Large-view-field miniature imaging system

An imaging system and technology with a large field of view, applied in optical components, optics, instruments, etc., can solve the problems of difficult design, heavy volume and weight, and high processing cost, and achieve reduced design difficulty, compact lens structure, and reduced design. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

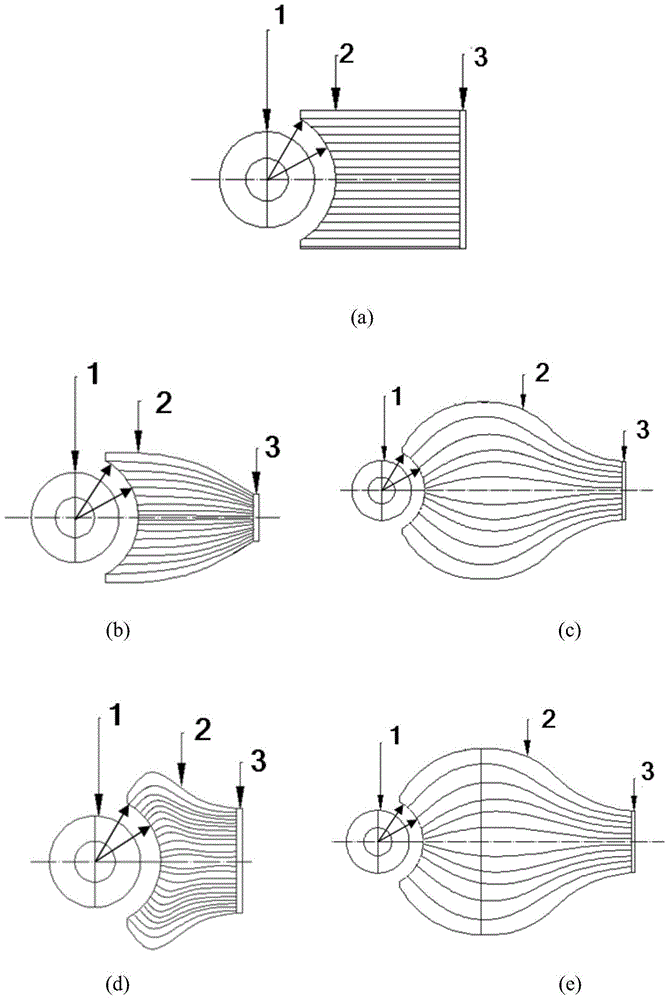

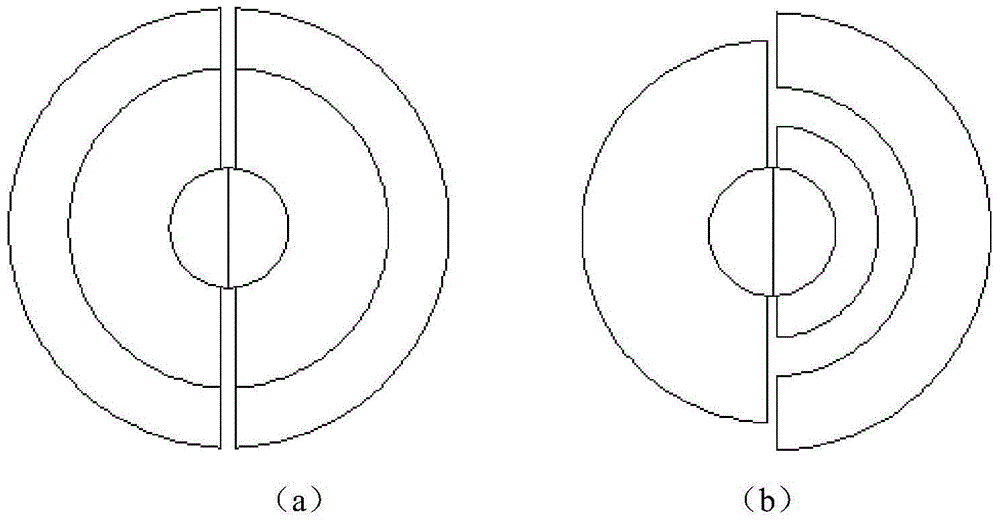

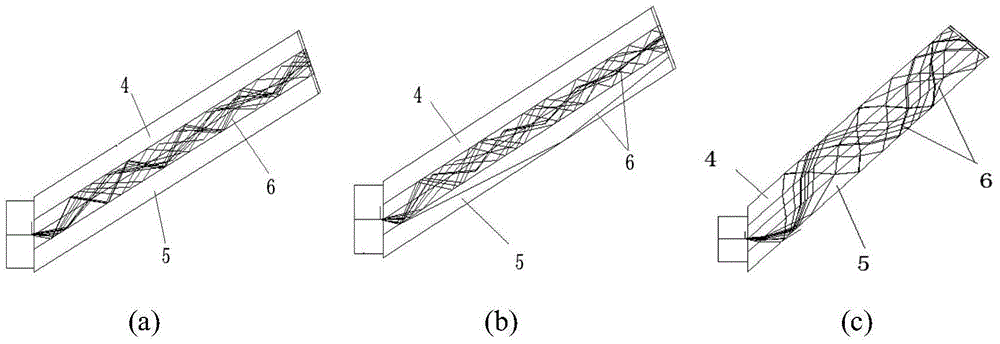

[0026] A novel imaging system with a large field of view in this embodiment includes three parts: a curved imaging lens 1 located at the front end, an optical fiber taper 2 and an imaging sensor 3 . The curved surface imaging lens 1 is composed of a plurality of spherical or hemispherical lenses or a combination of spherical and hemispherical lenses, each lens shares a spherical center, and its image surface is spherical. A diaphragm can be set at the center of the sphere, or stray light can be eliminated by setting a reasonable fiber taper numerical aperture and zoom ratio to realize the selection of the imaging beam. At this time, the fiber taper 2 acts as the aperture stop. The fiber cone 2 is spindle-shaped: wide in the middle and narrow at both ends. One end of the optical fiber taper 2 is a curved image surface, which is a spherical surface, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com