Electrical control module heat dissipation device

A technology of electronic control module and heat dissipation device, which is applied in the direction of cooling/ventilation/heating transformation, etc. It can solve the problems that the module cannot be lowered to an appropriate temperature, the life is reduced, and the electronic component module is burned, so as to achieve good heat dissipation and cooling effect and accelerate The heat dissipation process and the effect of ensuring the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

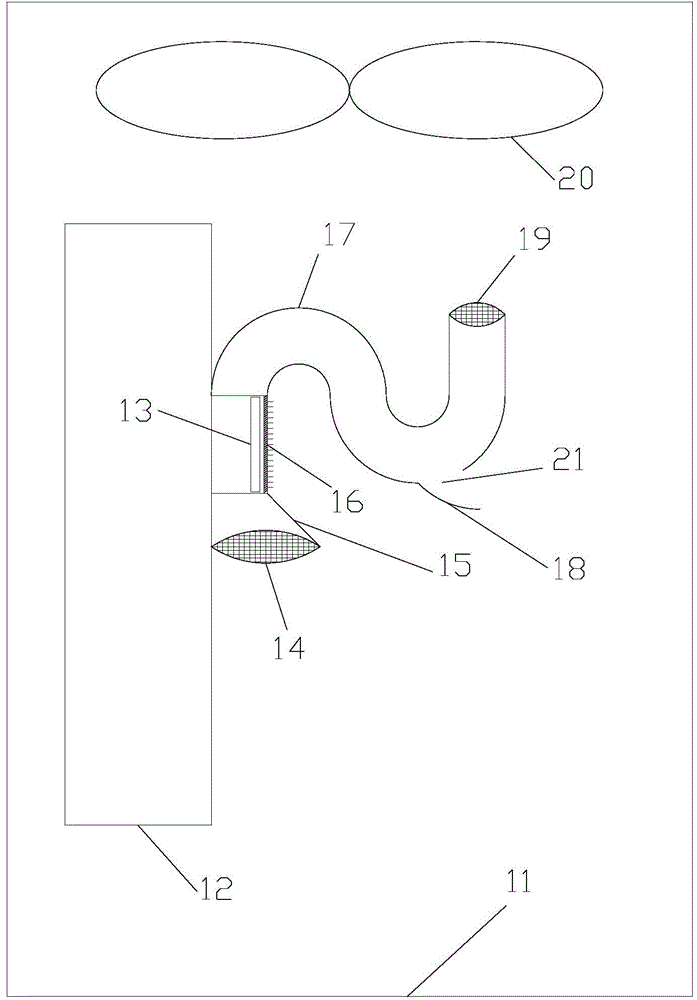

[0028] Such as figure 1 As shown, an electric control module cooling device includes an electric control box 12, an electric control module 13, a fan 20 and a radiator 16 arranged in the outdoor unit body 11, and the electric control module 13 is arranged in the electric control box 12, the fan 20 is arranged above the electric control module 13 and the radiator 16, and the radiator 16 is arranged at the end of the electric control module 13 away from the electric control box 12; The radiator 16 is provided with an air inlet and an air outlet, and the air inlet and outlet of the radiator 16 are respectively located at opposite ends of the electronic control module 13 . The installation location and installation qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com