Subway car depot testing line composite vibration-isolation barrier

A technology for subway depots and test lines, which is applied in the fields of protection devices, buildings, infrastructure engineering, etc., can solve the problems of the emergence and development of subway depots with a short history, different spatial relationships, and complex spectral components, and achieves a significant vibration isolation effect. , the effect of reducing additional vibration and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

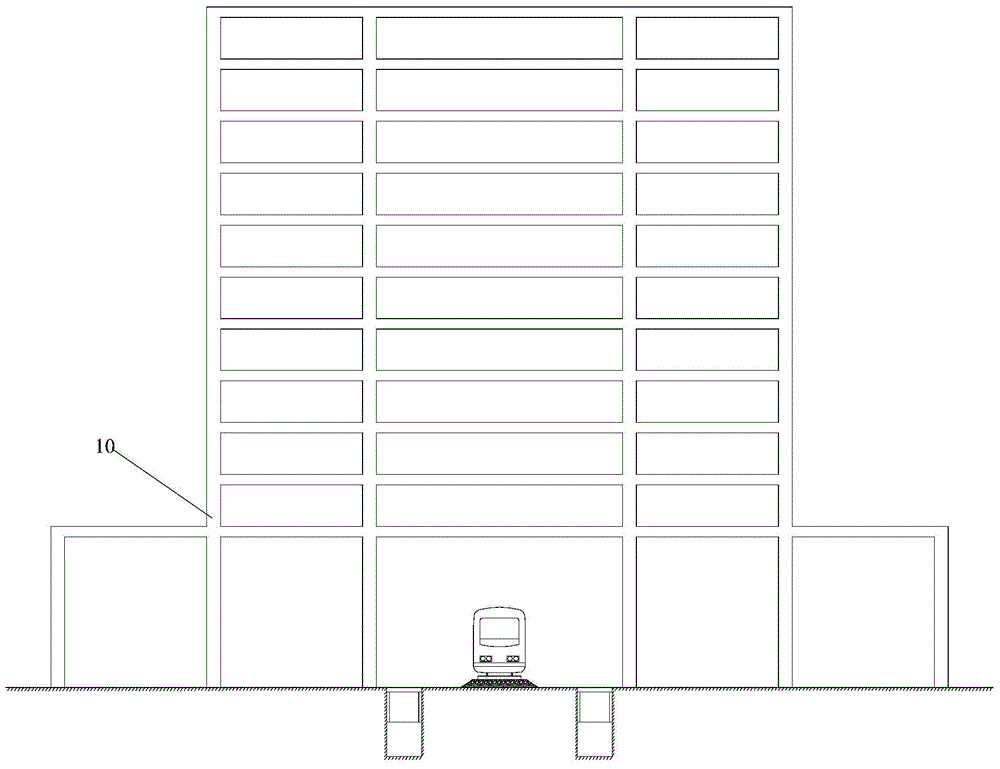

[0027] Such as figure 1 As shown, the composite vibration isolation barrier is set up on the test run line of the subway depot with the superstructure property, and the Rayleigh wavelength λ R It is 6.0m.

[0028] The construction steps are as follows:

[0029] A. First determine the size of the composite vibration isolation barrier (D×W1×S) as 4.0m×2.0m×4.5m, of which the size of the physical barrier (D1×W1×S) is 2.0m×2.0m×4.5m, the cable The size of the trench (D2×W2×S) is 1.75m×1.7m×4.5m, the size of the top cover (D3×W1×S) is 0.25m×2.0×4.5m, and the thickness W3 of the cable trench protection wall is 0.15m .

[0030] B. According to the size determined above, excavate an empty trench with a width of 2.0m and a depth of 2.0m at a distance of 4.5m from the center line of the track, and carry out mud protection according to the thickness of the cable trench protection wall of 0.15m to ensure the stability of the soil around the cable trench .

[0031] C, prepare industri...

Embodiment 2

[0039] Such as figure 1 As shown, the composite vibration isolation barrier is set up on the test run line of the subway depot with the superstructure property, and the Rayleigh wavelength λ R It is 7.7m.

[0040] The construction steps are as follows:

[0041] A. First determine the size of the composite vibration isolation barrier (D×W1×S) as 6.0m×2.0m×5.5m, of which the size of the physical barrier (D1×W1×S) is 3.0m×2.0m×5.5m, the cable The size of the trench (D2×W2×S) is 2.75m×1.7m×5.5m, the size of the top cover (D3×W1×S) is 0.25m×2.0×5.5m, and the thickness W3 of the cable trench protection wall is 0.15m .

[0042] B. According to the size determined above, excavate an empty trench with a width of 2.0m and a depth of 3.0m at a distance of 5.5m from the center line of the track, and carry out mud protection according to the thickness of the cable trench protection wall of 0.15m to ensure the stability of the soil around the cable trench .

[0043] C, prepare industri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com