Preparation Method of Automobile Coatings Based on Orthogonal Design

An orthogonal design and coating technology, which is applied in the application of automotive coatings and the preparation of automotive coatings, can solve the problems of increasing the complexity of construction and application, uneven and dull coating surface, and poor alkali resistance of coatings. Effects of improving spraying quality, reducing product quality fluctuations, and reducing test times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

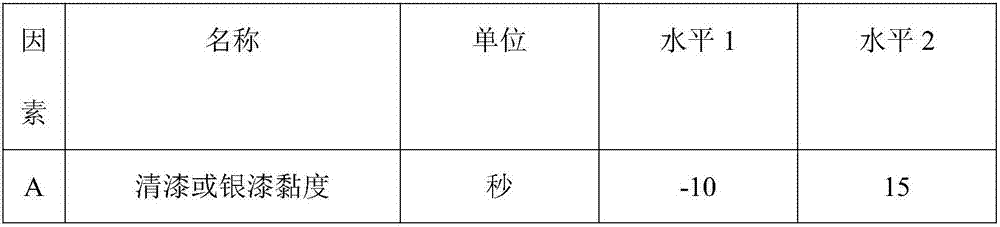

[0023] Adopt varnish to apply to automobile body steel plate, control the influencing factors in table 1 simultaneously, wherein varnish component comprises two-component polyurethane 70-72 weight parts, bismuth oxide 10-13 weight parts, fluorinated curing agent 2-5 parts , 12-16 parts of epoxy resin, 4-6 parts by weight of oxidized polyethylene.

Embodiment 2

[0025] Adopt silver paint to apply to automobile body steel plate, control the influence factor in table 1 simultaneously, wherein silver paint component comprises silver paste 0.5-1.5 weight part, epoxy resin 60-75 weight part, benzoic acid monoethanolamine 4-6 Parts by weight, 10-15 parts by weight of polyethyl acrylate.

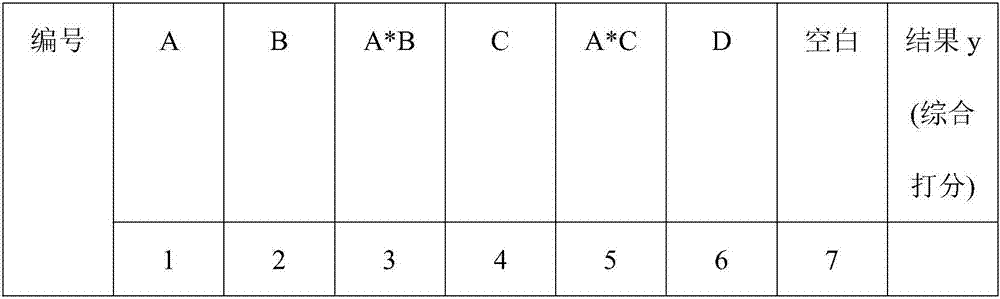

[0026] Since the paint viscosity is affected by temperature, an orthogonal design method with interaction is used. That is, A interacts with B, and A interacts with C. Establish an interactive orthogonal design table, as shown in Table 2.

[0027] Table 2 Orthogonal design results and result analysis table

[0028]

[0029]

[0030] The comprehensive score is the result of experts scoring the quality of the paint. Looking directly at the results, it can be seen that the No. 3 experiment A1B2C1D2 is the best, with a comprehensive score of 80, and the extreme difference of factor C is 8.5, the largest, indicating that factor C (that is, the constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com