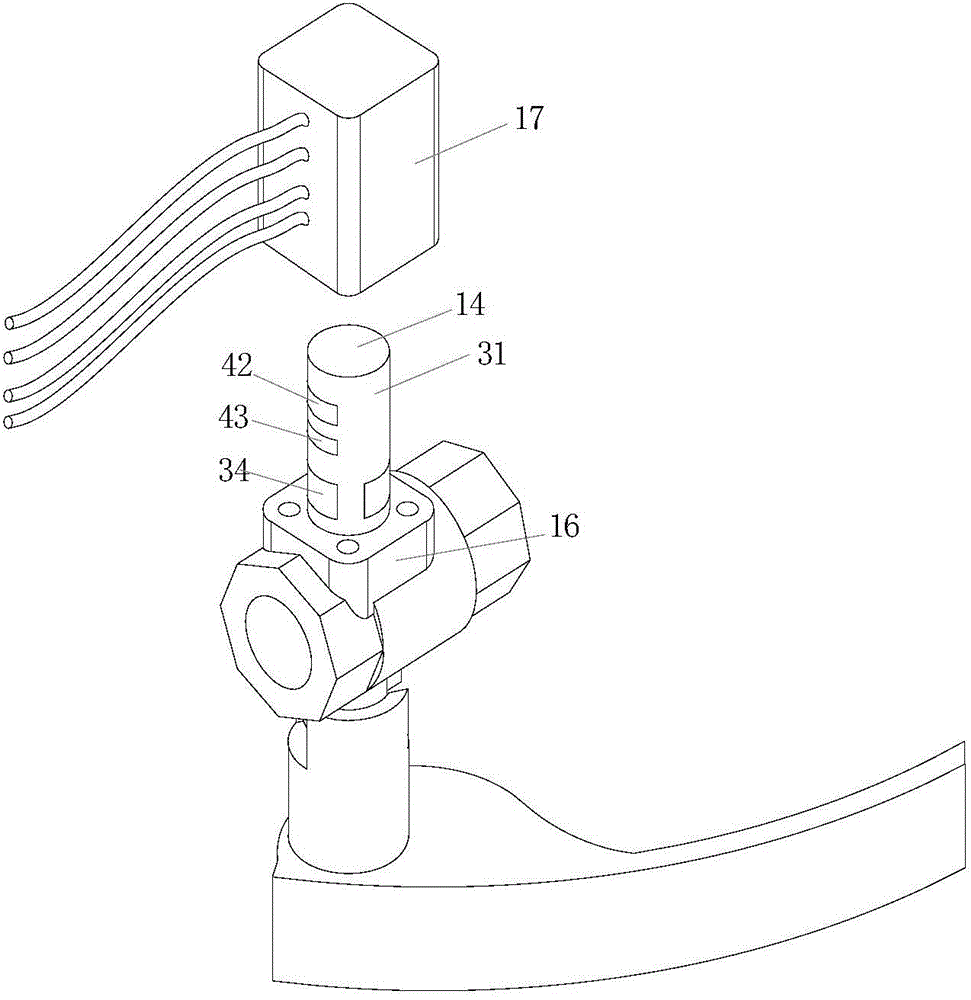

[0034] The switch is turned on when the valve is closed, and the switch is closed when the valve is opened. The principle is as follows: Figure 6 As shown, when the valve is closed, the rotation angle of the valve stem is in the 0 state, and at this time the conductive contacts 32, 33 are all on the first conductor slip ring segment 34, and the two ends of the conductive contacts 32, 33 are connected, that is to control the open state of the switch.

[0035] When the valve stem rotation angle is greater than 0° during the valve opening process, such as Figure 7 As shown, at this time, the conductive contacts 32, 33 are on the insulator 31, and the two points of the contacts 32, 33 are not conducting. At this time, the control switch is in the closed state.

