Explosive Fuze Formed Explosion-proof Internet of Things Visual Monitoring System Device

A technology for monitoring systems and explosion-proof materials, which is applied in general control systems, control/regulation systems, program control, etc., to achieve the effects of reducing energy consumption, simple installation, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

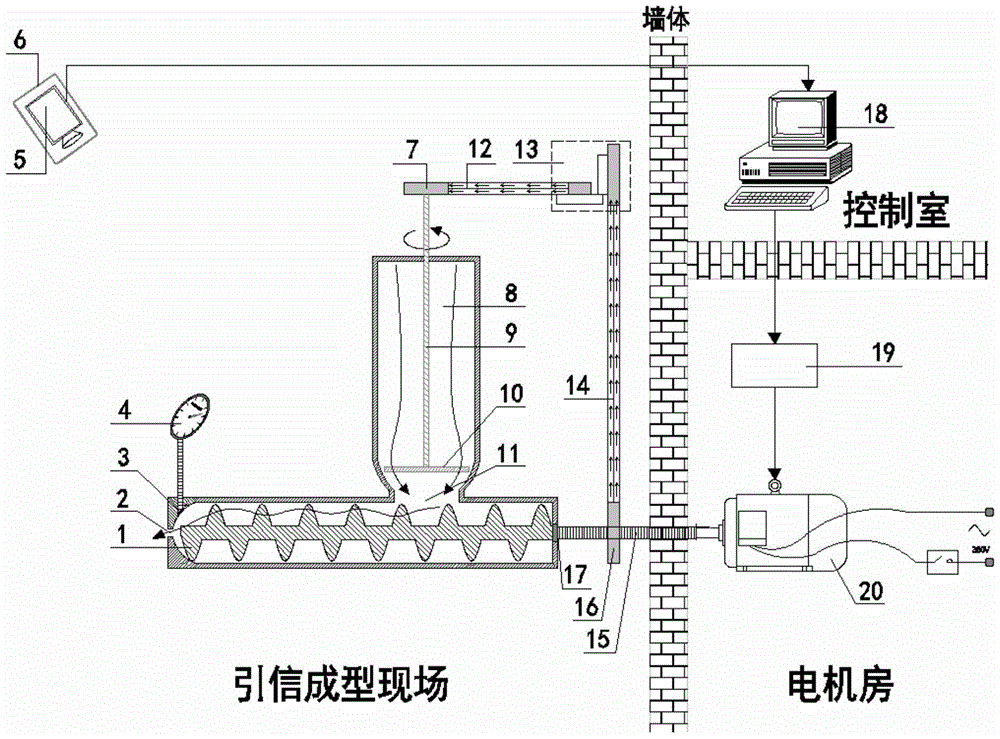

[0016] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

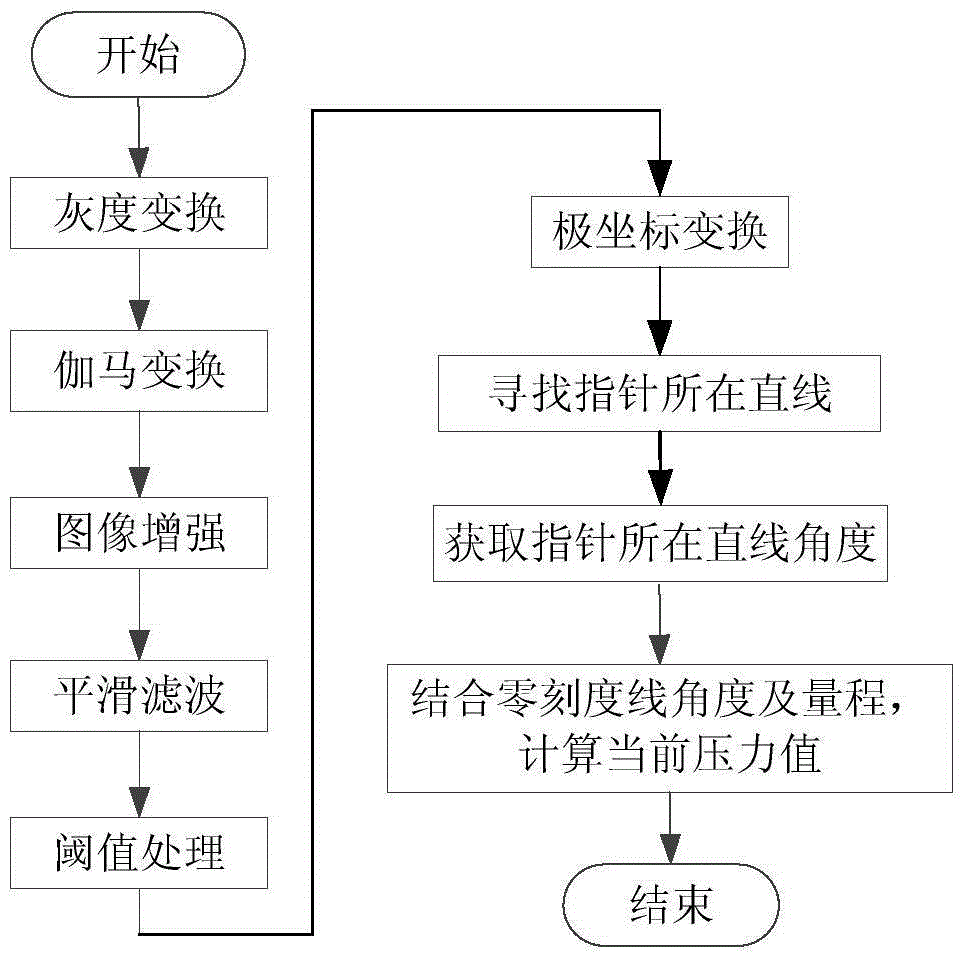

[0017] like figure 1 As shown, an explosive fuze forming explosion-proof Internet of Things visual monitoring system device according to the present invention mainly includes a fuze strip forming extrusion unit, an explosive blanking and mixing unit, a mechanical transmission unit, a pressure gauge detection and recognition unit, and a control unit.

[0018] Wherein, the fuze strip forming extrusion unit includes a transverse grooved spiral rod 1 located in the extrusion cavity and a trumpet-shaped extrusion hole 2 located at the left end of the extrusion cavity. The extrusion hole 2 can be adjusted according to the size of the required fuse To make a ruling, under the working state, the grooved spiral rod 1 pushes the material to move to the end where the extruded hole 2 is located, and extrudes the fuze bar through the extruded hole 2 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com