Multifunctional and multi-shape ice pressing machine

A multi-shape, multi-functional technology, applied in the direction of making ice, ice storage/distribution, lighting and heating equipment, etc., can solve the problems of time-consuming, laborious and cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

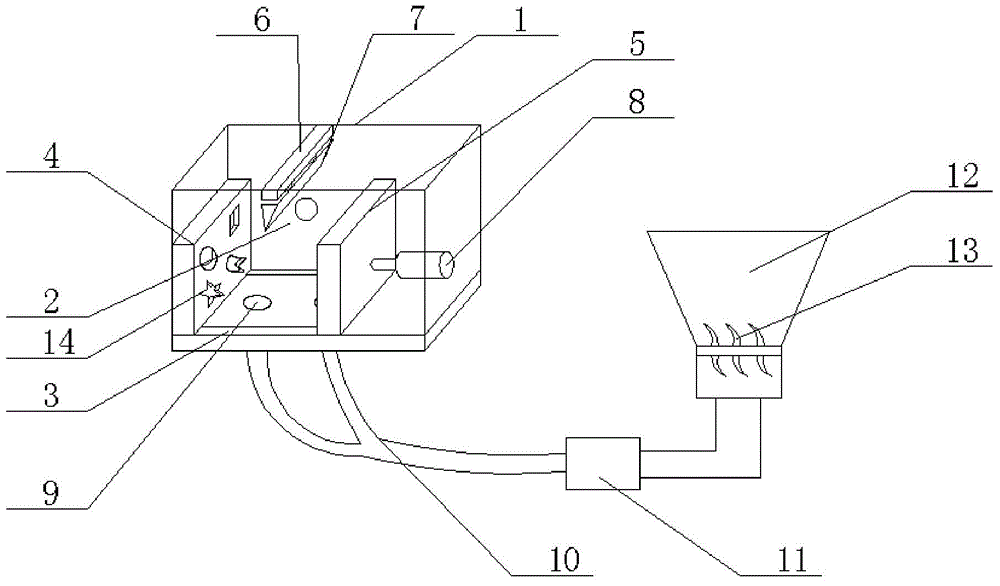

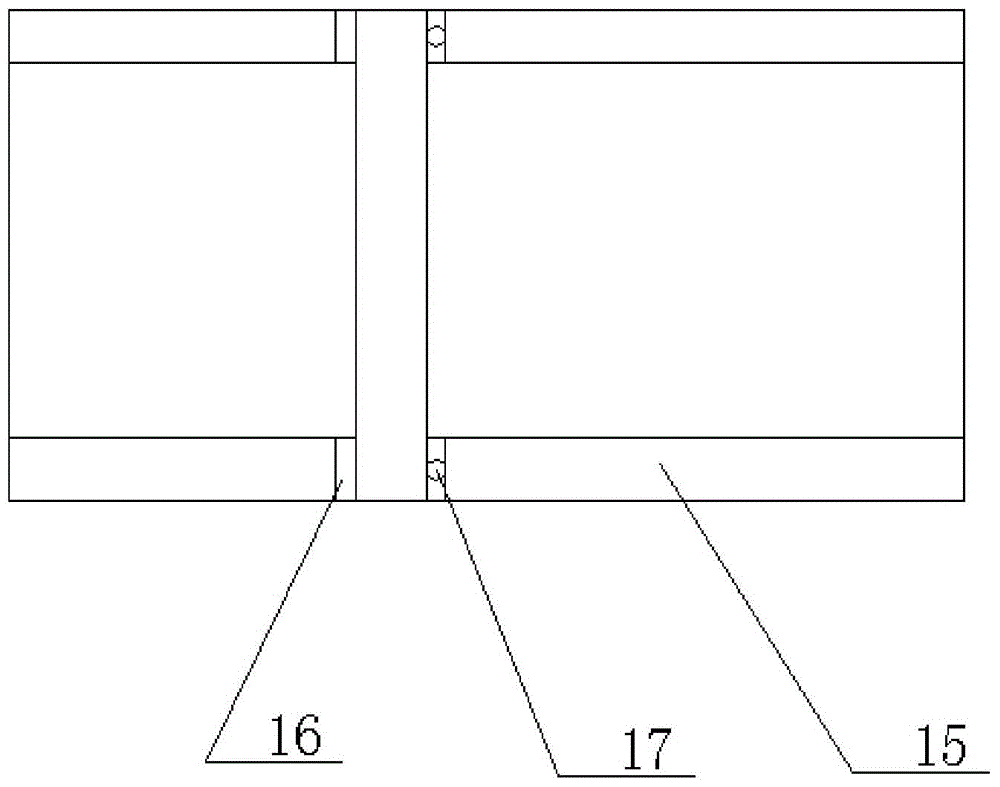

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] see figure 1 with figure 2 As shown, the technical solution adopted in this specific embodiment is: it includes a body 1, a discharge outer cover 2, a slide rail 3, a fixed template 4, a sliding template 5, a tool holder 6, a tool 7, a push hydraulic rod 8, a raw material Inlet 9, feeding pipe 10, feeding pump 11, hopper 12, crushing mechanism 13, model tank 14; one side of the body 1 is provided with a discharge outer cover 2, and the inner bottom side of the body 1 is provided with a slide rail 3 for sliding One end of the rail 3 is fixedly connected with a fixed formwork 4, and the slide rail 3 is movably connected with a sliding formwork 4, and the outer side of the sliding formwork 4 is connected with a push hydraulic rod 8, which is arranged on the inner side wall of the body 1, and the body 1 The upper part is provided with a tool holder 6, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com