Safety connector for oil field working

A safety joint and operation technology, which is applied in drilling equipment, earth-moving drilling, drill pipe, etc., can solve the problems of difficult opening of safety joints, low success rate, and inability of safety joints to achieve separation function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to solve the problem in the prior art that the safety joints for oil field operations are easily affected by well conditions during well operations, and the shear nails of the safety joints for oil field operations are easily broken in the middle, a safety joint for oil field operations with a new structure is provided. joints to improve the controllability of the safety joint separation function for oilfield operations.

[0056] The technical solution of the embodiment of the present invention is to solve the above-mentioned technical problems, and the general idea is as follows:

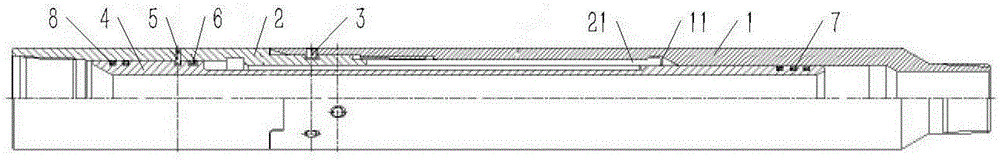

[0057] A safety joint for oilfield operations provided by the present invention includes:

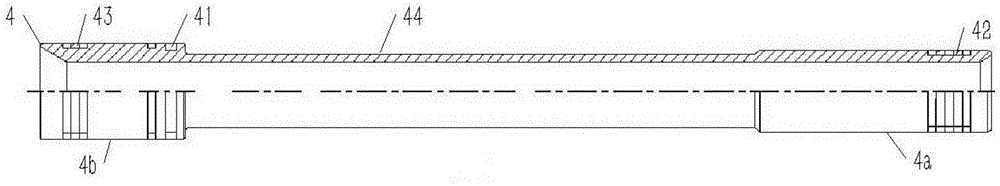

[0058] a first connecting pipe, the channel of the first connecting pipe is provided with a first limiting structure;

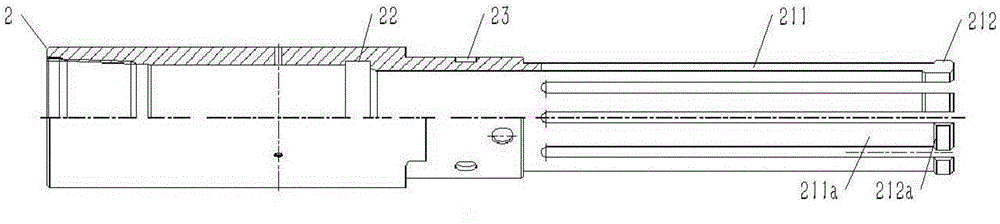

[0059] A second connecting pipe, one end of the second connecting pipe is provided with a second limiting structure, and one end of the second connecting pipe is inserted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com