Light Microscopy and Microscopy Methods

A technology of optical microscope and optical device, which is applied in the field of microscopy, can solve problems such as poor signal-to-noise ratio, achieve good signal-to-noise ratio, reduce sample light, and improve resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

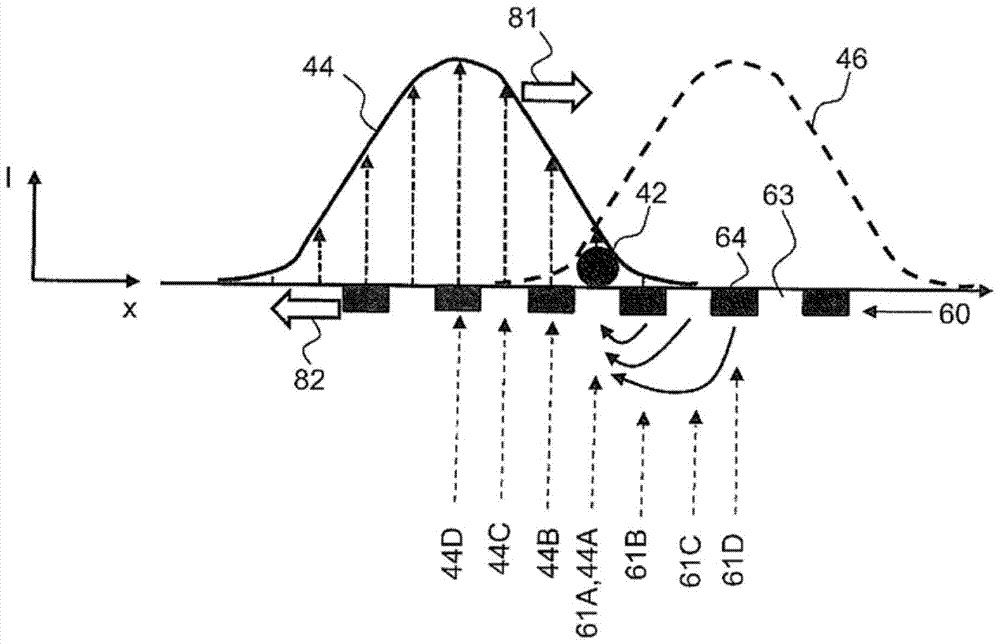

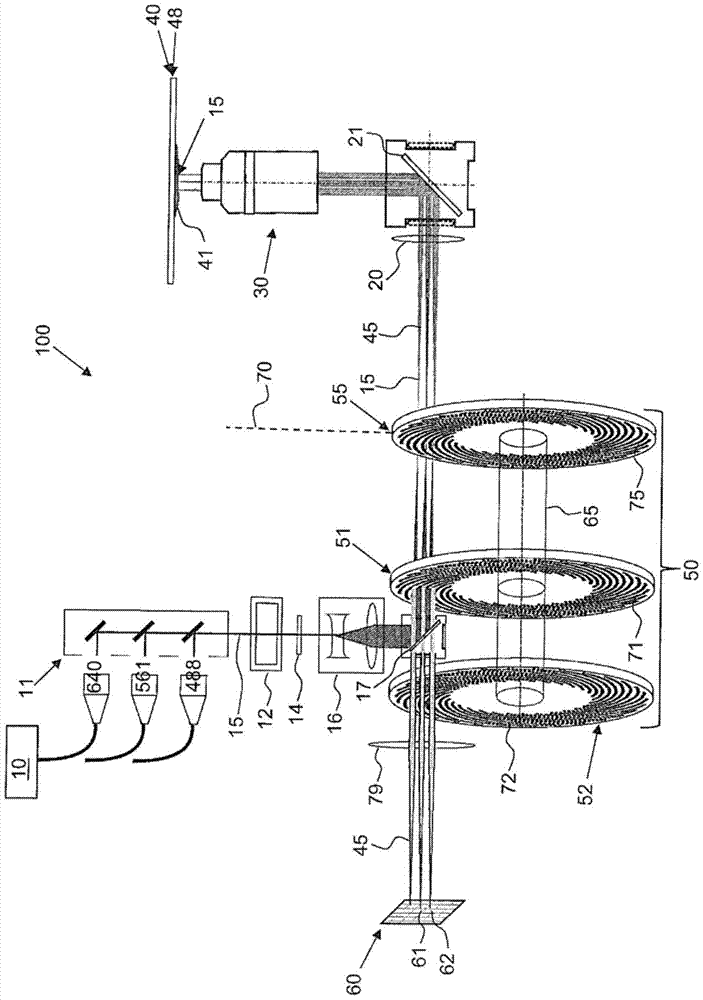

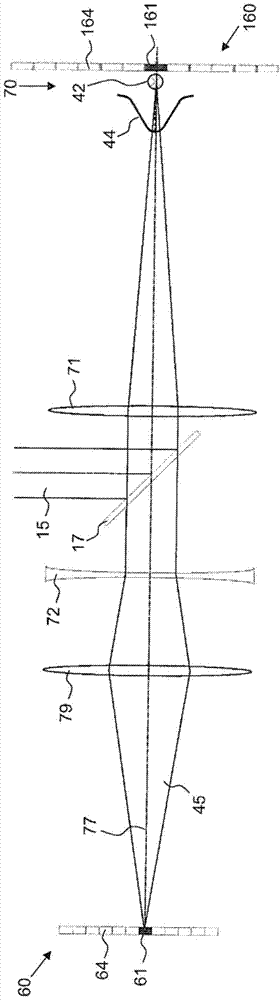

[0072] figure 2 An exemplary embodiment of an optical microscope 100 according to the invention is shown schematically. As main components, the optical microscope comprises a light source 10 for emitting illumination light 15, a sample plane 40, a detector device 60 for detecting the sample light 45, and a scanning device 50, on which the sample 41 to be investigated can be positioned. middle.

[0073] An illumination scanning movement of the illumination light beam 15 over the sample plane 40 is carried out by the scanning device 50 . Furthermore, the scanning device 50 moves the receiving region in the sample plane 40 , from which specific detector elements 61 , 62 of the detector device receive sample light. This movement is called probe scanning movement. By specially designing the scanning device 50, the directions of the illumination scanning movement and the detection scanning movement are always opposite to each other.

[0074] The light source 10 may include a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com