Special-purpose quick dry non-trace environmental protection rust-proof oil for nickeled piece and preparation method

An anti-rust oil and environmental protection technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of unenvironmental protection, strong human harm, and not easy to clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh the following parts by weight:

[0039]

[0040] The preparation method of quick-drying non-trace environmentally friendly anti-rust oil for nickel-plated parts is as follows:

[0041] (1) Add naphthenic base oil and white mineral oil into the reaction kettle, heat to 80°C, and stir well.

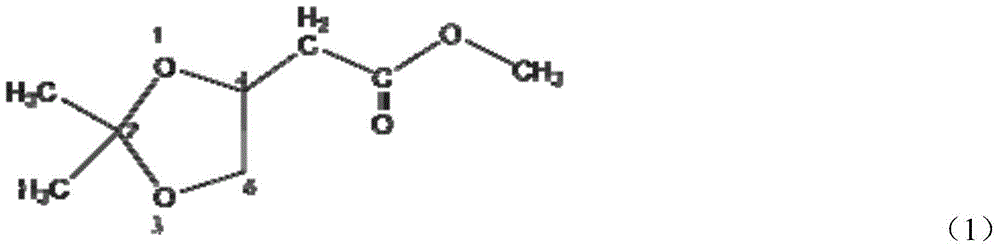

[0042] (2) Put sodium petroleum sulfonate, calcium petroleum sulfonate, benzotriazole, ASI-80, (2,2-dimethyl-1,3-dioxolane-4-yl)-acetate The esters were added to the reaction kettle in order, the temperature was lowered to 40°C after continuous stirring for 1 hour, and stirring was continued for 20 minutes.

[0043] (3) Add D50 mineral spirits and 2,6-di-tert-butyl-p-cresol antioxidant to the reaction kettle, cool to 35°C, continue stirring for 30 minutes, the system is a uniform transparent and clear liquid, and the nickel-plated parts are obtained. Special quick-drying non-marking environmentally friendly anti-rust oil.

Embodiment 2

[0045] Weigh the following parts by weight:

[0046]

[0047]

[0048] The preparation method of quick-drying non-trace environmentally friendly anti-rust oil for nickel-plated parts is:

[0049] (1) Add naphthenic base oil and white mineral oil into the reaction kettle, heat to 80°C, and stir well.

[0050] (2) Put sodium petroleum sulfonate, calcium petroleum sulfonate, benzotriazole, OPS-75E, (2,2-dimethyl-1,3-dioxolane-4-yl)-acetate The esters were added to the reaction kettle in order, the temperature was lowered to 40°C after continuous stirring for 1 hour, and stirring was continued for 20 minutes.

[0051] (3) Add D50 mineral spirits and 2,6-di-tert-butyl-p-cresol antioxidant to the reaction kettle, cool to 35°C, continue stirring for 30 minutes, the system is a uniform transparent and clear liquid, and the nickel-plated parts are obtained. Special quick-drying non-marking environmentally friendly anti-rust oil.

Embodiment 3

[0053] Weigh the following parts by weight:

[0054]

[0055]

[0056] The preparation method of quick-drying non-trace environmentally friendly anti-rust oil for nickel-plated parts is:

[0057] (1) Add naphthenic base oil and white mineral oil into the reaction kettle, heat to 80°C, and stir well. (2) Press sodium petroleum sulfonate, calcium petroleum sulfonate, benzotriazole, 9218LA, (2,2-dimethyl-1,3-dioxolane-4-yl)-methyl acetate Sequentially add them to the reaction kettle, continue stirring for 1 hour, then cool to 40°C, and continue stirring for 20 minutes.

[0058] (3) Add D50 mineral spirits and 2,6-di-tert-butyl-p-cresol antioxidant to the reaction kettle, cool to 35°C, continue stirring for 30 minutes, the system is a uniform transparent and clear liquid, and the nickel-plated parts are obtained. Special quick-drying non-marking environmentally friendly anti-rust oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com