Automatic coloring and nailing machine for flip flops

A technology for flip-flops and coloring, which is applied to shoe-making machinery, footwear, clothing, etc., can solve the problem of no flip-flops with coloring, etc., so as to reduce the harm to human health, light in size, and uniform in coloring. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

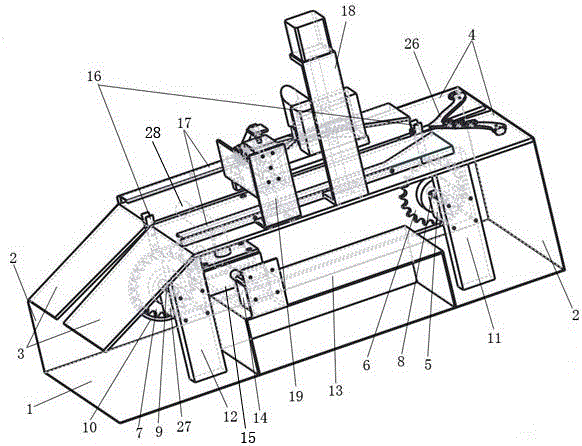

[0018] Such as figure 1 As shown, the frame is composed of base plate 1, first pillar 11 and second pillar 12, side plate 2 is vertically fixed on the edge of base plate 1, first stepper motor 5 and second stepper motor 27 are respectively fixed on the first pillar 11 and the second pillar 12, and are respectively connected with the first sprocket 6 and the second sprocket 7 through the first coupling 8 and the second coupling 9. The stepper motor has the advantages of convenient control, high operation precision, and high reliability. It is controlled by a single-chip microcomputer signal and driven by a stepper motor driver, which can accurately control the operation of the sprocket. By setting parameters in the control program, the running speed of the sprocket can be adjusted conveniently.

[0019] The chain 10 is matched with the first sprocket 6 and the second sprocket 7, and the clip 16 for driving the flip-flop strap 26 is fixed on the chain 10, and the controller dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com