Horizontal cylinder assembling mechanism of hydraulic oil cylinder

A hydraulic cylinder, horizontal technology, applied in the field of hydraulic cylinder horizontal cylinder installation mechanism, can solve the problems of the difficulty in the alignment of the piston rod and the cylinder body, the inability to guarantee the central axis, and the impact on the quality of use, so as to reduce the damage on the surface of the piston rod Possibility, convenient moving and handling process, safe and reliable effect of adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

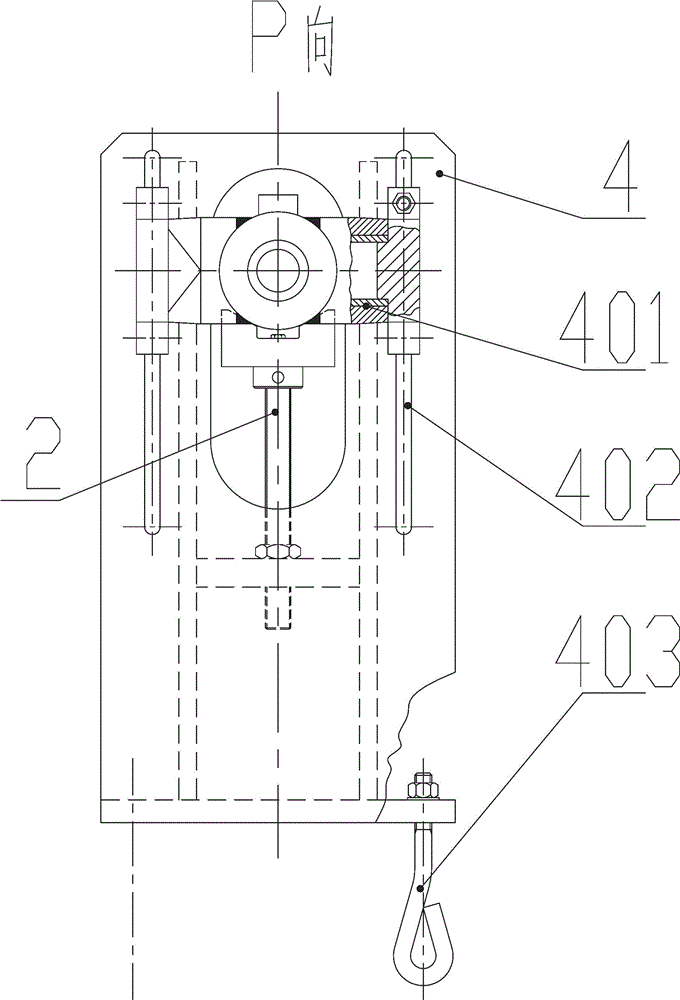

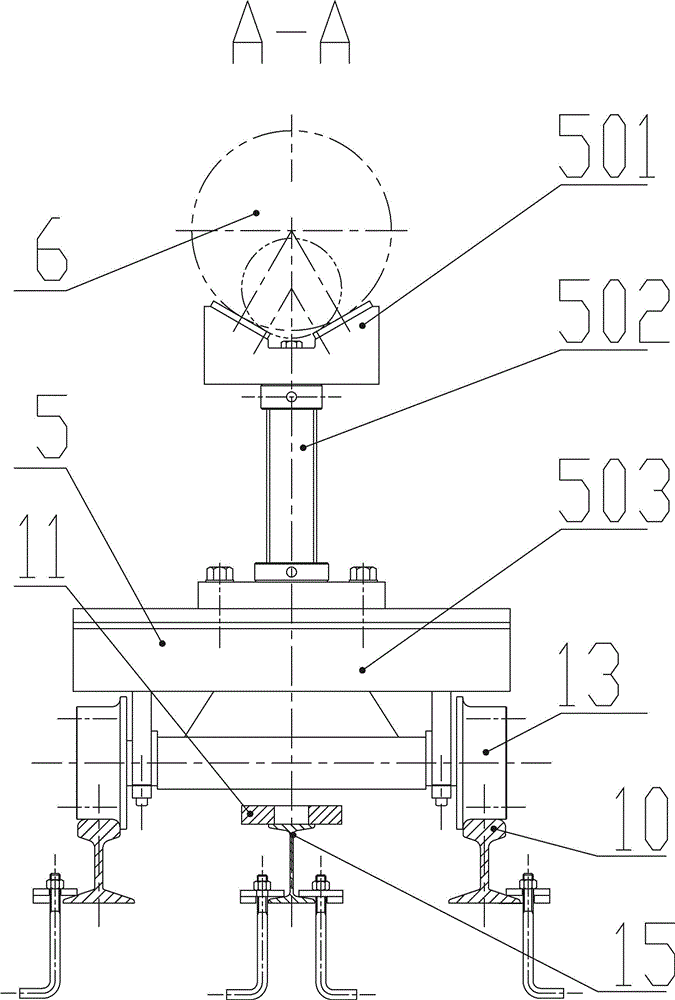

[0037] Such as Figure 1-8 As shown, a hydraulic cylinder horizontal cylinder loading mechanism, which includes a push cylinder support 4, a push cylinder 3 is installed on the push cylinder support 4, and the piston rod 6 to be assembled can be pushed through the push cylinder 3, thereby facilitating its assembly , the stability of the force in the propulsion process can be guaranteed through hydraulic control, thereby improving the accuracy of assembly. Two rails 10 are laid on the foundation 1 on the right side of the propulsion cylinder 3, and the rails 10 are fixed to the foundation 1 through a rail fixing device 12. The centering between the piston rod 6 to be assembled and the oil cylinder 8 to be assembled is ensured by setting the track 10, so as to facilitate its centering installation. The left side of the track 10 is provided with two piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com