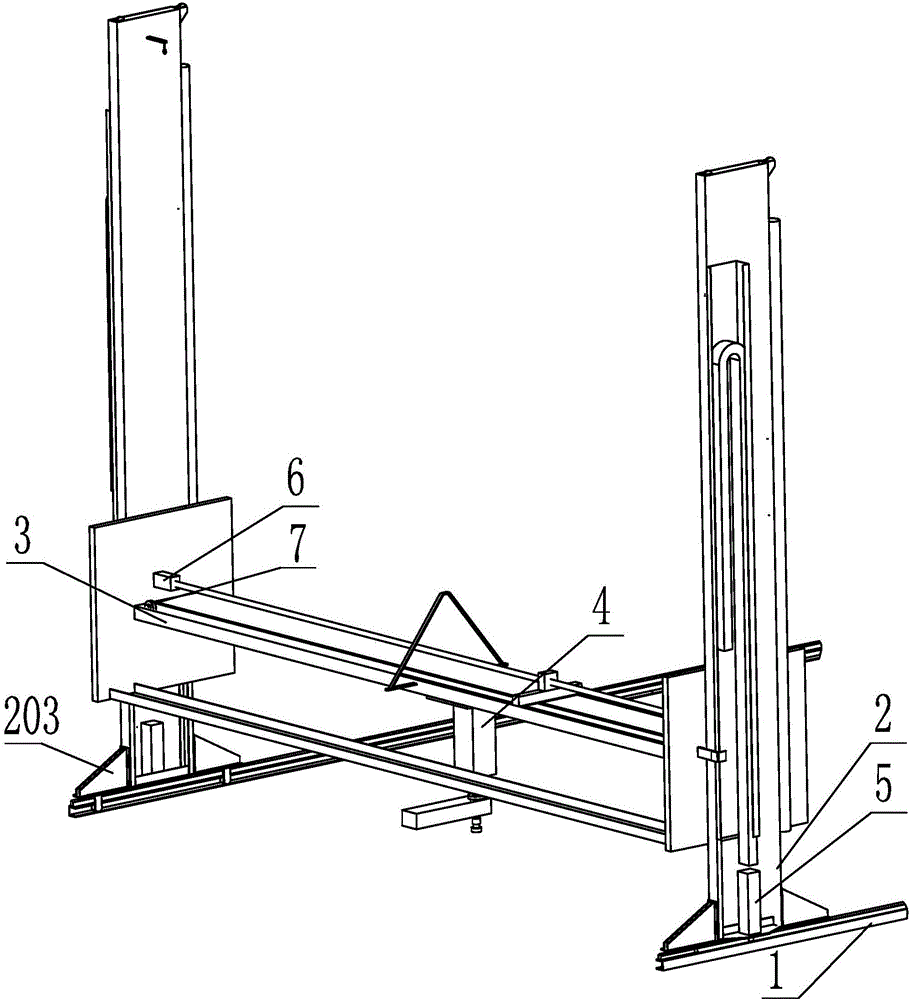

Building Contouring Machines

A technology for building outlines and forming machines, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of difficult manufacturing, twisting and shaking of mechanical structures, low forming accuracy, etc., and achieves a simple and reasonable overall structure. Overcomes wiggle and wobble, easy to fabricate and deploy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

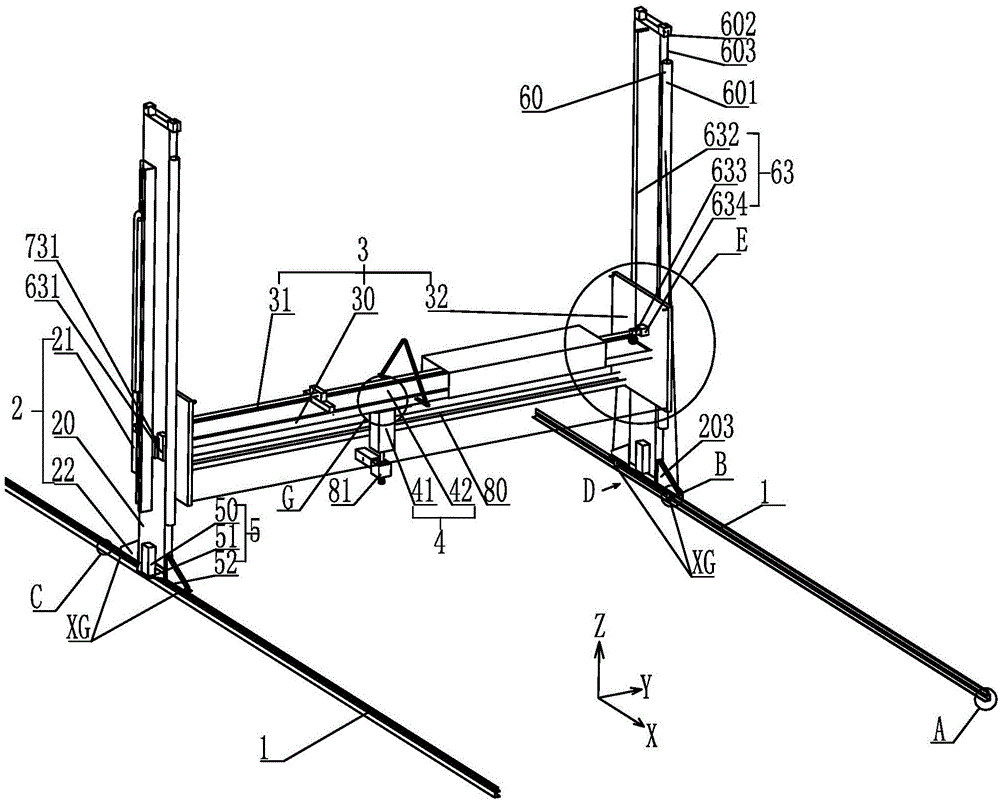

[0071] Figures 16 to 21 It shows a preferred embodiment of the second anti-rotation structure of the Z-direction guide rail pair ZG in the sliding fit mode: the second anti-rotation structure includes two groups arranged on the Z-direction moving guide rail 32 along the Z direction Sliding groove groups, each group of sliding groove groups includes two symmetrically arranged sliding grooves 322; a detent distance Lzz extending along the Z direction is provided between the two groups of sliding groove groups; two sliding grooves 322 of the same group of sliding groove groups slide A detent distance Lzx extending along the X direction is provided between the slots 322 . Figure 22 It shows another preferred embodiment of the second anti-rotation structure of the Z-guiding rail pair ZG in the rolling fit mode: the second anti-rotation structure includes two moving guide rails 32 along the Z direction. A set of scroll wheels, each set of scroll wheels includes two sets of symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com