Flow rectifier in negative-pressure weighing chamber

A technology of negative pressure weighing chamber and equalizer plate, which is applied in the direction of air flow control components, etc., can solve the problems of flying dust, affecting production efficiency, and unsmooth work, and achieve the effects of reducing wind speed, simple structure, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

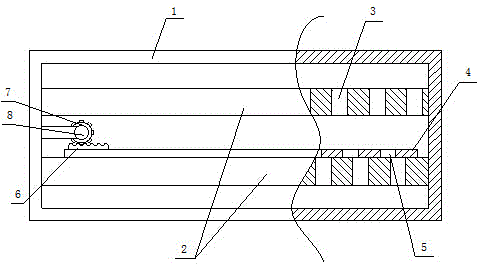

[0012] Such as figure 1 A current equalization device in a negative pressure weighing chamber is shown, which is installed between the air supply box and the working area. The current equalization device includes a fixed frame 1, and a flow equalizer plate 2 is fixed on the fixed frame 1 , a number of flow equalization holes 3 arranged in an array are arranged on the said flow equalizer 2, said flow equalizers 2 are at least two with a gap in the middle, and two adjacent said flow equalizers 2 The flow equalizing holes 3 on the top are arranged in a staggered manner, which can evenly distribute the components and reduce the wind speed.

[0013] The baffle plate 2 is provided with a baffle plate 4 for blocking the flow hole 3, and the baffle plate 4 is provided with a ventilation hole 5 having the same number and size as the flow hole 3 on the baffle plate 2. The pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com