A motor vehicle shock absorber

A technology for shock absorbers and motor vehicles, which is applied to gas shock absorbers and other directions, can solve problems such as complexity, difficulty in implementation, and complex structures, and achieve the effect of changing the effective stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

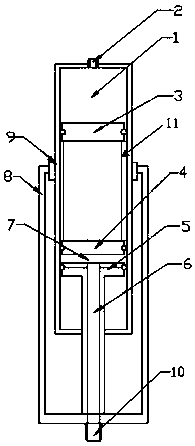

[0013] The motor vehicle shock absorber structure of the preferred embodiment of the present invention is as figure 1 As shown, it includes a first air chamber 7, a second air chamber 1, and an outer tube 8 and an inner tube 9 that are socketed in each other; the outer tube 8 is a hard tube with one end open and one end closed, and the inner tube 9 is closed at both ends, wherein A hard tube with a small hole in the closed mouth at one end. The end of the inner tube 9 with the small hole faces the bottom of the closed end of the outer tube 8 and is inserted into the outer tube 8 through the open end. The first air chamber 7 and the second air chamber 1. It is connected and arranged inside the inner tube 9 through the partition piston 4; it also includes the outer tube connecting rod 6, the main piston 5 of the first air chamber and the first air nozzle 10. One end of the outer tube connecting rod 6 is connected to the bottom of the closed end of the outer tube 8, The other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com