A thermocouple suitable for measuring flame temperature by dynamic method and its manufacturing method

A flame temperature and thermocouple technology, applied in the direction of measuring heat, thermometers, measuring devices, etc., can solve the problems of large thermal inertia coefficient of thermocouple time constant and insufficient sensitivity, so as to improve measurement accuracy and sensitivity, reduce deposition, reduce The effect of temperature measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

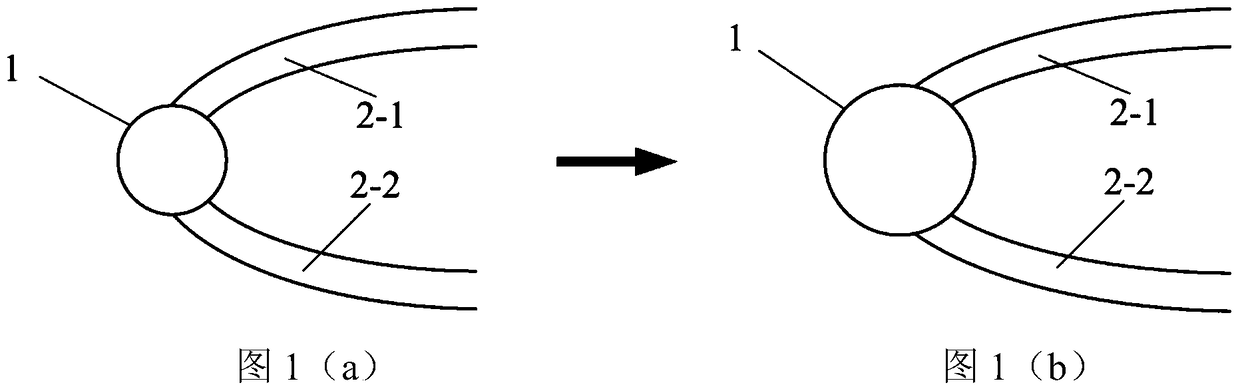

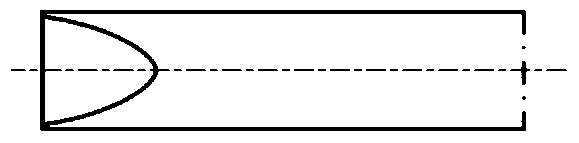

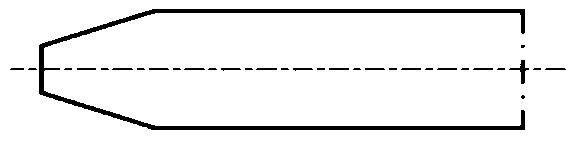

[0036] Refer to Figure 1~ Figure 6 , a thermocouple suitable for measuring the flame temperature by a dynamic method, comprising two thermocouple wires, a wire junction 1, an insulating sleeve 3, a protective sleeve 4 and a compensating wire, and the wire junction 1 consists of two The root thermocouple wire is welded and formed, and the described dual wire node 1 is disc-shaped, and the front end face and the rear end face of the described dual wire node 1 are parallel to each other;

[0037] The two thermocouple wires are the upper thermocouple wire 2-1 and the lower thermocouple wire 2-2 respectively, and the upper thermocouple wire and the lower thermocouple wire are respectively the positive pole and the negative pole of the thermocouple. The upper thermocouple wire 2-1 and the lower thermocouple wire 2-2 are symmetrically arranged up and down, the upper thermocouple wire 2-1 and the lower thermocouple wire 2-2 are arc-shaped, and the upper thermocouple wire 2 The arc a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com