Pressing device of dynamic biomass granulator

A technology of biomass particles and compacting devices, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of increased energy consumption, short bearing life, pressure wheel shaft, fatigue overload, etc., and achieve the effect of improving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

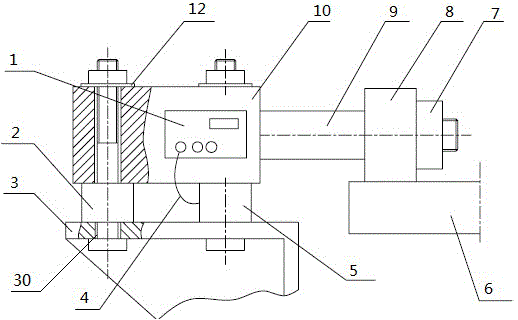

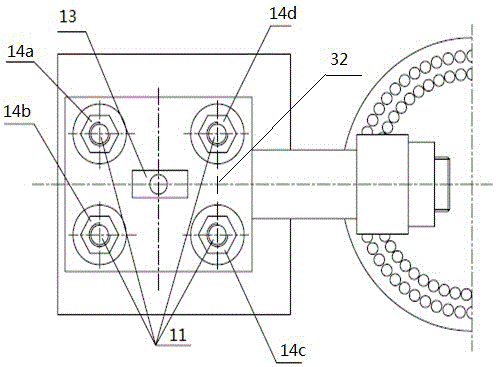

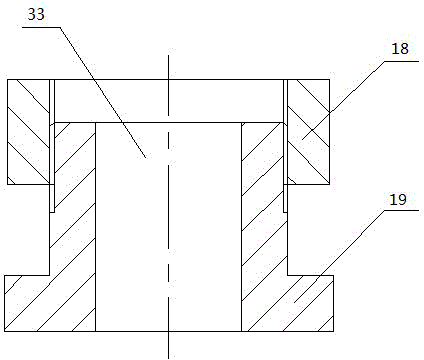

[0024] Further description will be made below in conjunction with drawings and embodiments.

[0025] Such as figure 1 , figure 2 and Figure 5 As shown, a compacting device 100 for a biomass pellet machine in dynamic mode is composed of a pressure indicator 1 , a height adjustment device 2 , a bracket 3 , a pressure measuring device 5 , a lock nut 7 , a compacting assembly 34 and a level 13 . The compression assembly 34 is made up of the pressure roller 8, the pressure roller shaft 9, the pressure roller seat 10 and the lock nut 7. One end of the pressure roller shaft 9 is installed in the center hole of the pressure roller seat 10 through a bearing, and the pressure roller shaft 9 The other end is provided with a pressure wheel 8, which is installed on the pressure roller shaft through the pressure wheel nut; the pressure roller seat 10 is fixed above the support 3, and a height adjustment device 2 is provided between the upper surface of the support 3 and the lower surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com