A method and device for exploiting seabed surface natural gas hydrate by using ultrasonic waves

A natural gas and ultrasonic technology, which is used in the development of fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of expensive reagents, complicated instruments and equipment, and low extraction efficiency, and achieves easy implementation, simple principle, and convenient transmission. The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

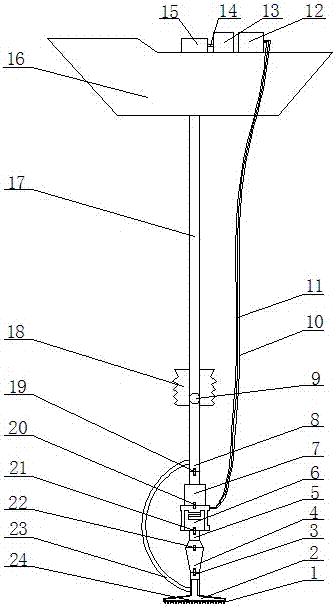

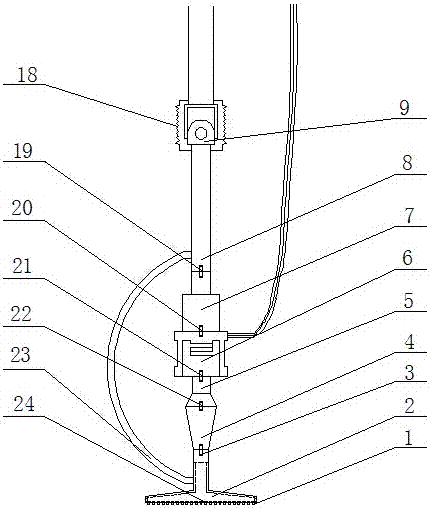

[0022] The seabed surface natural gas hydrate exploitation method provided by the present invention comprises the following steps:

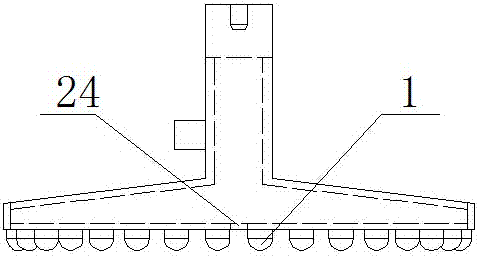

[0023] 1) The switch of the power supply device 12 on the workboat 16 is turned on, and the electric energy is input into the ultrasonic generator 6 through the cable 11, and the ultrasonic waves emitted by the ultrasonic generator 6 are transmitted to the surface layer of the seabed through the transducer 5, the ultrasonic concentrator 4, and the crushing head 2 , the ultrasonic wave drives the vibration of the crushing head 2 to interact with the natural gas hydrate, breaking the natural gas hydrate on the seabed surface into granular slurry;

[0024] 2) Start the slurry pump 15 on the working boat 16, suck the natural gas hydrate particle slurry through the suction hole 24 on the crushing head 2, flow through the inner cavity of the hose C23, the adjustment arm 8, and the pipe string 17, and suck it to In the natural gas hydrate decomposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com