Embodiment 2

[0037] When the valve is not fully open, the control switch is closed; when the valve is fully open at 90°, the control switch is open, the principle is as follows Figure 8 shown. When the valve is not fully opened, the conductive contacts 32, 33 are on the insulator 31, and the two points of the contacts 32, 33 are not conducting, which is the closed state of the control switch.

[0038] When the stem rotation angle is 90°, such as Figure 9 As shown, the valve is opened in the fully open state. At this time, the conductive contacts 32, 33 are all on the first conductor slip ring segment 34. At this time, the two ends of the conductive contacts 32, 33 are connected, which is the open state of the control switch.

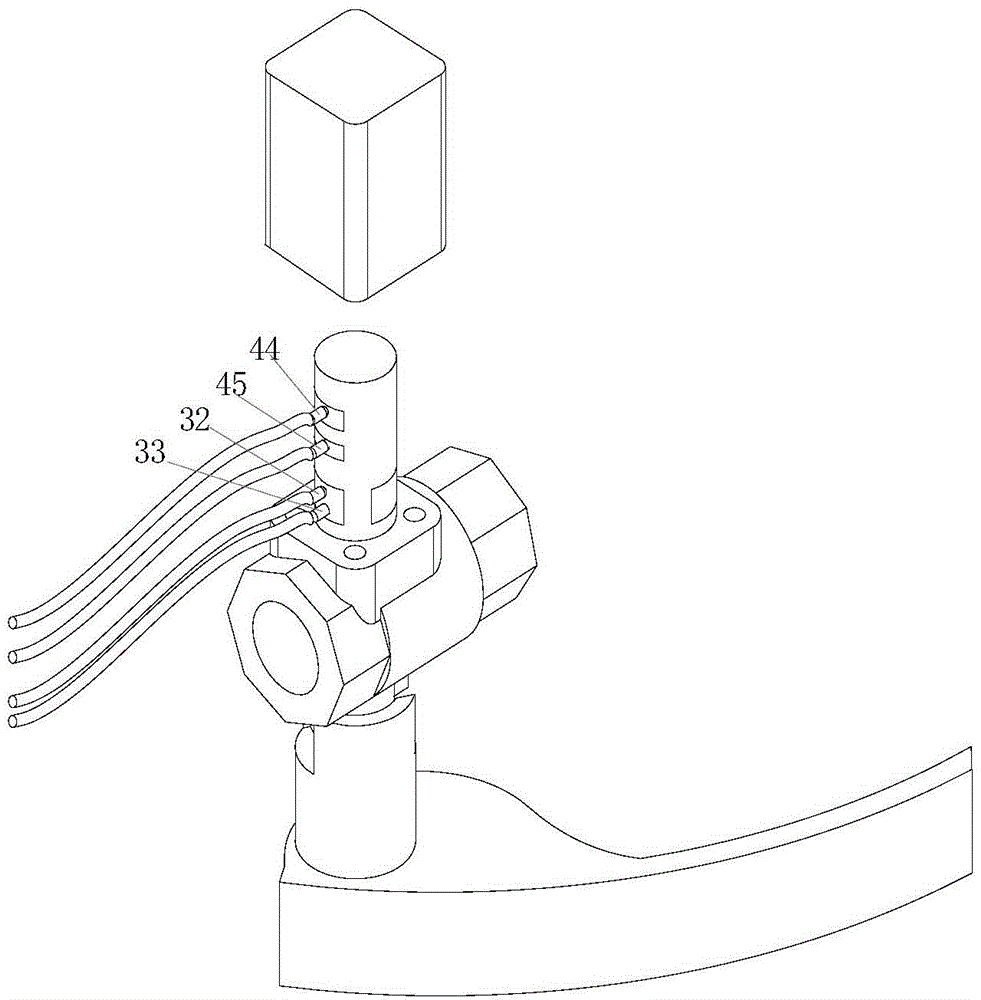

[0039] 3. The principle of the potentiometer switch is as follows:

[0040] Such as Figure 10As shown, when the valve is closed, the rotation angle of the valve stem is 0°, the conductive contacts 44, 45 are on the insulator 41 outside the second conductive rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com