Hot continuous rolling production line finishing mill front vertical roller short stroke control method

A technology of short-stroke control and finishing mill, which is applied in the direction of rolling force/roll gap control, etc. It can solve problems such as damage to equipment, steel clamping at the vertical roll of finishing rolling, rolling waste accidents, etc., to reduce rolling waste and avoid vertical roll Clamp steel, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

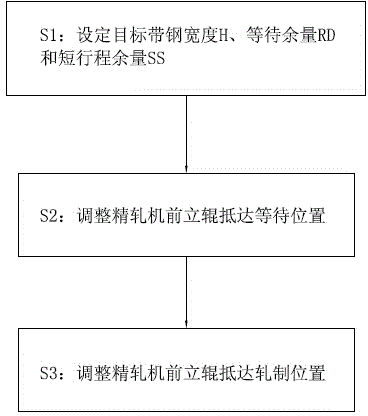

[0037] S1: Set target strip width H, waiting margin RD and short stroke margin SS;

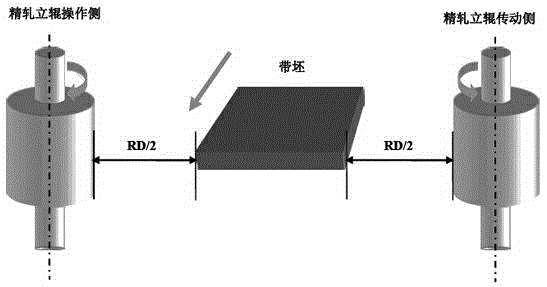

[0038] S2: Adjust the front vertical roller of the finishing mill to reach the waiting position. The specific process is: use the sensor to measure the distance in real time, and the two front vertical rollers of the finishing mill will move synchronously, and adjust the distance between any one of the front vertical rollers of the finishing mill and the target strip. is RD / 2, such as image 3 shown;

[0039] S3: Adjust the front vertical rolls of the finishing mill to reach the rolling position. The specific realization process is: two front vertical rolls of the finishing mill move inward synchronously (RD-SS) / 2.

[0040] The advantage of this method is that the distance between the waiting positions is relatively large, the accuracy of distance measurement is relatively low, and it is relatively easy to adjust.

Embodiment 2

[0042] S1: Set target strip width H, waiting margin RD and short stroke margin SS;

[0043] S2: Adjust the front vertical roll of the finishing mill to reach the waiting position. The specific realization process is: adjust the distance between the two front vertical rolls of the finishing mill to be H+RD;

[0044] S3: Adjust the front vertical roll of the finishing mill to reach the rolling position. The specific implementation process is to use the sensor to measure the distance in real time, and the two front vertical rolls of the finishing mill will move synchronously. The distance is SS / 2, such as Figure 4 shown.

[0045] The advantage of this method is that it can effectively shorten the waiting time, and at the same time, the smaller the distance, the smaller the adjustment range and the shorter the adjustment time.

[0046] According to the above steps, in the case of rolling special steel grades and other production abnormalities, the operator can also flexibly cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com