Predicting method of rolling mill torque in slab rolling process

A technology of rolling process and prediction method, which is applied in the field of medium and heavy plate rolling, and achieves relatively accurate and accurate prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

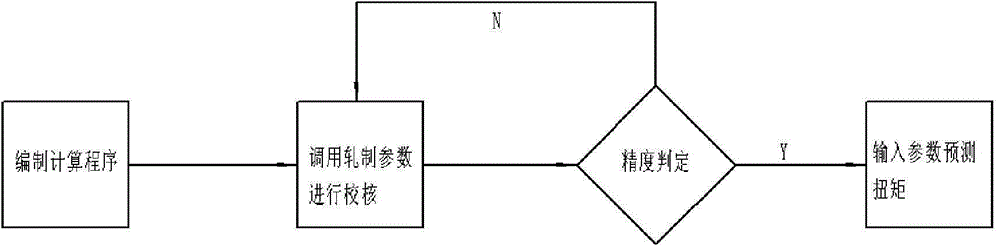

Method used

Image

Examples

Embodiment Construction

[0012] 1) Find the rolling process data of a certain steel grade according to the three-level data of the rolling mill, such as Q345B, and collect the process parameters of the rolling process, such as: calculating thickness of 300mm, pass reduction of 25mm, rolling width of 3800mm, measuring rolling The braking force is 42KNM.

[0013] 2) Substitute each parameter into the compiled calculation program, and adjust with the coefficient x until the calculated torque and the torque given in the system reach a certain accuracy. For example, when the coefficient of Q345B is 0.6, the two are closest, and the value of the two is about 2900KNm.

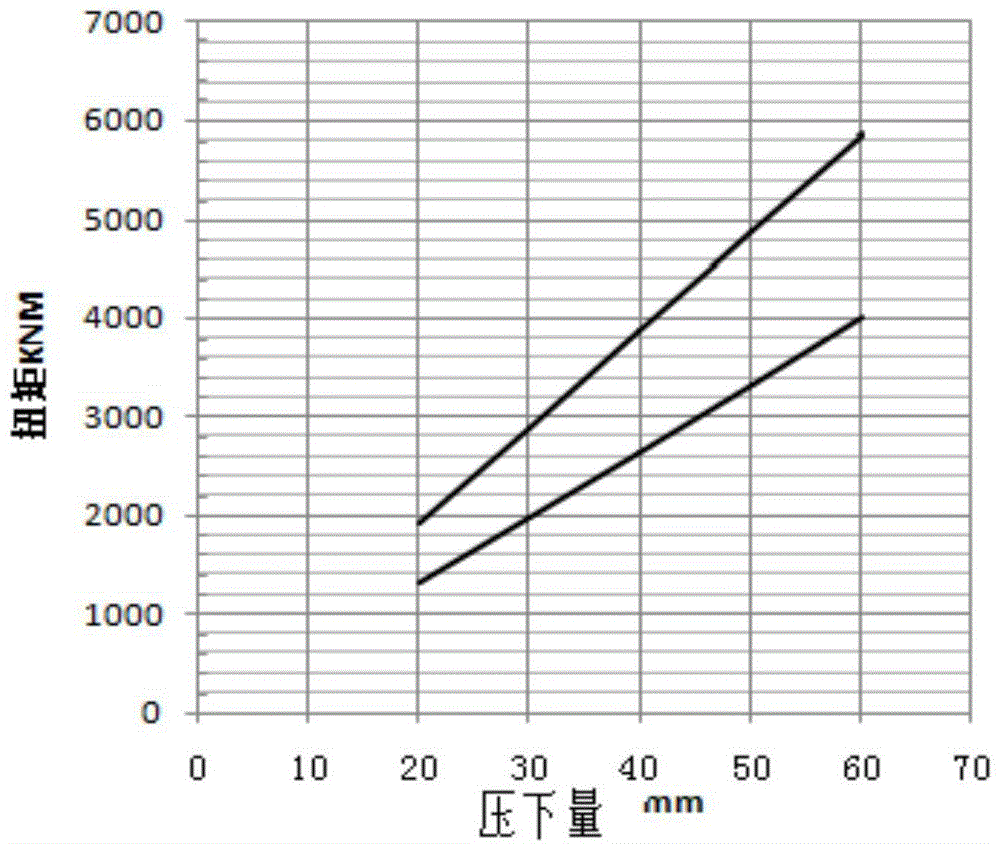

[0014] 3) Use the coefficient value to calculate the reduction and set the rolling parameters. For example, the upper limit of the rolling mill torque of a steel mill is 3200KNm. According to the calculation results, the Q345B of this specification reaches the reduction when the reduction is 50mm The upper limit.

[0015] image 3 To calculate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com