Prefabricated external thermal insulation board, thermal insulation wall formed by its assembly and construction method

A technology for thermal insulation of walls and external insulation, which is applied in the direction of thermal insulation, walls, and building materials, etc. It can solve problems such as uncertain construction operation control methods, inadequate control measures, and insufficient thermal insulation performance, and achieve enhanced energy-saving and thermal insulation effects. The construction method is simple and easy to operate, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described in detail below through specific implementations.

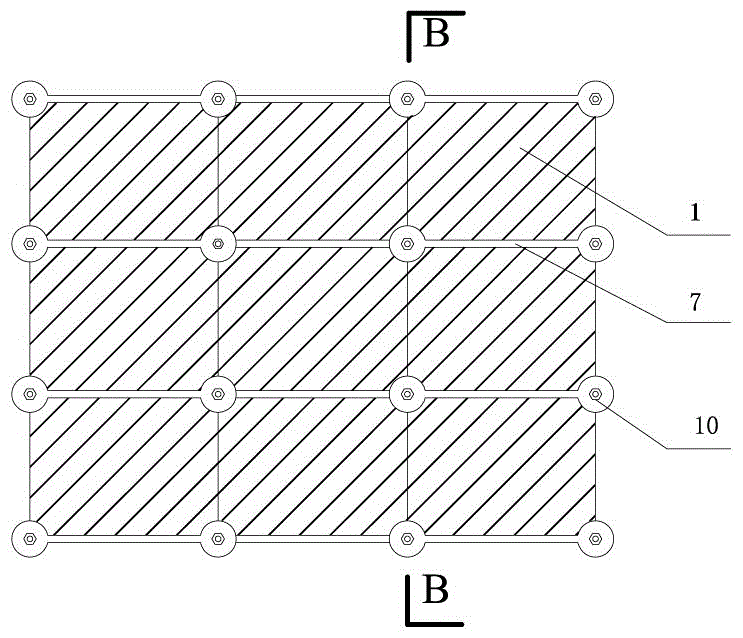

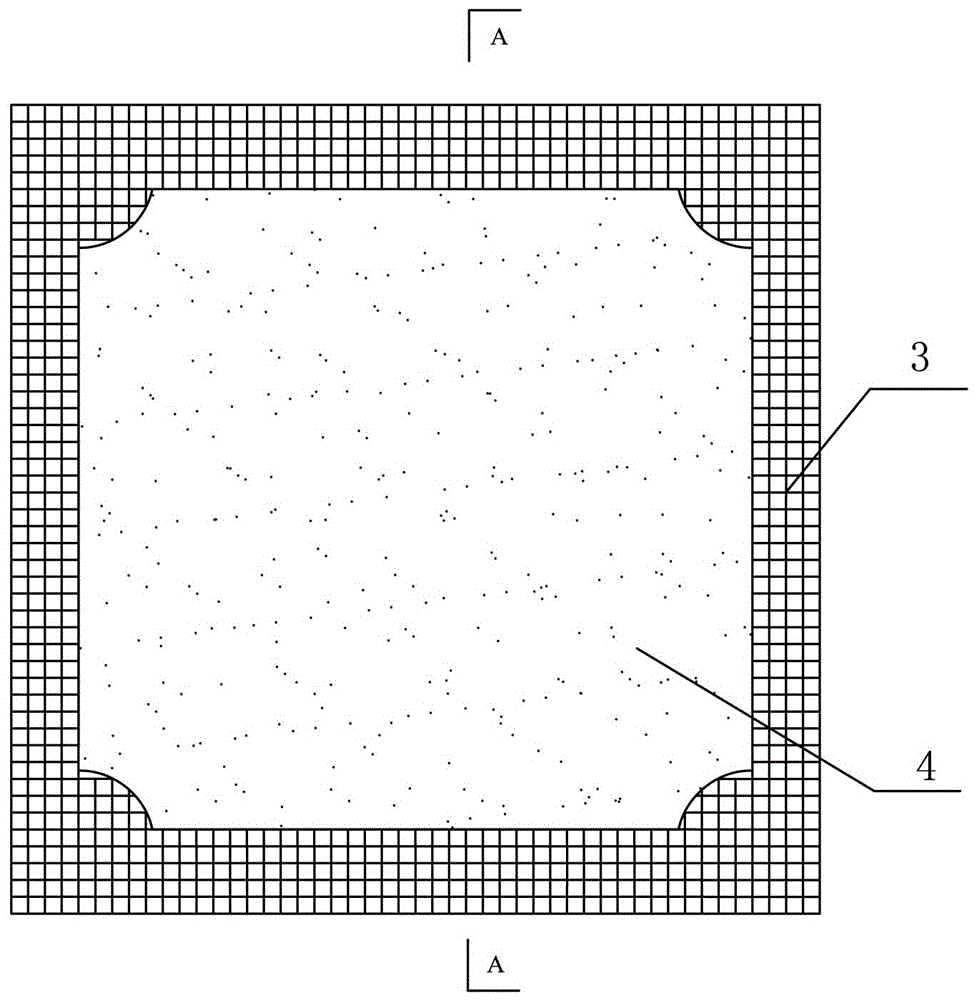

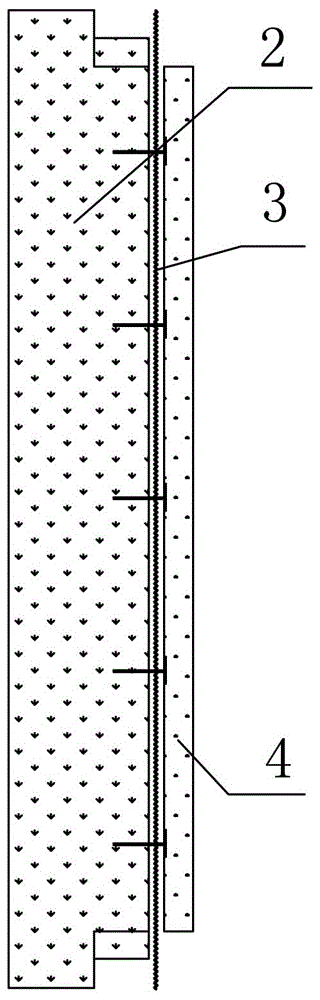

[0031] Such as Figure 1-9 As shown, a prefabricated external insulation board 1 includes an insulation board 2, a steel wire mesh sheet 3, and an anti-cracking mortar board 4. The upper and lower edges and four diagonal corners of the insulation board 2 are provided with transverse connection grooves 21 The insulation board is divided into an outer surface layer 22 and a wall layer 23. The steel wire mesh sheet 3 is fixed on the outer surface layer 22 of the insulation board 2 by fixing steel nails. The upper, lower and left sides of the steel wire mesh sheet 3 , The right four edges are larger than the upper, lower, left and right four edges of the insulation board 2 against the wall layer 23, and the anti-cracking mortar board 4 corresponds to the outer surface 22 of the insulation board 2 on the steel wire mesh 3 The anti-cracking mortar is ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com