Simple double-sided dip-coating metering device

A metering device, double-sided technology, which is applied to devices for coating liquid on surfaces, coatings, etc., can solve the problems of inconvenient metering and adjustment of the coating layer, difficult to achieve accurate metering control of the coating layer, and complex structure, etc. Achieve direct and convenient metering control, convenient metering control, and accurate metering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

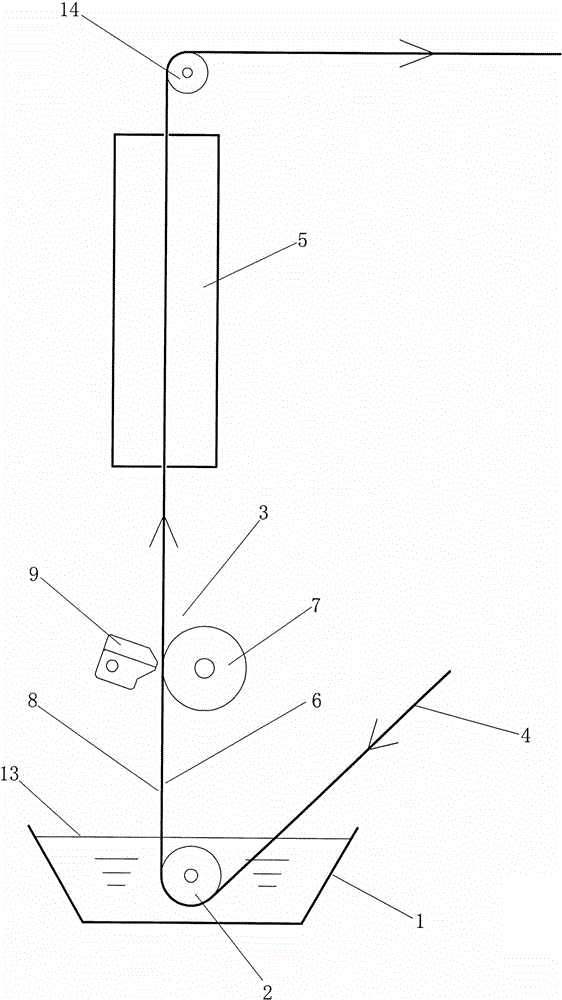

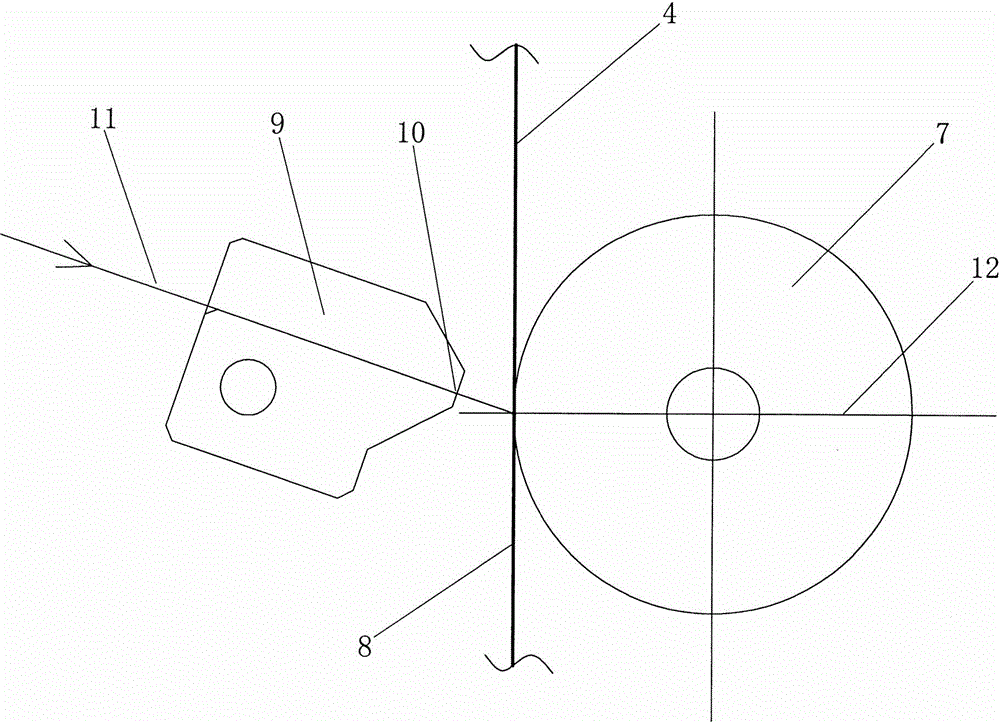

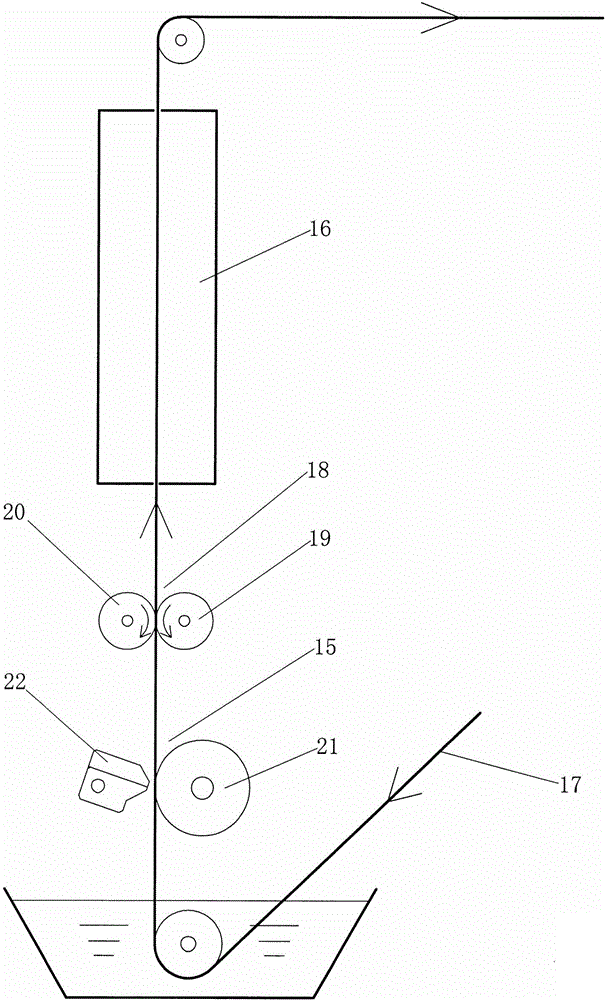

[0021] refer to Figure 1 ~ Figure 2 , this simple double-sided dip-coating metering device consists of a frame, a dip-coating tank 1 installed on the frame, a dip-coating tank guide roller 2, and a coating metering unit 3, wherein the coating metering unit 3 is located in the dip-coating Above the tank 1, the substrate 4 is conveyed vertically through the coating metering unit 3 after being output from the guide roller 2 of the dip coating tank, and passes through the double-sided dryer 5 vertically. It is characterized in that: the coating metering unit 3 is arranged on the substrate A metering roller 7 on one side 6 and an air knife 9 arranged on the other side 8 of the substrate, wherein the metering roller 7 is a driving roller driven by power, and the metering roller 7 forms a line contact with the one side 6 of the substrate, The air outlet 10 of the air knife 9 is located on the outside of the other surface 8 of the substrate, facing the position corresponding to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com