Eccentric hanger drawing machine

A puller and eccentric technology, which is applied in the field of eccentric lug pullers, can solve problems such as wear and short life, and achieve the effects of improving production efficiency, avoiding deformation or damage, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

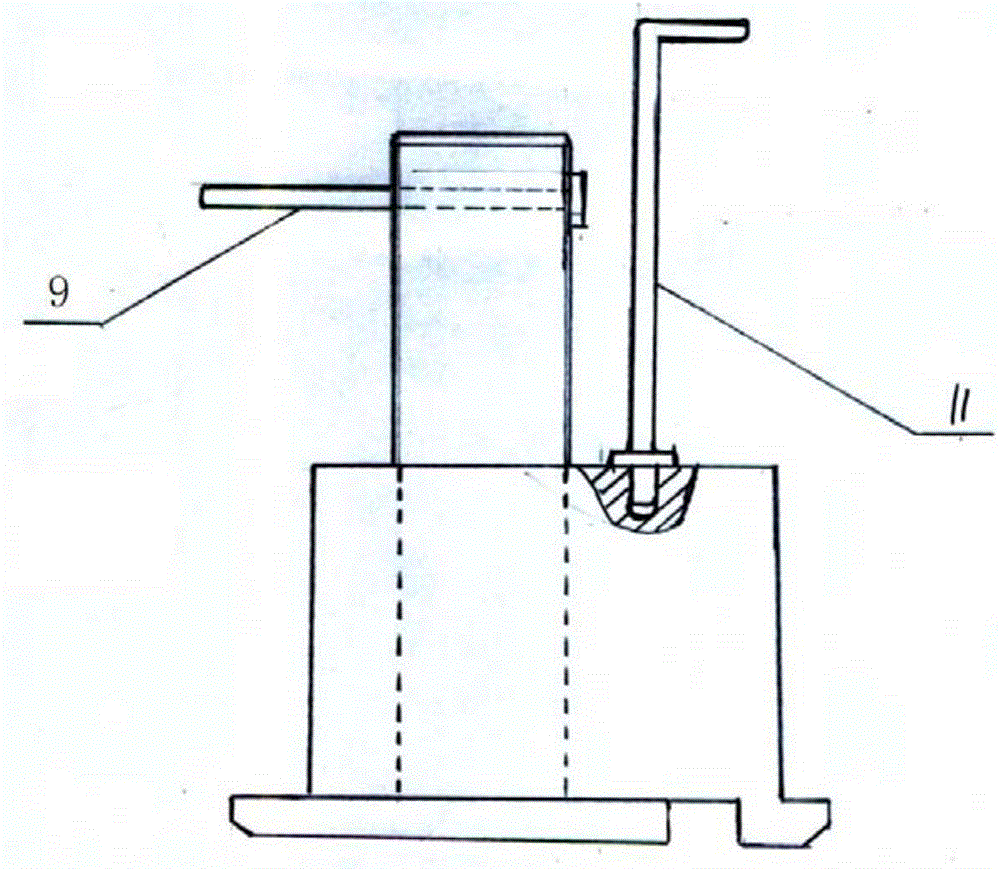

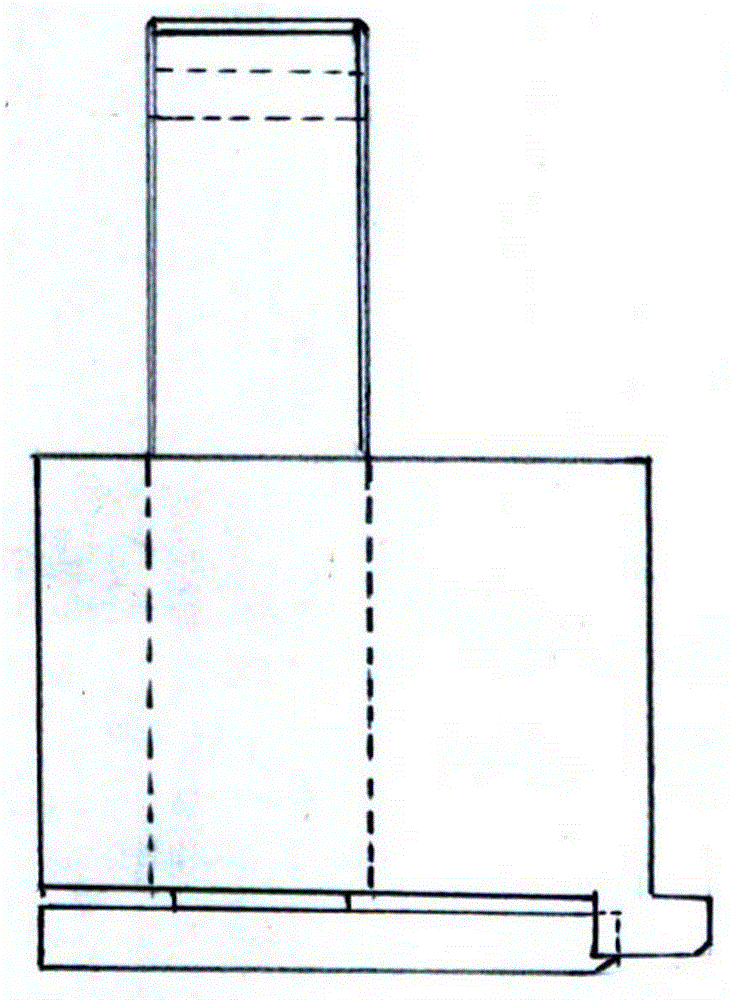

[0028] A kind of eccentric lug puller of the present invention, as Figure 1-11 As shown, it includes a drawing rod 1, the drawing rod is a screw whose axis extends in the vertical direction, and the lower end of the drawing rod is provided with an eccentric disk perpendicular to the direction of the axis. The eccentric hanging lug 5 is installed on the above-mentioned drawing rod 1, and the eccentric hanging lug 5 and the pulling rod can be rotated relatively. ear. The eccentric disc has an installation station that turns into the projection of the eccentric lug in the up and down direction and a drawing station that is used to hang and pull the right end surface of the workpiece after turning out the projection of the eccentric lug.

[0029] The above-mentioned eccentric hanging lug is a sleeve-shaped structure extending in the up-down direction, and the above-mentioned hanging lug is arranged on the lower side of the eccentric hanging lug and extends radially along the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com