Processing method of novel primary-taste dried fruits and drying method of primary-taste dried fruits through Binchotan

A processing method and dried fruit technology, which is applied in the fields of fruit and vegetable preservation, fruit/vegetable preservation through dehydration, confectionary industry, etc., can solve the problems of products losing the flavor of ripe fresh fruit, food quality and safety incidents, and affecting the development of preserved fruit industry, etc., to achieve Good for color preservation, accelerated drying effect, and orange-yellow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

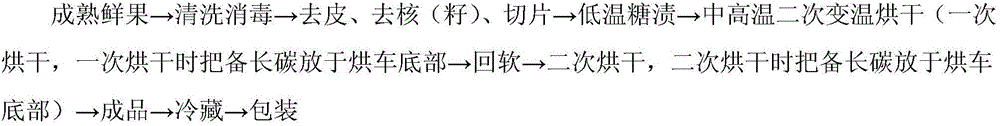

Image

Examples

Embodiment 1

[0048] Embodiment 1 A kind of processing method of novel original flavor dried mango

[0049] (1) Choose 200kg of fully ripe fresh Aiwen mangoes. Ripe Aiwen mangoes have a sugar content of about 18Bix, strong aroma, orange-yellow flesh, and soft tissue, which is good for preserving color, original flavor and candied sugar;

[0050] (2) Mango adopts 100ppm of ClO 2 Soak in the solution for 3 minutes for disinfection and cleaning;

[0051] (3) Fresh fruit is peeled and pitted, cut into slices with a thickness of about 1 cm, and the pulp yield is about 50%, that is, about 100 kg of mango slices;

[0052] (4) Spread the sliced mango slices flat in a stainless steel bucket, sprinkle white sugar evenly on the surface of the fruit slices, the proportion of white sugar added to the Aiwen mango slices is 25% of the weight of the fruit slices (ie 25kg), at 0-7 ° C The cold storage candied for 3-5 days, and the final sugar content of the sugar liquid is about 36Bix.

[0053] (5) Dra...

Embodiment 2

[0058] Embodiment 2 A kind of processing method of novel original flavor dried pineapple

[0059] (1) select fully ripe fresh pineapple 200kg, the ripe pineapple sugar content of this kind is about 15Bix, the fragrance is strong, sweet and sour, and the present embodiment selects caine (Tainong kind also can), and the pineapple variety fragrance of the present embodiment is strong, The tissue is soft, which is good for preserving the original flavor and candy of pineapple;

[0060] (2) The pineapple adopts the ClO of 100ppm 2 Soak in the solution for 3 minutes for disinfection and cleaning;

[0061] (3) After the pineapple is peeled, it is cut into circular slices with a thickness of about 1 cm, and then the circular slices are divided into four and cut into fan shapes. The pulp yield is about 50%, and the pineapple slices are about 100kg. ;

[0062] (4) Lay the sliced pineapple slices flat in a stainless steel bucket, sprinkle evenly white granulated sugar on the surface...

Embodiment 3

[0068] Embodiment 3 A kind of processing method of novel original taste dried papaya

[0069] (1) Select 200kg of fully ripe fresh papaya that reaches the best edible effect. What this embodiment selects is Tainong (wherein Hawaiian variety papaya is also available). The papaya of the variety selected in the embodiment has a strong fragrance after ripening, the flesh is red, and the tissue is soft, which is beneficial to preserve the original flavor and candied papaya;

[0070] (2) Papaya adopts 100ppm of ClO 2 Soak in the solution for 2 minutes for disinfection and cleaning;

[0071] (3) papaya is peeled and seeded, and papaya is cut into 4cm long, wide 2cm, and thickness is about 1cm.

[0072] (4) Lay papaya strips in a stainless steel barrel, sprinkle white sugar evenly on the surface of the fruit slices, the proportion of white sugar accounts for 25% (ie 35kg) of the papaya slices, and then carry out sugar dipping in a cold storage at 0-7°C for 5-7 sky.

[0073] (5) Dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com