Method for determining bonding position of a loss factor frequency-dependent unconstrained damping layer on white car body

A loss factor, body-in-white technology, applied in the field of vehicle engineering, can solve the problem of not considering the frequency change of the damping material, unable to maximize the damping and vibration reduction efficiency of the free damping layer material, etc., to achieve the effect of easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

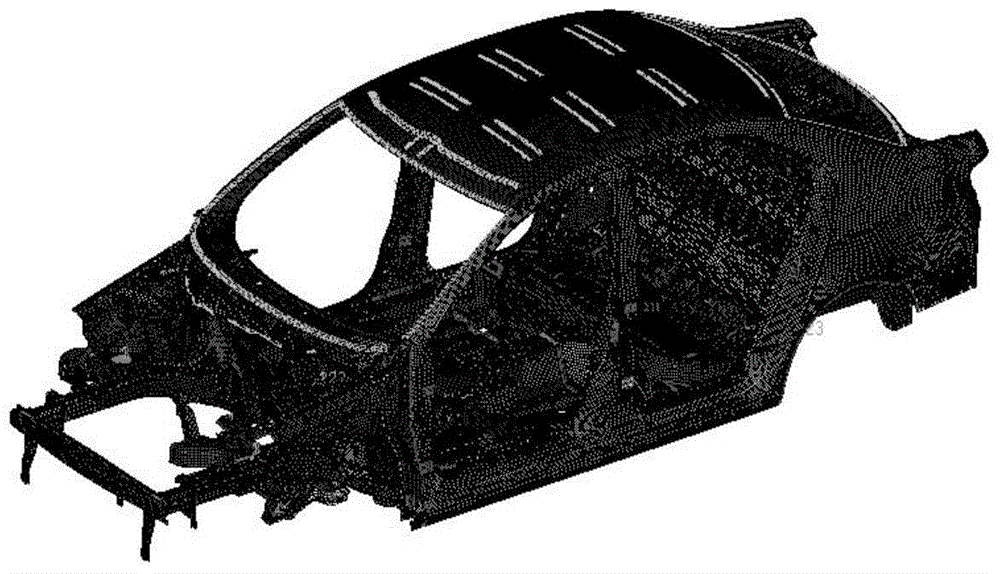

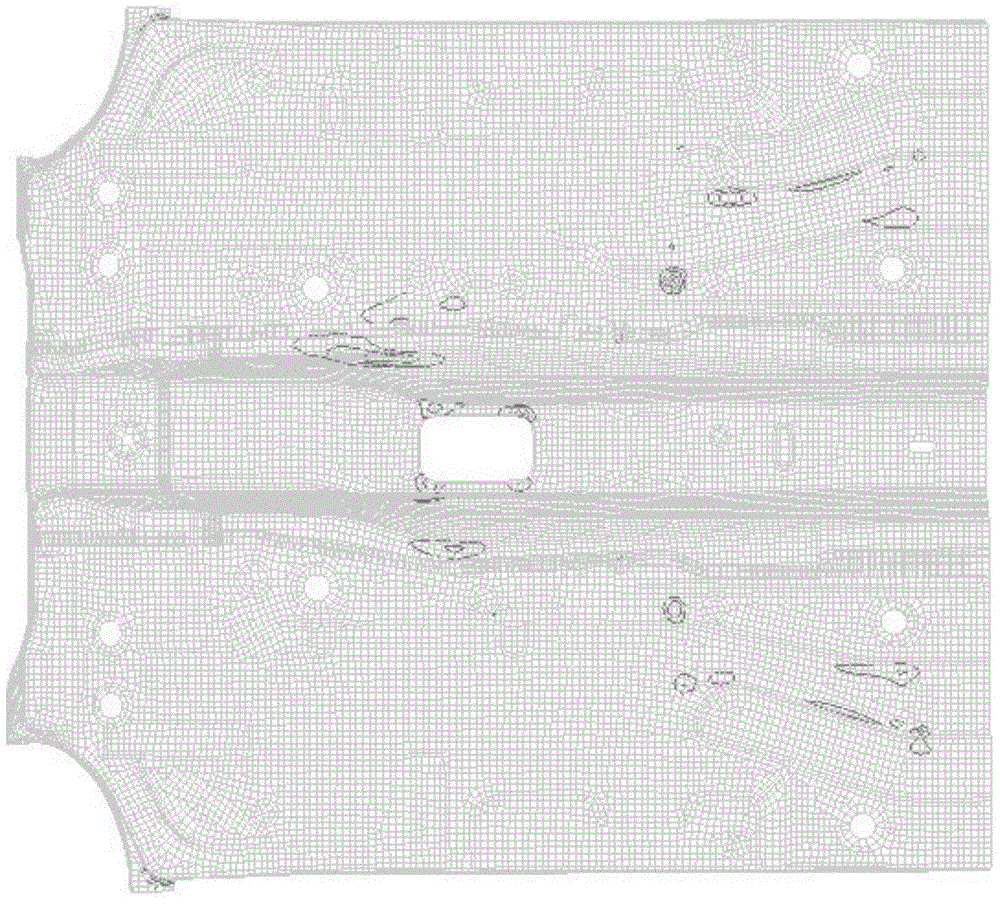

[0029] Specific implementation mode 1. Combination Figure 1 to Figure 10 Describe this embodiment, the method for determining the pasting position of the loss factor frequency-variable free damping layer on the body-in-white, this method is used to guide the arrangement position of the free damping layer of the body structure and the selection of the material type of the free damping layer. This method is based on the comprehensive modal strain energy information of the body structure. Through the finite element modeling and modal analysis of the body structure, the magnitude of the modal strain energy of each order within the frequency range where the body structure is damped and vibration-reduced can be obtained. and distribution. In this frequency range, the modal strain energy of each order of the body structure is superimposed to obtain the comprehensive modal strain energy distribution of the body structure. According to the comprehensive modal strain energy distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com