Equal-stiffness vibration isolator based on air floatation and magnetic floatation combination three-directional decoupling

A technology of equal stiffness and vibration isolator, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problem that the vibration isolator cannot achieve equal stiffness, and achieve the effect of good three-way vibration isolation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

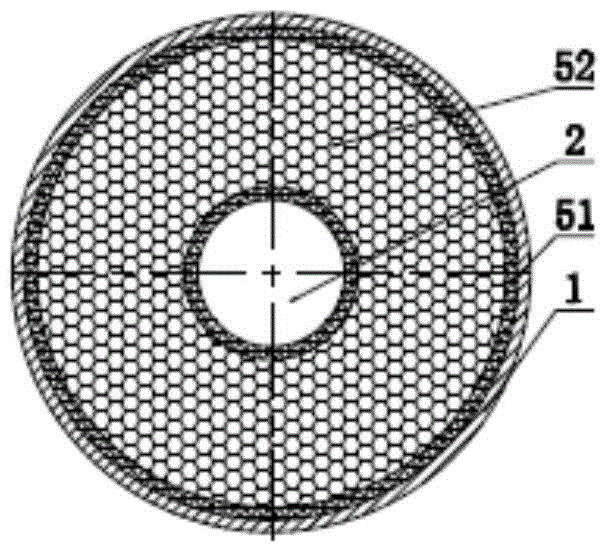

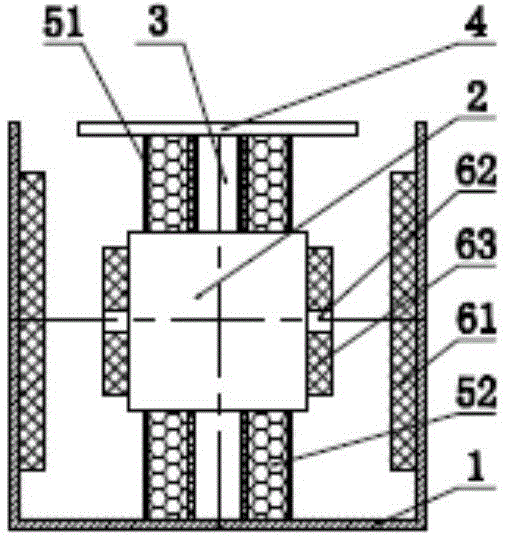

[0014] combine figure 1 and figure 2 , the three-way decoupling equal-stiffness vibration isolator based on the combination of air-flotation and maglev of the present invention includes an installation shell 1, a suspension block 2, a connecting rod 3, an electronic platform 4, an air-floating damping system, and a maglev damping system; the connecting rod 3 The lower end is installed on the suspension block 2, and the upper end is equipped with the electronic platform 4; the air-floating damping system includes an annular gas bag 51 and rare gas 52; the magnetic-floating damping system includes a main coil 61, a displacement sensor 62 and a secondary coil 63.

[0015] see figure 1 and figure 2 As shown, as an implementation example 1, the three-way decoupling equal stiffness vibration isolator based on the air suspension and mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com