Wheel body with power source arranged internally and method for internally arranging power source of wheel body

A power source and wheel body technology, applied in the direction of engines, elastic engines, machines/engines, etc., can solve the problems that affect the overall appearance of toys, structural design, affect the integrity of toys, and the aesthetic effect of plasticity, so as to enrich the product structure and simplify The effect of product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

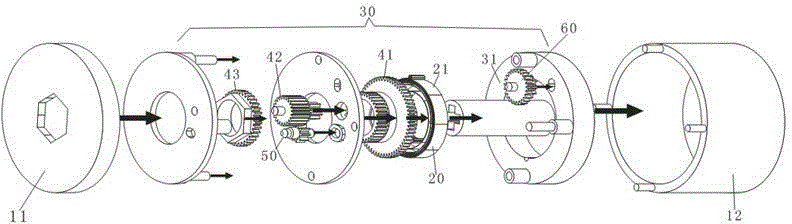

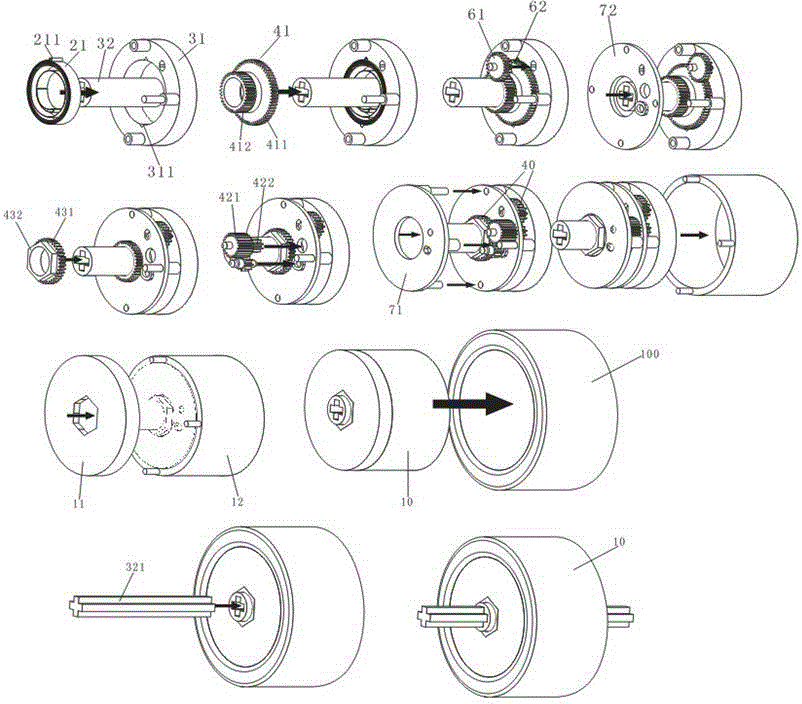

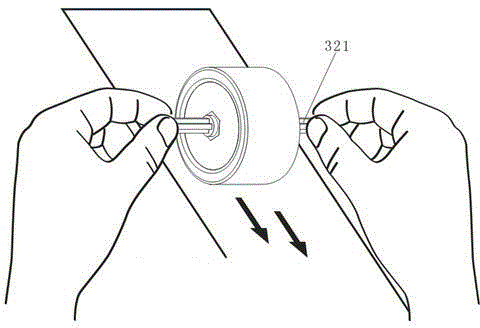

[0024] Such as Figures 1 to 6 As shown, a wheel body with a built-in power source includes a turning wheel box 10 , a power source 20 and a power conversion unit 30 , wherein the power source 20 and the power conversion unit 30 are arranged in the turning wheel box 10 .

[0025] The power conversion unit 30 is connected between the wheel box 10 and the power source 20 .

[0026] The outer surface of the rotating wheel box 10 is provided with a tire layer 100, so that the wheel body of the present invention has no difference in appearance from the traditional wheel body.

[0027] The tire layer can be made of rubber material, and the tire layer can be designed as a solid structure or a hollow inflatable structure.

[0028] When working, the power source 20 generates power, and the power conversion unit 30 transmits the power generated by the power source 20 to the turning wheel box 10 so that the turning wheel box 10 can rotate around its axis.

[0029] The main design idea ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com