Insert automatic production system and its processing method

An automatic production and insert technology, which is applied in metal processing, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of mismatching production efficiency of processing equipment, unbalanced supply and demand of equipment, and high labor costs, achieving high production efficiency, Ensure the matching of supply and demand and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

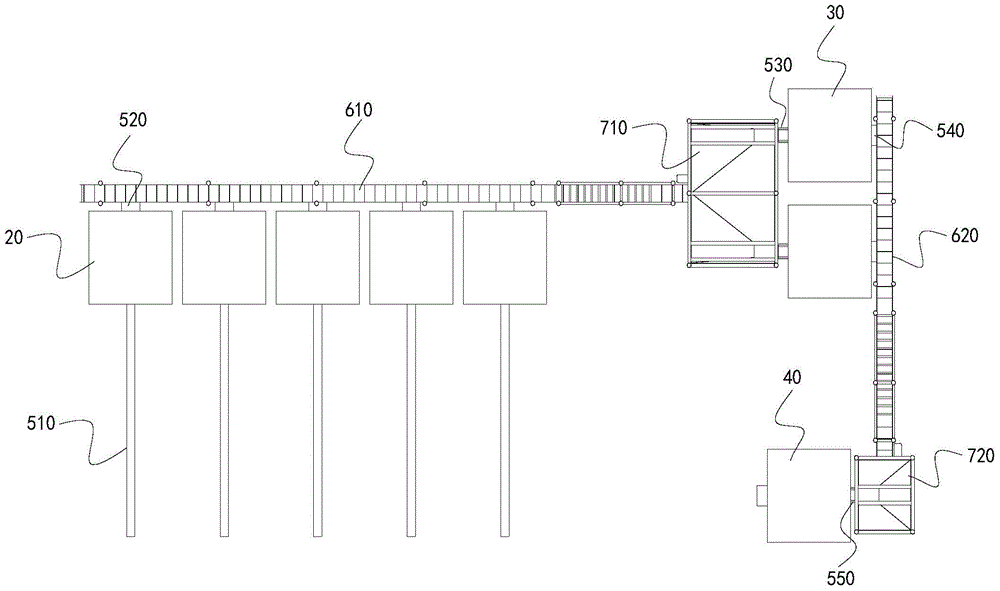

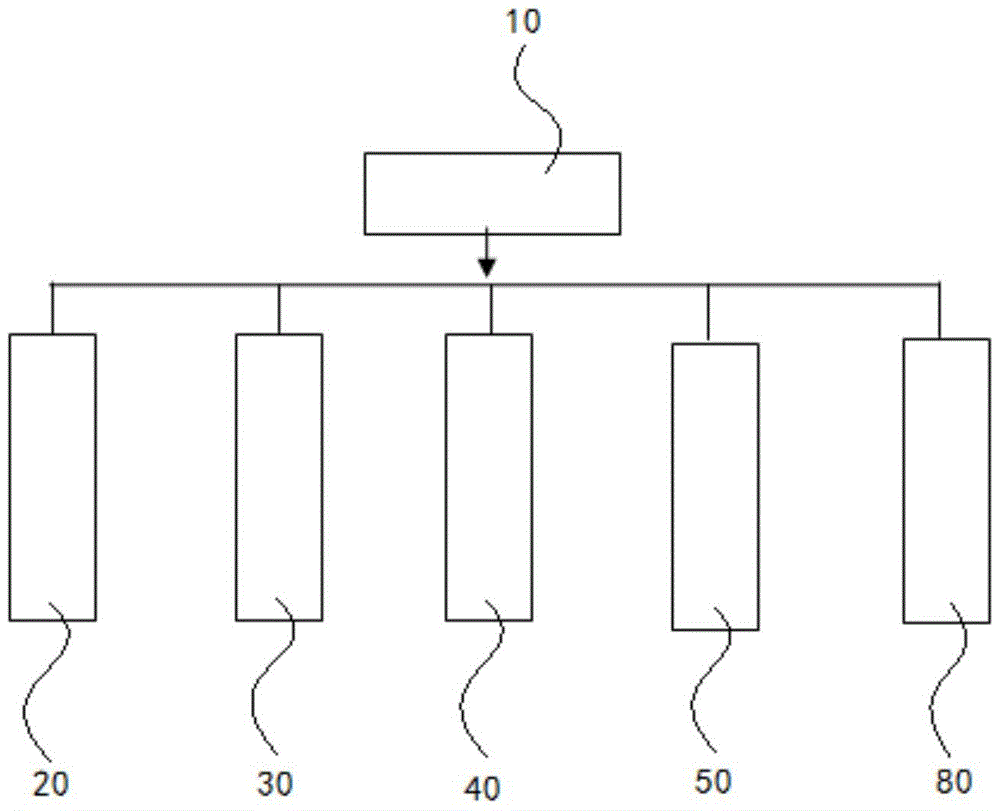

[0030] Such as figure 1 and figure 2 As shown, an automatic production system for inserts includes a controller 10, a bar material machine 20 electrically connected to the controller 10, a hydraulic press 30, a milling machine 40, a loading and unloading mechanism 50 and a conveying device, and the loading and unloading mechanism 50 Including the first loading machine 510 and the first unloading machine 520 cooperating with the bar material machine 20, the second loading machine 530 and the second unloading machine 540 cooperating with the hydraulic press 30, the third cooperating with the milling machine 40 Feeding machine 550, the conveying device includes the first conveying device 610 connected with the first unloading machine 520 and the second feeding machine 530 at both ends, and the second unloading machine 540 and the third feeding machine 550 at bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com