An anti-sluggish tool for reducing friction, reducing drag, saving energy and increasing efficiency

A technology for reducing friction and drag, tools, applied in drilling tools, drilling equipment, earth-moving drilling and other directions, can solve problems such as the impact of the normal operation of the drill bit, the impact of the rock-breaking effect, and the stuck drill, so as to alleviate the phenomenon of stuck drilling and pressure holding, The effect of improving rock breaking efficiency and stable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

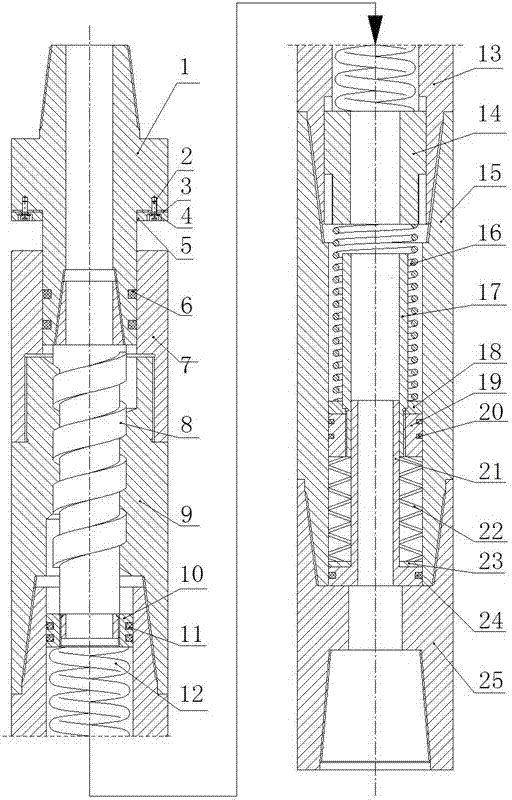

[0019] The present invention will be further described below in conjunction with accompanying drawing:

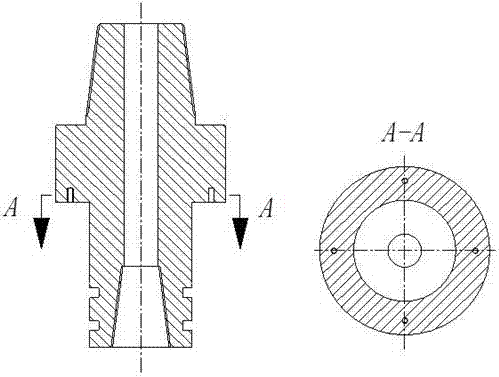

[0020] see figure 1 The anti-sluggish tool for reducing friction, reducing drag, saving energy and increasing efficiency includes an upper joint assembly, a transmission assembly, a vibration-absorbing assembly, and a lower joint 25. The transmission assembly is installed at the front end of the transmission assembly, and the front end of the transmission assembly is connected with the vibration-absorbing assembly; The gasket 3 and the rubber ring 5 are fixedly connected to the upper joint 1, and the rubber ring 5 is used to buffer the impact generated when the short joint 7 moves backwards and contacts the upper joint 1, and at the same time avoid the rear end of the short joint 7 from directly contacting the upper joint 1, Thereby reducing the vibration generated when the tool is working.

[0021] The transmission assembly includes a spiral nipple 8, a spiral outer cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com