Voltage-regulating capacitance-regulating tap switch adopting vacuum arc-extinguishing chambers

A vacuum interrupter and tap changer technology, applied in transformers, variable transformers, electrical component structure associations, etc., can solve problems such as insulation capacity decline, phase-to-phase insulation breakdown, and phase-to-phase short-circuit accidents, and achieve convenient and safe operation. High performance and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

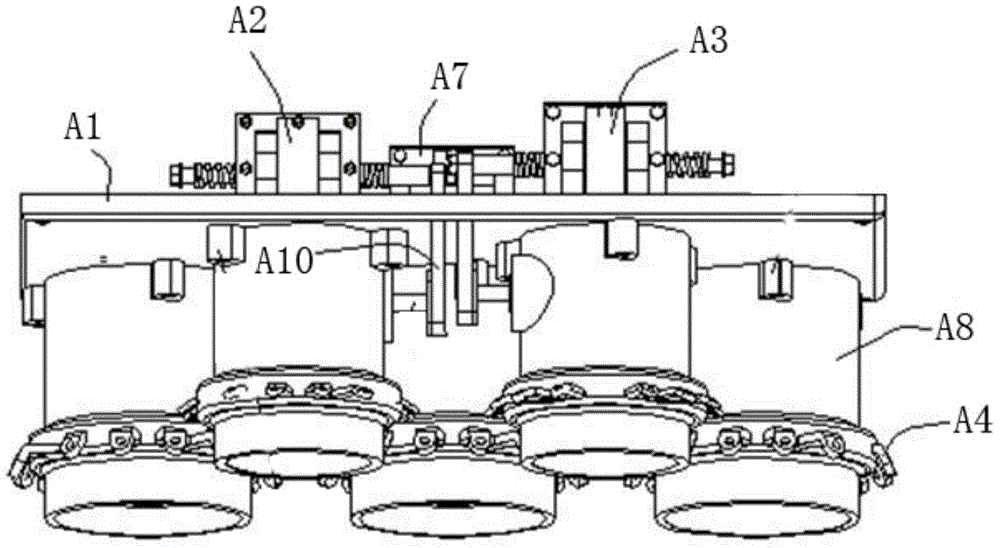

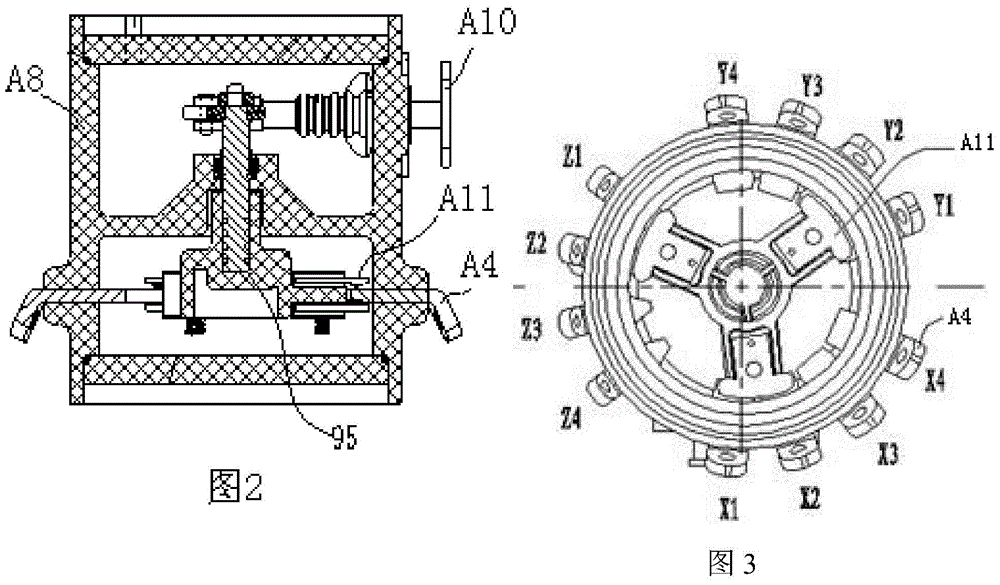

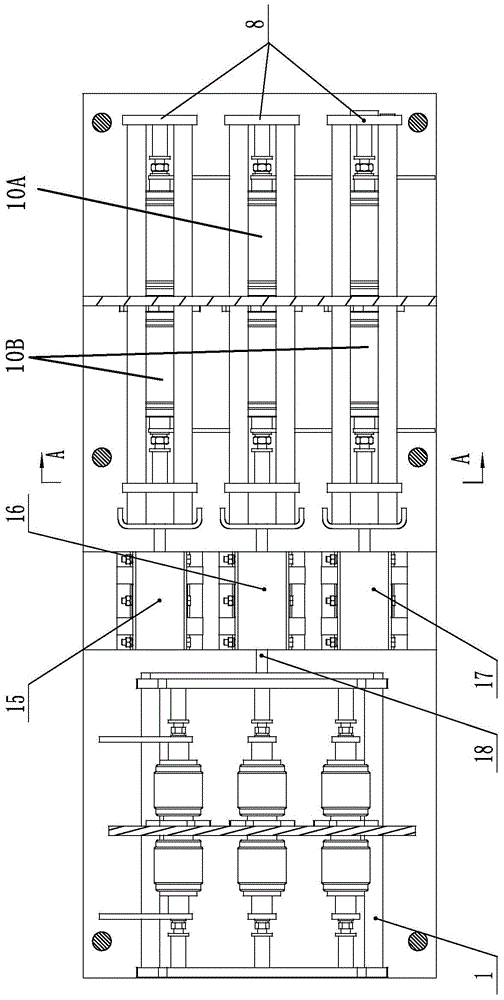

[0026] Such as Figure 4~Figure 7 As shown, the voltage regulating and capacity regulating tap changer using vacuum interrupter in the present invention is composed of a set of capacity regulating switches and capacity regulating operating mechanism, two groups of pressure regulating switches and their pressure regulating mechanisms; wherein the capacity regulating switch The group consists of three high-voltage double-break vacuum interrupters and six low-voltage double-break vacuum interrupters, which are used to switch the different tap contacts of the high-voltage side winding and the low-voltage side winding of the transformer, and realize the star-delta connection of the high-voltage side winding during action switching. Conversion and series-parallel conversion of low-voltage side windings to ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com