A kind of supercritical method prepares nano-phosphorus-nitrogen intumescent flame retardant method

A supercritical, flame retardant technology, applied in the production of bulk chemicals, organic chemistry, etc., can solve the problems of large particle size, low flame retardant efficiency, and large impact on the mechanical properties of polymer matrix.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

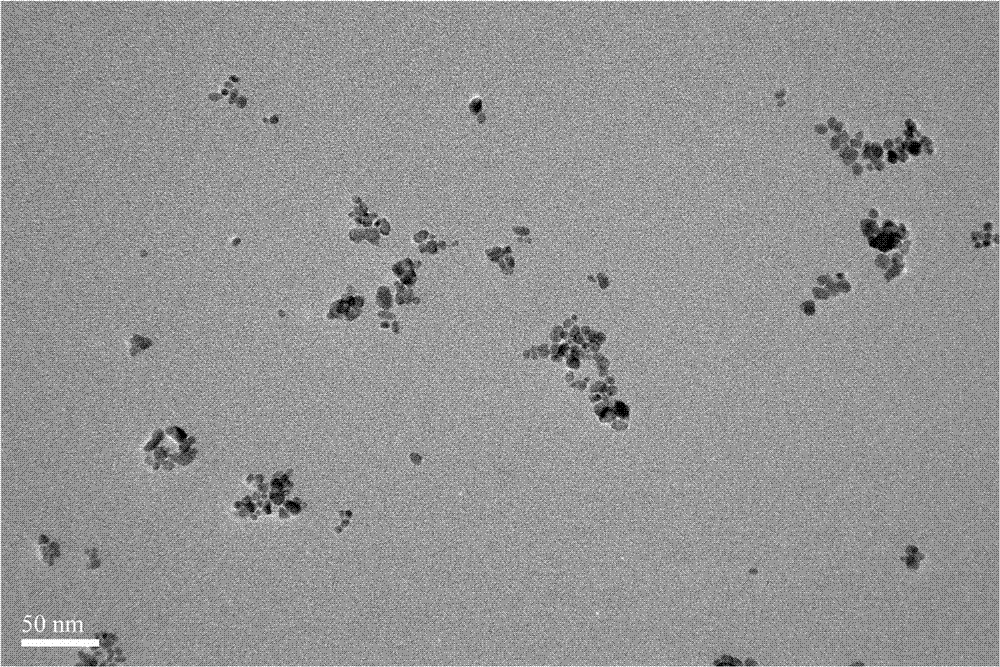

Embodiment 1

[0023] Accurately weigh a certain amount of melamine, phosphoric acid and surfactant according to the formula (the mass ratio of melamine and phosphoric acid is 1:1, and the quality of surfactant is 2% of the total mass of melamine and phosphoric acid), and add it to a certain amount of distilled water ( The amount of distilled water is 10% of the total mass of melamine and phosphoric acid), stirred to make it fully dissolved and prepared into a solution. Put the above solution into a supercritical reaction kettle, open the carbon dioxide steel cylinder, the carbon dioxide gas is cooled into a liquid by a refrigerator, and then pressurized by a high-pressure pump into the reaction kettle. Control a certain pressure (30MPa) and temperature (353K), and keep the pressure for a certain period of time (40min); open the pressure relief port to reduce the pressure in the supercritical reactor to normal pressure, and you can get nanometer particles with a number average particle size o...

Embodiment 2

[0025] Accurately weigh a certain amount of melamine, phosphoric acid and surfactant according to the formula (the mass ratio of melamine and phosphoric acid is 1.5:1, and the quality of surfactant is 0.5% of the total mass of melamine and phosphoric acid), and add it to a certain amount of distilled water ( The amount of distilled water is 50% of the total mass of melamine and phosphoric acid), stirred to make it fully dissolved and prepared into a solution. Put the above solution into a supercritical reaction kettle, open the carbon dioxide steel cylinder, the carbon dioxide gas is cooled into a liquid by a refrigerator, and then pressurized by a high-pressure pump into the reaction kettle. Control a certain pressure (40MPa) and temperature (363K), and keep the pressure for a certain period of time (20min); open the pressure relief port to reduce the pressure in the supercritical reactor to normal pressure, and you can get nanometer particles with a number average particle si...

Embodiment 3

[0027] Accurately weigh a certain amount of melamine, phosphoric acid and surfactant according to the formula (the mass ratio of melamine and phosphoric acid is 1:1.2, and the quality of surfactant is 1% of the total mass of melamine and phosphoric acid), and add it to a certain amount of distilled water ( The amount of distilled water is 20% of the total mass of melamine and phosphoric acid), stirred to make it fully dissolved and prepared into a solution. Put the above solution into a supercritical reaction kettle, open the carbon dioxide steel cylinder, the carbon dioxide gas is cooled into a liquid by a refrigerator, and then pressurized by a high-pressure pump into the reaction kettle. Control a certain pressure (35MPa) and temperature (363K), and keep the pressure for a certain period of time (60min); open the pressure relief port to reduce the pressure in the supercritical reactor to normal pressure, and you can get nanometer particles with a number average particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com