Automatic charging pile

A technology of automatic charging and charging gun, which is applied in the direction of current collectors, electric vehicles, electrical components, etc., can solve the problems of manual operation, inconvenient use, and potential safety hazards, and achieve the goals of avoiding aging or damage, convenient use, and avoiding electric shock accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0022] The implementation of the present invention will be described in detail below in conjunction with specific embodiments.

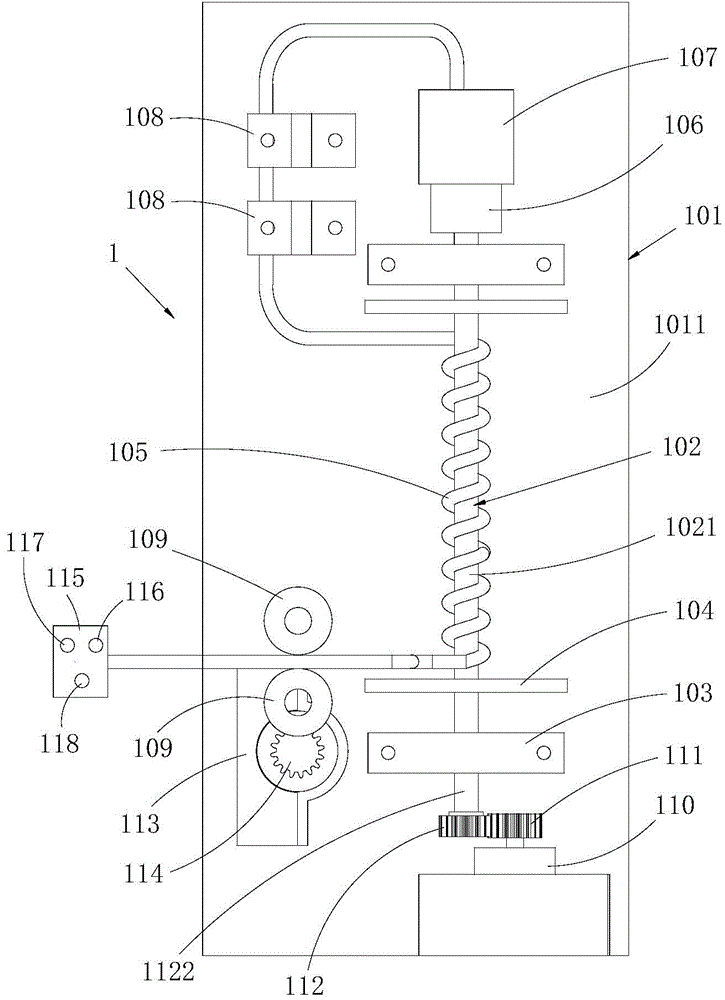

[0023] Such as figure 1 Shown are the preferred embodiments provided by the present invention.

[0024] The automatic charging pile 1 provided in this embodiment includes a box body 101, a sealed cavity 1011 is provided in the box body 101, and a rotating shaft 102 and two rotating seats 103 arranged in parallel and alternately arranged in the cavity 1011. The two ends of 102 are respectively rotatably inserted in the two rotating seats 103, and a winding section 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com