Presser foot for template sewing of zigzag sewing machine

A sewing machine and presser foot technology, which is applied in the direction of sewing machine components, sewing equipment, cloth pressing mechanism, etc., can solve problems such as failure to reach, wrinkles, and unsightly products, and achieve the effect of beautiful stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

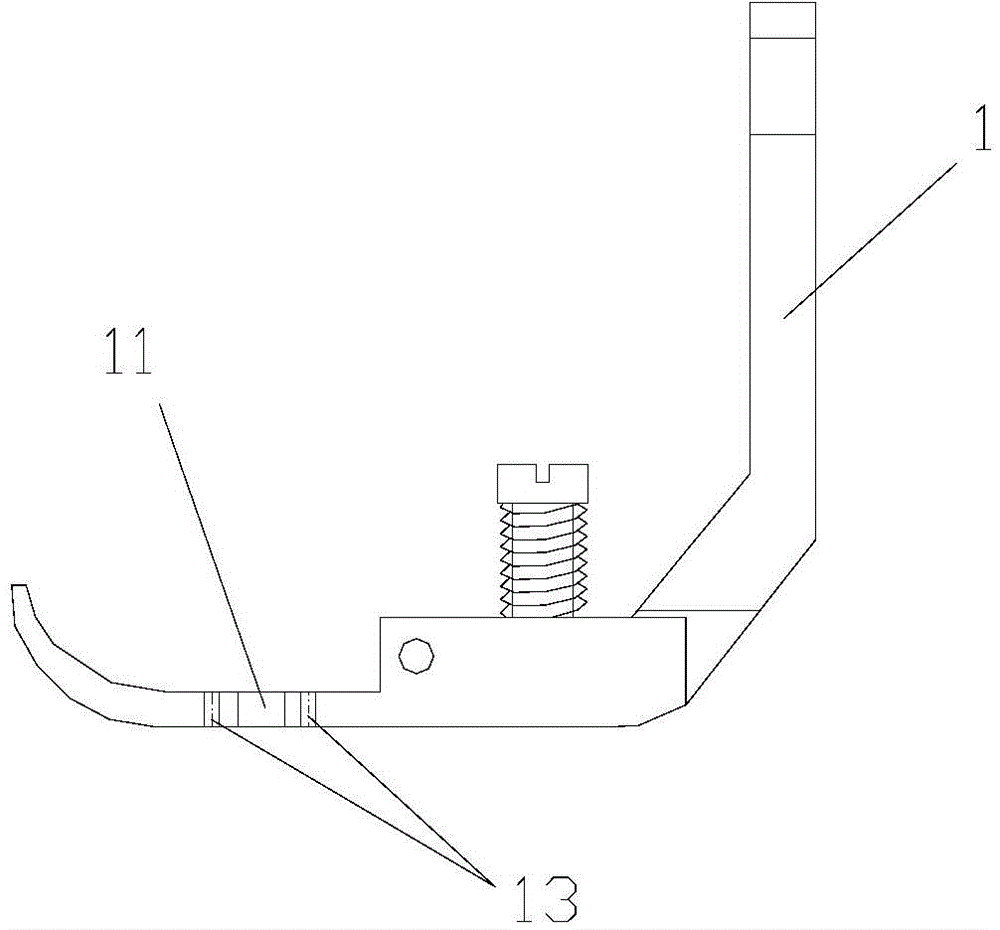

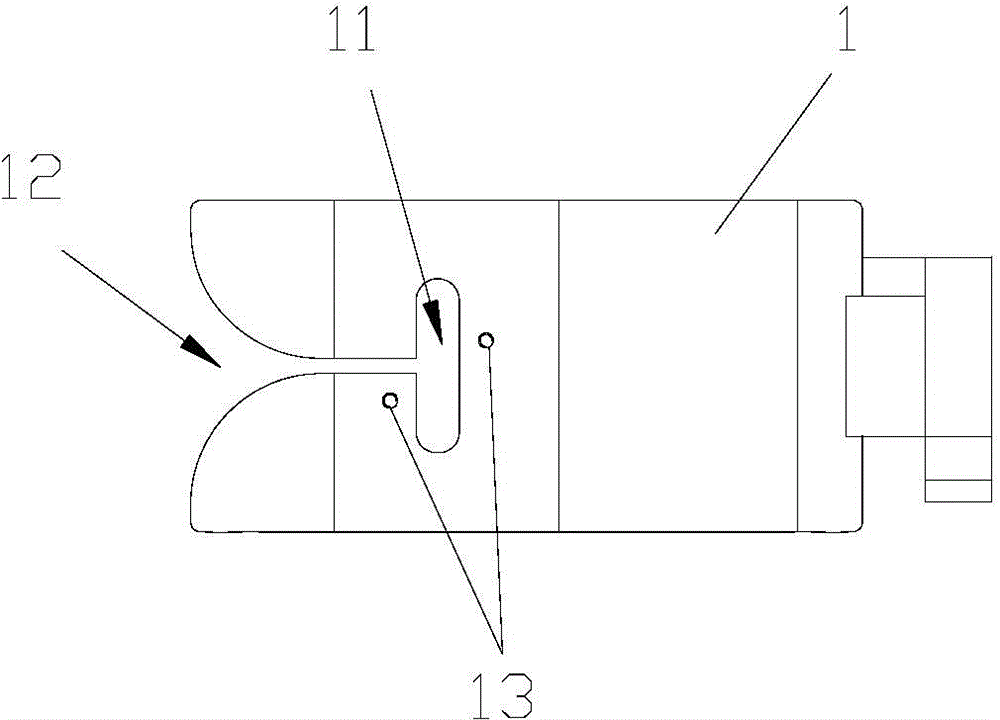

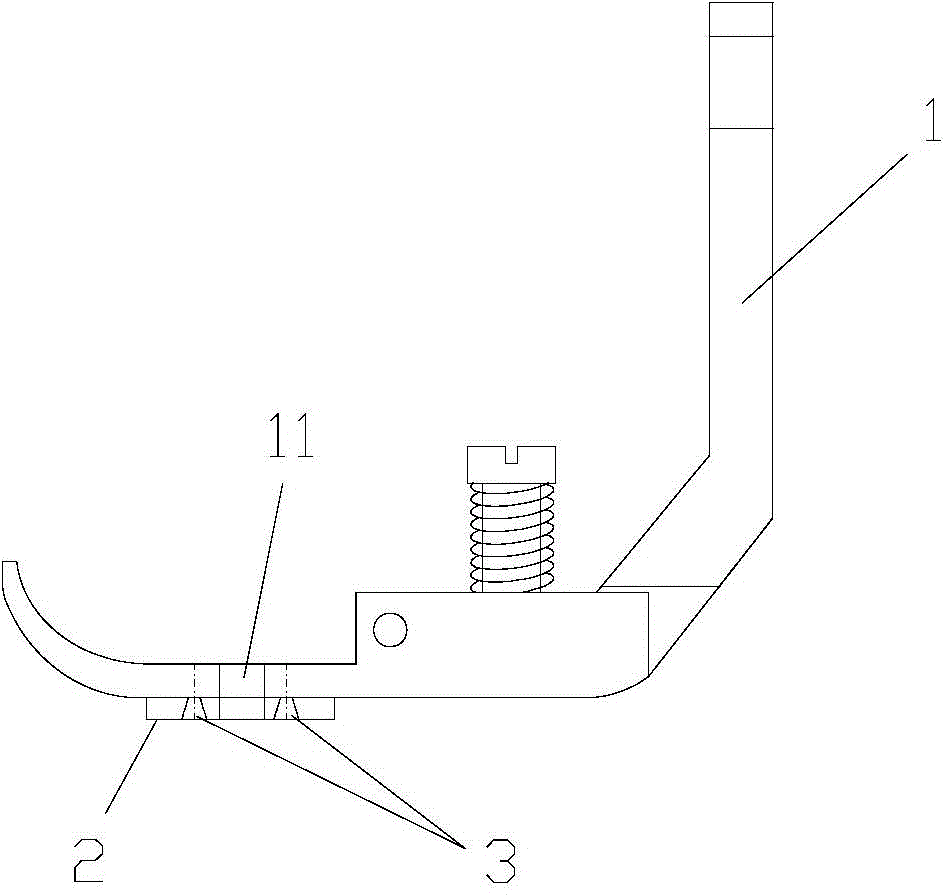

[0020] see Figure 1 to Figure 5 , a presser foot used for template sewing of zigzag sewing machines, comprising a presser body 1, on which a strip-shaped pinhole 11 extending along the width direction of itself is opened, and the front part of the presser body 1 has The gradually opened front opening 12 communicates with the bar-shaped pinhole 11 . The bottom of the strip-shaped pinhole 11 is also provided with a boss 2 protruding downwards to snap into the groove of the template, and the strip-shaped pinhole 11 penetrates the boss 2 downward.

[0021] Such as Figure 4 with 5 As shown, the boss 2 is detachably installed on the presser body 1, and the bottom surface of the presser body 1 is provided with a threaded hole 13, and the boss 2 is connected to the presser body 1 through the threaded connector 3 matched with the threaded hole 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com