Shock absorber for motor vehicle with dual air chamber

A technology of motor vehicles and shock absorbers, which is applied in the direction of shock absorbers, gas shock absorbers, springs/shock absorbers, etc., can solve problems such as complex, complex structures, and difficult implementation, and achieve the effect of changing the effective stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

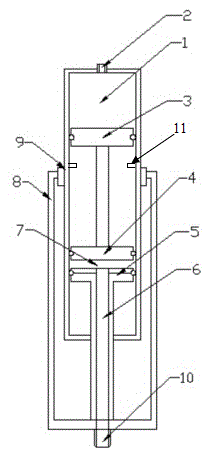

[0013] The structure of the double-chamber motor vehicle shock absorber of the preferred embodiment of the present invention is as follows: figure 1 As shown, it includes an outer tube 8, an inner tube 9, a first air chamber 7 and a second air chamber 1 that are socketed with each other; the outer tube 8 is a hard tube with one end open and one end closed, and the inner tube 9 is closed at both ends, and one end The closed opening is provided with a hard tube with a small hole. The end of the inner tube 9 with the small hole faces the bottom of the closed end of the outer tube 8 and is inserted into the outer tube 8 through the open end. The first air chamber 7 and the second air chamber 1 The first air chamber 7 includes the connecting rod 6 of the outer pipe 8, the main piston 5 of the first air chamber and the first air nozzle 10. One end of the outer pipe 8 is connected to the closed end of the outer pipe 8. At the bottom, the other end of the outer tube 8 passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com