U-shaped stator hybrid-excitation switch reluctance machine

A technology of switched reluctance motor and mixed excitation, which is applied in the direction of electrical components, electromechanical devices, electric components, etc. It can solve the problems of incomplete separation of magnetic circuits, reduced motor efficiency, long winding ends, etc., and achieves easy processing and maintenance, The effect of high power density and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

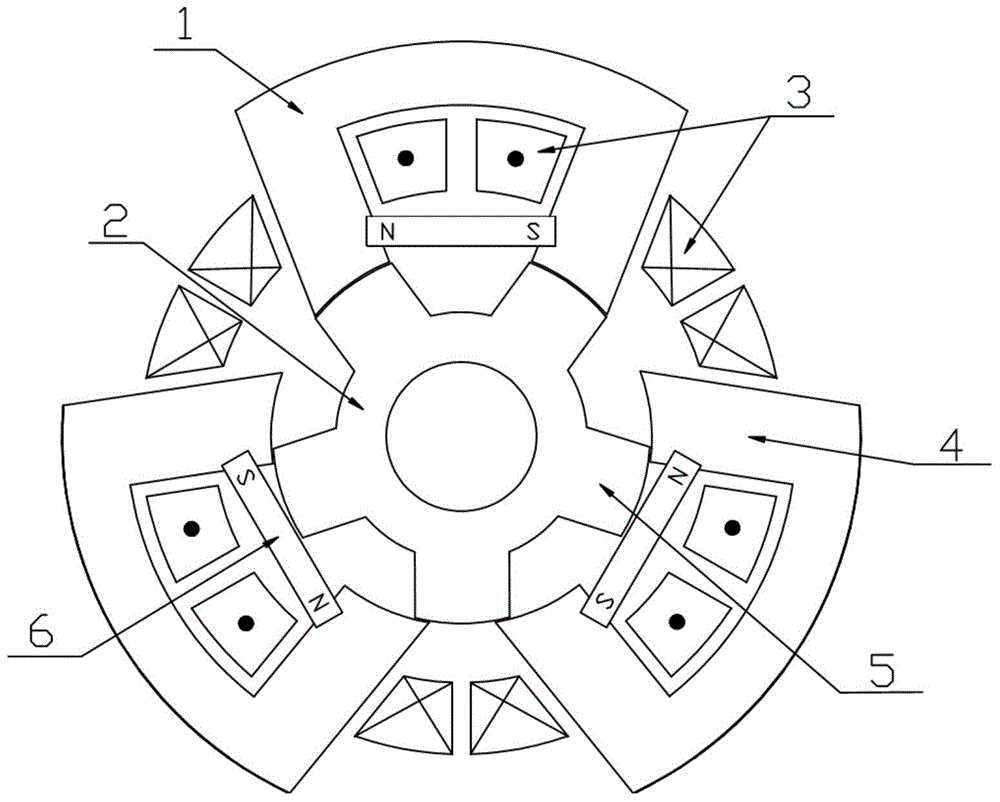

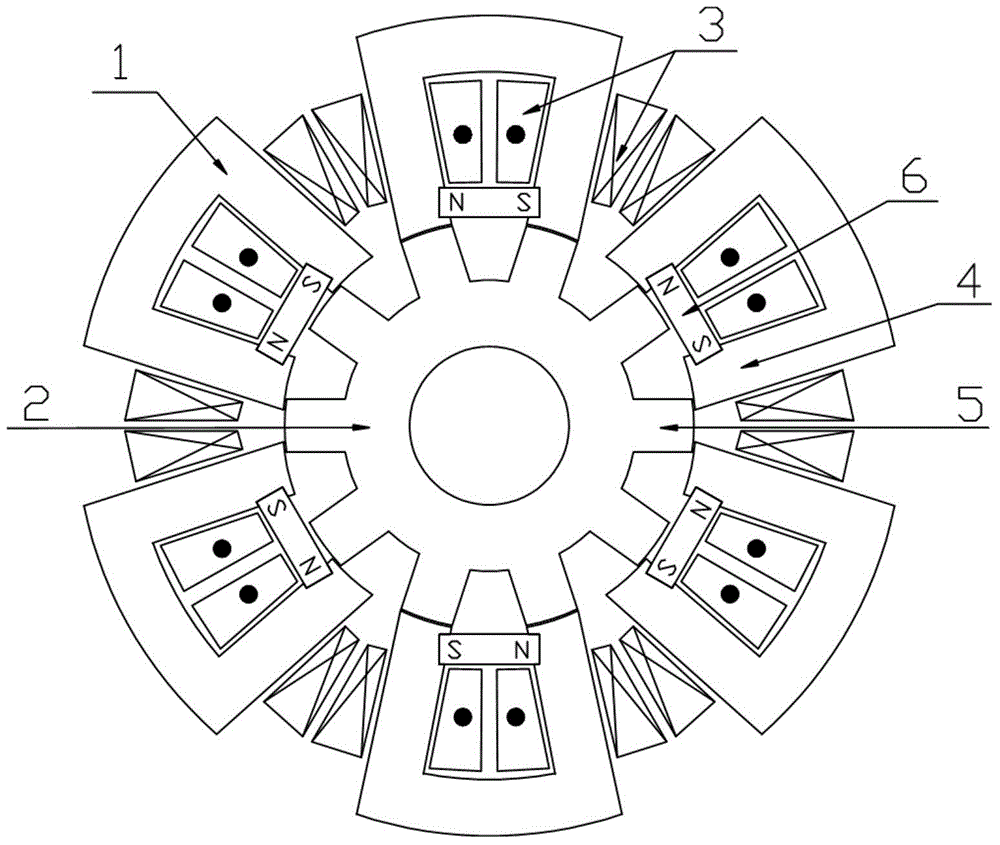

[0033] When the U-shaped stator hybrid excitation switched reluctance motor provided by the present invention has three phases, the motor can be divided into a three-phase 6 / 5 structure and a three-phase 12 / 10 structure, and the working principle is the same.

[0034] The cross-sectional structure of the U-shaped stator hybrid excitation switched reluctance motor of the three-phase 6 / 5 structure of the present invention is as follows figure 1 As shown, it includes U-shaped stator block 1 , rotor 2 , field winding 3 and permanent magnet 6 . Three U-shaped stator blocks 1 are evenly distributed in the circumferential direction of the rotor 2, and there is a permanent magnet installation groove at the notch of each U-shaped stator block 1, and the permanent magnet 6 is placed in the permanent magnet installation groove of the U-shaped stator block 1 , the permanent magnet 6 is tangentially magnetized, and the field winding 3 is wound on the two stator teeth 4 of each U-shaped sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com