Dynamic current sharing control method and circuit

A flow control and dynamic technology, applied in the direction of electrical components, output power conversion devices, etc., can solve the problems of undervoltage, reduced circuit reliability, affecting the dynamic response of the system, etc., to achieve simple circuit structure, reduced load current, and application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

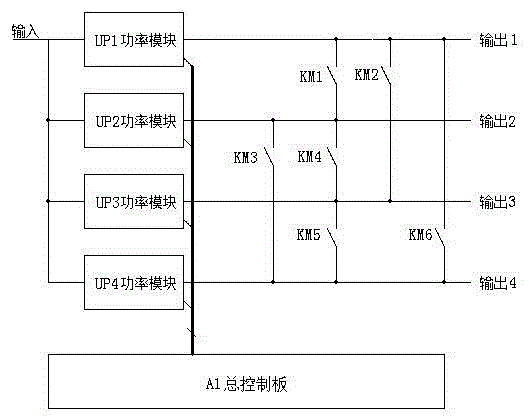

[0038] This embodiment is described by taking the rail transit vehicle-mounted inverter as an example. like figure 1Shown: The auxiliary power supply cabinet of the locomotive includes four groups of power modules UP1~UP4 working in parallel, the main control board A1, the control switches KM1~KM6, and each power module has its own sub-control board; among them, the main control board A1 is used for Collect the load current signals of power modules UP1~UP4 for quick calculation, and re-issue the load current distribution command of power modules UP1~UP4 to adjust the current limiting value of power modules UP1~UP4; the sub-control board is used to control the respective power modules UP1~UP4 The current; the control switches KM1~KM6 are used to control any dynamic combination between the power modules UP1~UP4, and random parallel connection. The connection relationship of all the above devices is as follows: the power modules UP1~UP4 are connected in parallel, the control swi...

Embodiment 2

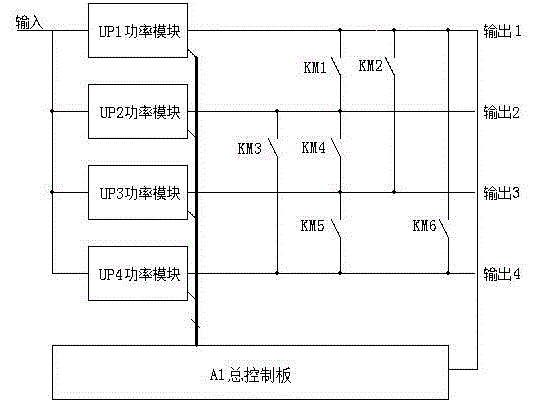

[0048] This embodiment is described by taking the rail transit vehicle-mounted inverter as an example. like figure 2 Shown: The auxiliary power supply cabinet of the locomotive includes four groups of power modules UP1~UP4 working in parallel, the main control board A1, the control switches KM1~KM6, and each power module has its own sub-control board; among them, the main control board A1 is used for Collect the load current signals of the power modules UP1~UP4 for quick calculation and re-issue the load current distribution instructions of the power modules UP1~UP4 to adjust the current limiting value of the power modules UP1~UP4; the main control board A1 is also used to obtain the power modules UP1~UP4 The total output current on the mains. The sub-control board is used to control the current of the respective power modules UP1, UP2, UP3, UP4; the control switches KM1~KM6 are used to control any dynamic combination between the power modules UP1~UP4, and random parallel co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com